- 74 -

6 ELECTRODE WELDING (MMA)

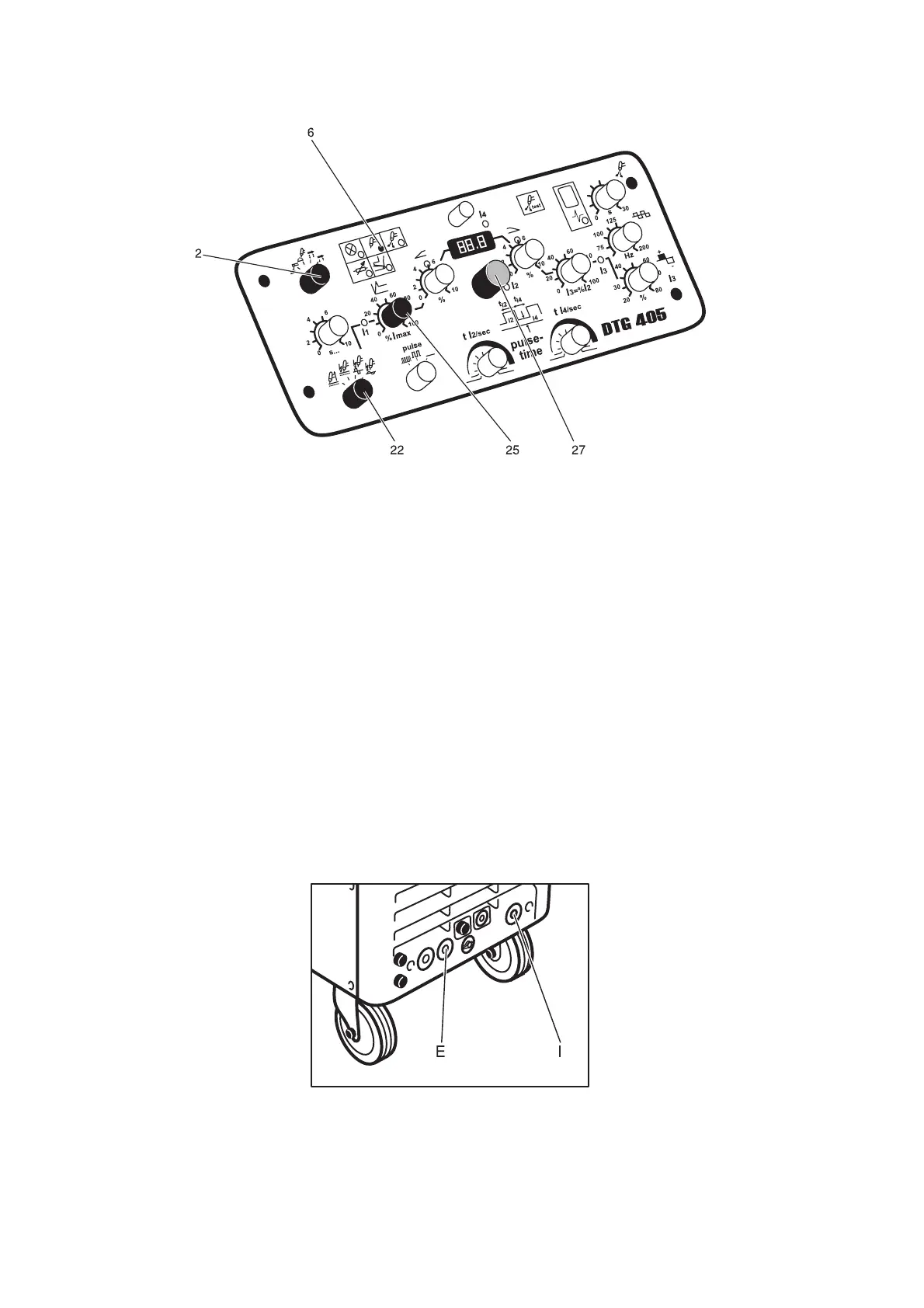

6.1 SETTINGS ON THE CONTROL PANEL WHEN ELECTRODE WELDING

The polarity of the electrode depends on the type of electrode and the welding process. Pay at-

tention to the producer’s instructions on the electrode package.

Application of pulsed welding current is possible.

