- 77 -

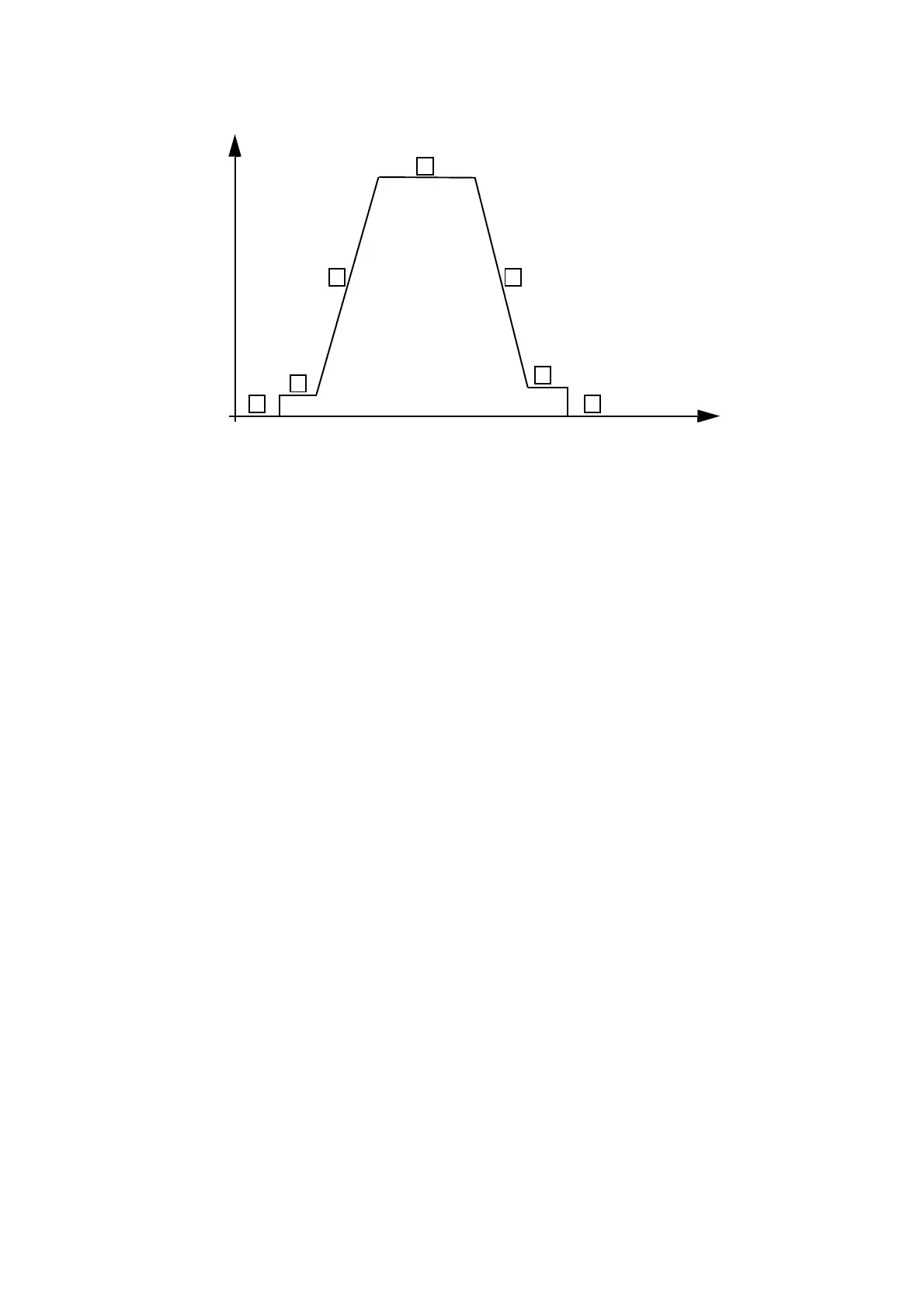

TIG four-stroke welding process

1. The gas pre-flow time has an internal fixed default value.

2. Set ignition current I1 using the potentiometer (25).

3. Set Up-Slope using the potentiometer (9), at maximum (I2=400A) a ramp time of 10s is

obtained. The ramp time is dependant on the set welding current I2.

4. Set welding current I2 using the potentiometer (27).

5. Set Down-Slope using the potentiometer (14), at maximum (I2=400A) a ramp time of 10s is

obtained. The ramp time is dependant on the set welding current I2.

