C

17

630791 DS MKII INSTALLATION MANUAL

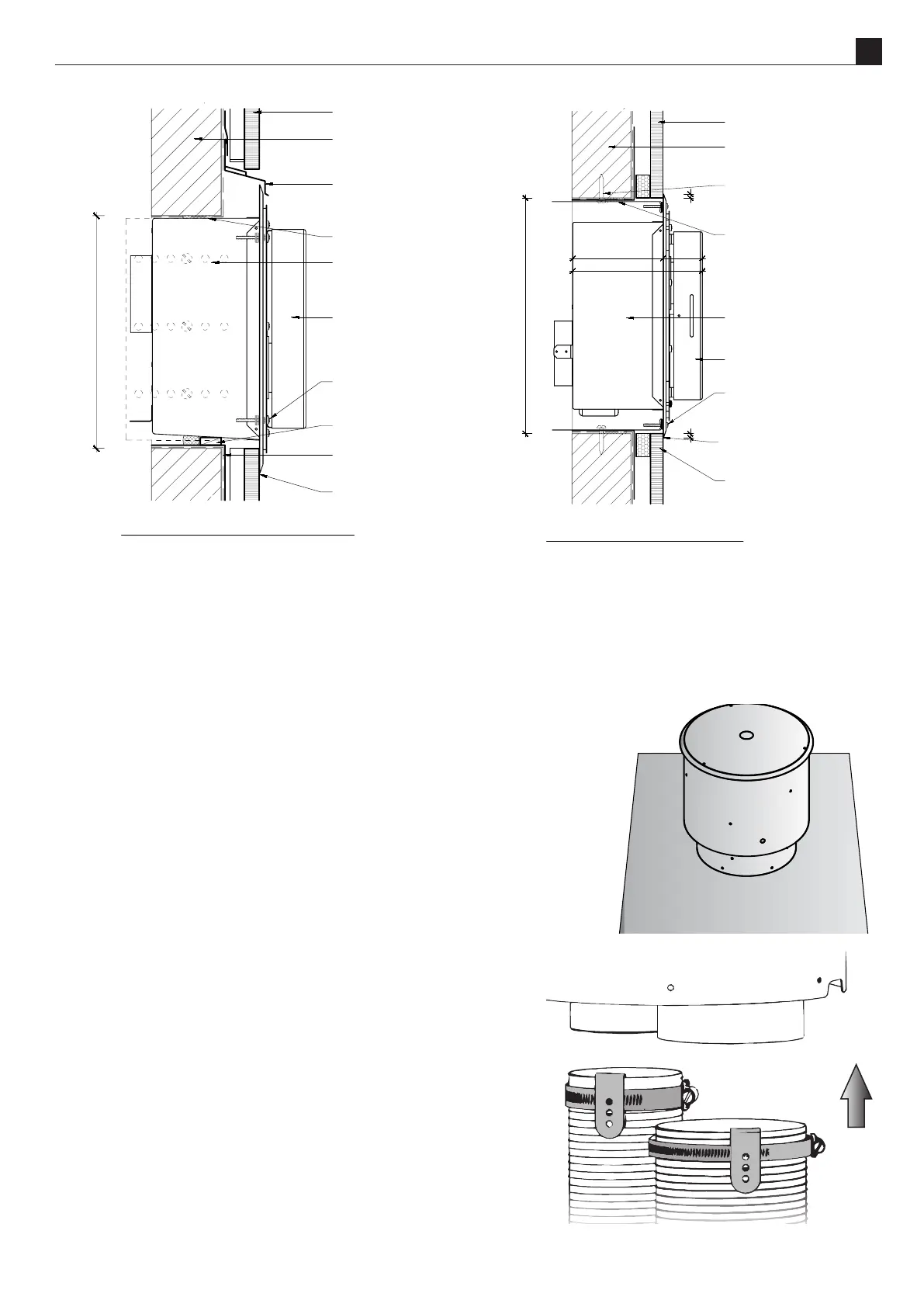

Head and Sill scale 1:5

framing member with

wall wrap and flashing

tape over

cladding on cavity

batten

typical head flashing with

stop ends to comply with

relevant building code

horizontal powerflue

unit

terminal fixing brackets

(shown dashed) fixed

to framing

flashing tape over wall

wrap to opening

seal air gap to opening

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

packer to lift terminal off

sill

sill cover to cladding to comply

with relevant building code

300 min

360 min

10

cladding on cavity

batten

10

horizontal powerflue

unit

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

terminal fixing

brackets screw fixed

into framing

framing member with

wall wrap and flashing

tape over

continuous sealant strip

to jambs

scriber or plug may be

required - dependent on

cladding type

seal air gap to opening

cowl

198

138 60

scale: date:

ecn:

drawn:

drawing no:

revision:file:

Horizontal Powerflue Detail

as shown ECN-2155 EDA-0006 MGD-Series FLUE Master File.dwg

V. 02 08.12.2017

Jamb scale 1:5

framing member with

wall wrap and flashing

tape over

cladding on cavity

batten

typical head flashing with

stop ends to comply with

relevant building code

horizontal powerflue

unit

terminal fixing brackets

(shown dashed) fixed

to framing

flashing tape over wall

wrap to opening

seal air gap to opening

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

packer to lift terminal off

sill

sill cover to cladding to compl

with relevant building code

300 min

360 min

10

cladding on cavity

batten

10

horizontal powerflue

unit

terminal screw fixed to flange

with flange fixed to studs at

fixing brackets

terminal fixing

brackets screw fixed

into framing

framing member with

wall wrap and flashing

tape over

continuous sealant strip

to jambs

scriber or plug may be

required - dependent on

cladding type

seal air gap to opening

cowl

198

138 60

scale: date:

ecn:

drawn:

drawing no:

revision:file:

Horizontal Powerflue Detail

as shown ECN-2155 EDA-0006 MGD-Series FLUE Master File.dwg

V. 02 08.12.2017

C4

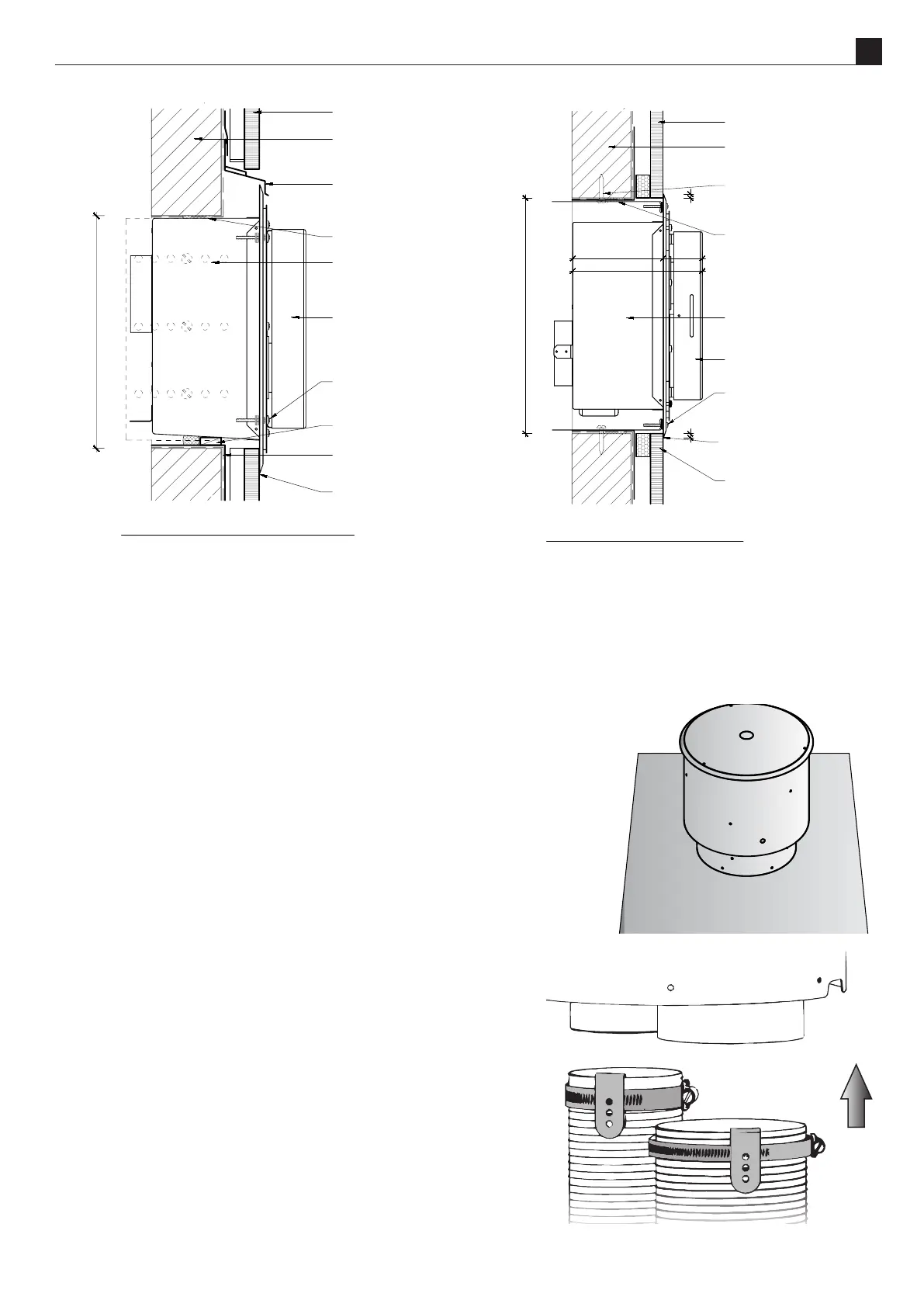

The UVP is designed to have the enclosure containing the fan unit mounted externally. Escea recommends this

install for a UVP powerue; an example is shown below.

Ensure the 43mm restricon plate is installed on the inlet.

The cowl surround should be xed in place as shown right.

Mount the UVP kit to the top of a chimney ashing plate or penetrate the

roof with an oponal ue liner accessory and t the UVP kit over the ue

liner, sealing the penetraon with a deckte or similar ashing.

Ensure the terminal is vercal and rigidly mounted and the exi ue

aached below is xed to the terminal spigots using the supplied hose

clamps and aid clips.

Place the clamp over the exi ue and the clip over this. Make sure

the exi tube has been stretched out as far as possible where the

hose band clamps are going to be aached (not sll compressed).

Slide the exi tube over the spigot and hold it in place by drilling

one hole through the spigot using the clip guide hole and riveng

the three components together.

NOTE: If this install is impraccal for your situaon see

informaon regarding an internal install of the UVP, go to

secon C5 on page 18.

Loading...

Loading...