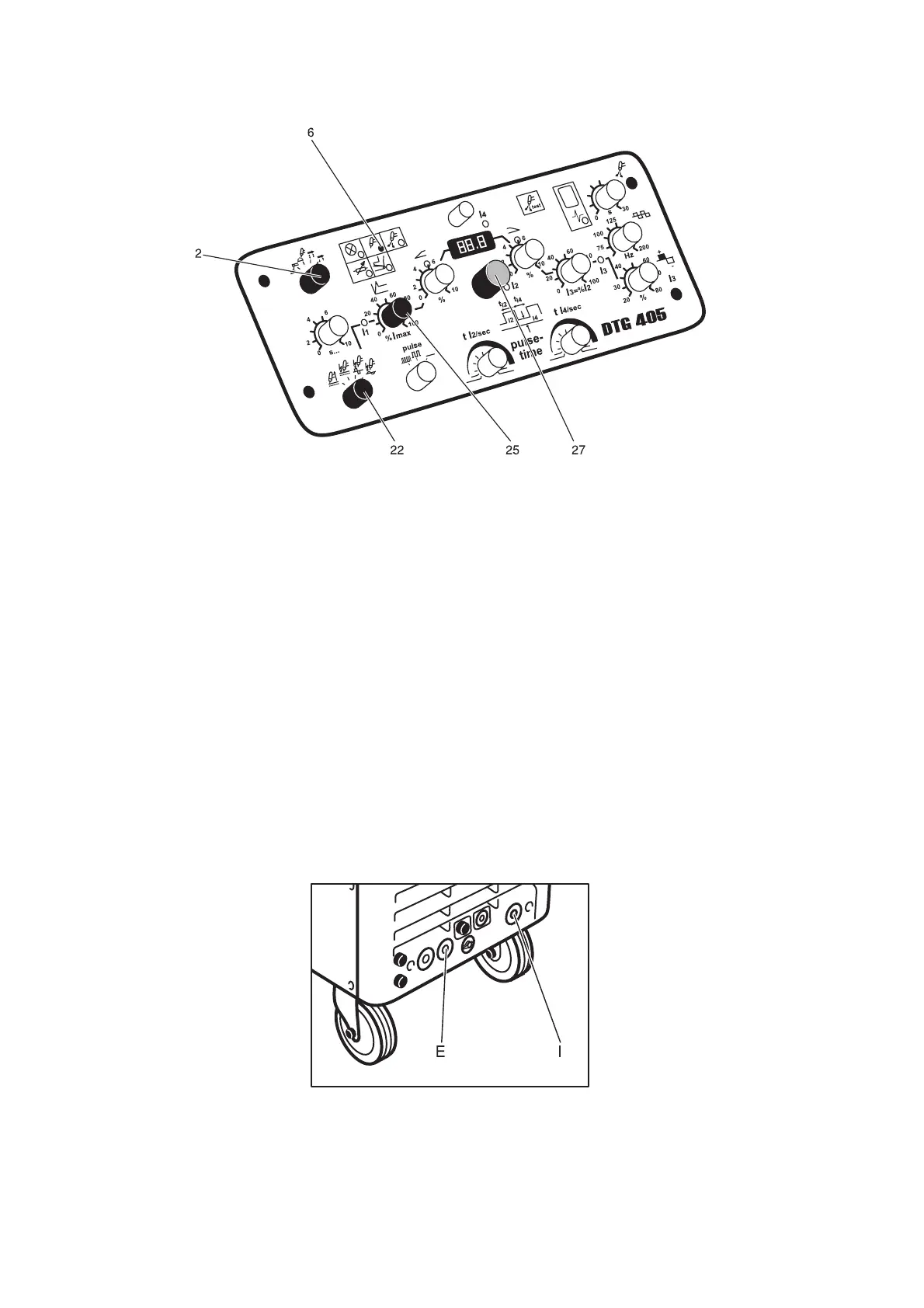

1. Connect the welding current cable to the welding current socket (E) and (I) with reference to

the polarity.

2. Set mode selection switch (2) to electrode welding.

Light emitting diode (6) indicates that voltage is applied to the welding current sockets (E)

and (I).

3. Set the desired welding current type with welding current selection switch (22).

4. Set Soft-Hot-Start function (ignition current) using the potentiometer I1 (25).

The ignition current is a percentage of the power sources maximum output of 400 A (ie. a

setting of 25% will give an ignition current of approximately 100A)

Set this control to a level that provides easy ARC.

5. Set welding current value I2 using the potentiometer (27).

The welding current can be also controlled by a hand or foot operated remote control.

Loading...

Loading...