6. Set final current I3 using the potentiometer (30)

7. Set gas post-flow time using the potentiometer (18) 0.2–30 s.

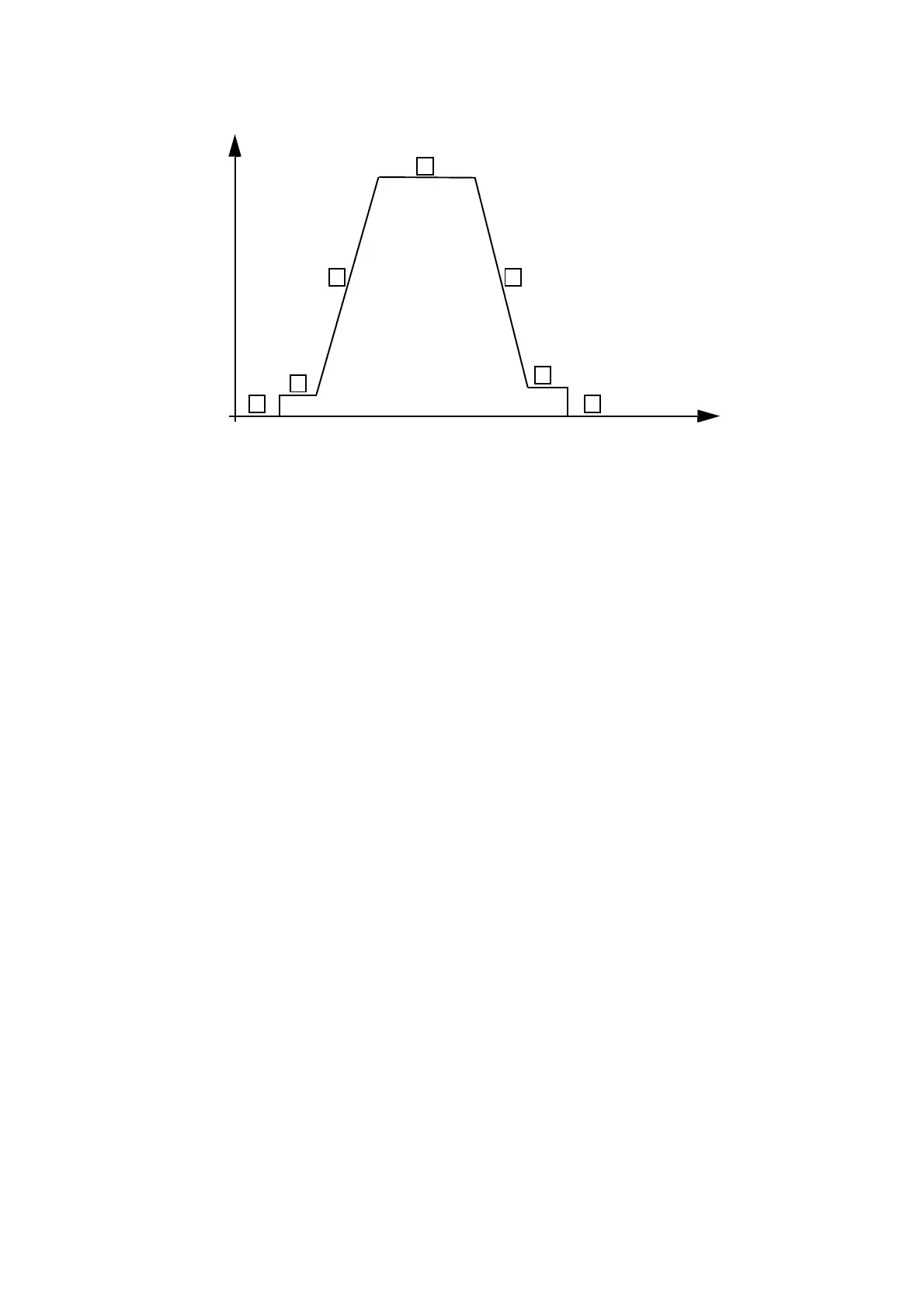

7.1.3 TIG TWO-STROKE WELDING

Step 1: By pressing the torch switch the gas flows for the preset time and the ARC ignites at a

current level set by potentiometer I1 (25).

After a fixed time the current rises at a rate set by the up-slope control (9) to the welding

current value set by the potentiometer I2 (27).

Step 2: By releasing the torch button, the current slopes down to the set final current in the time

set using the potentiometer Down-Slope. Afterwards, the arc extinguishes and the gas

post-flow time runs off.

2

4

5

6

7

3

1

Loading...

Loading...