3 Mechanical installation

20 Festo – GDCP-CMMS-AS-G2-HW-EN – 1310NH – English

For vertical mounting onto a control cabinet mounting plate:

• Mount the acc ompanying mounting brackets to the

CMMS-AS -...-G2 motor controller.

The two mounting brackets are part of the radiator profile and

transfer heat to the mounting plate.

The motor controllers of the CMMx family are designed in such

a way that they c an be mounted on a heat-dissipating mount-

ing plate if used as intended and installed correctly.

• Use the motor controller exclusively as an installed device

in a control cabinet:

– The mounting position is vert ical with th e po wer supply

lines [X9] leading upwards

– Mount to the mounting brackets with M5 screws.

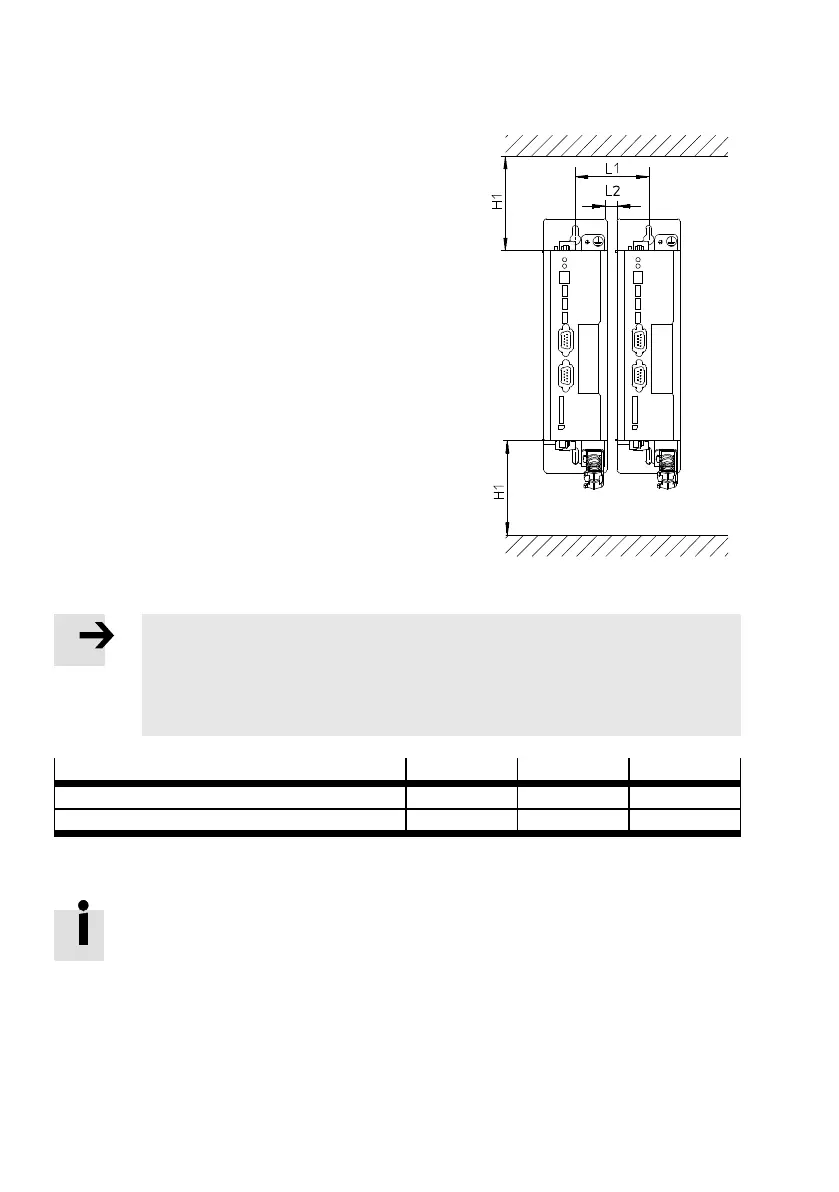

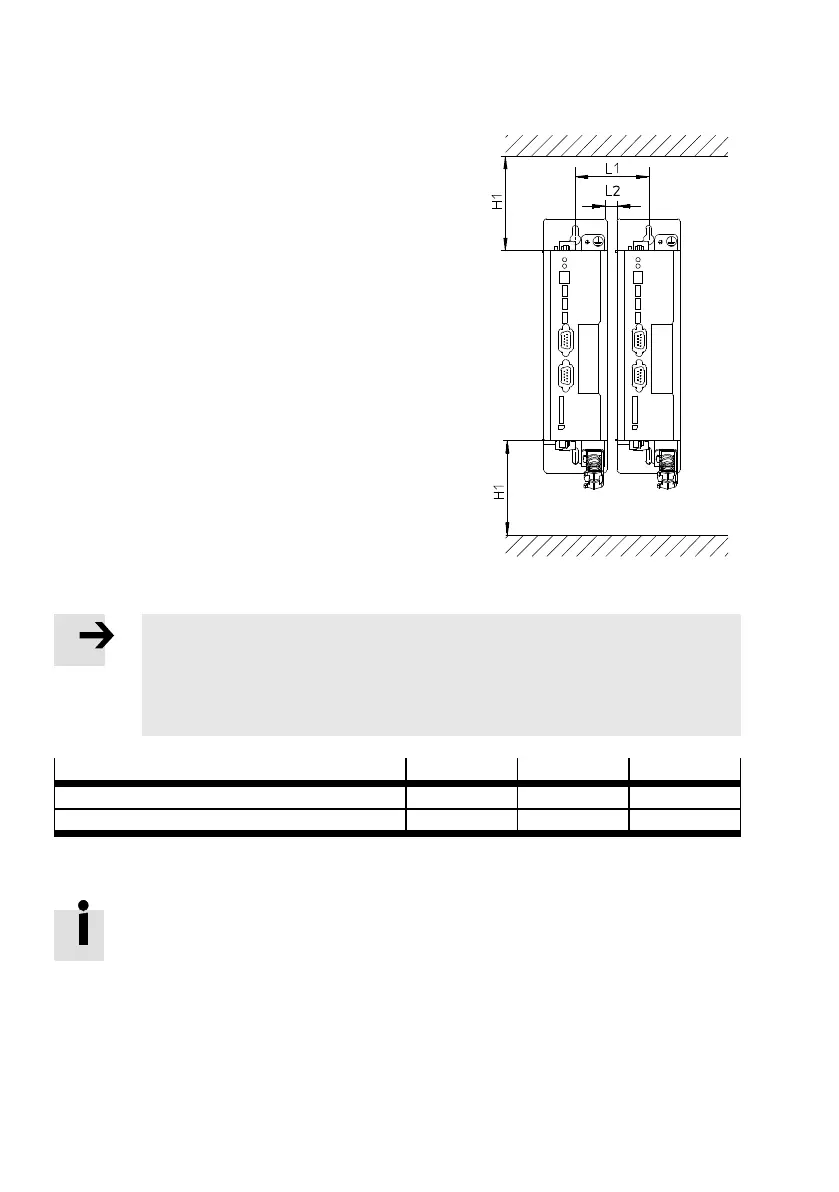

Fig. 3.2 Installation clearance

Note

An exc essive temperature increase results in premature aging or damage to the motor

controller.

• Observe the specified installation clearances to ensure sufficient ventilation

( Tab. 3.2).

Installation clearance

H1

1)

L1 L2

– at an output of 400 W [mm] 100 70 10

– at a rated output of 600 W [mm] 100 140 80

1) Recommendation for optimum wiring of the motor and encoder cable: Installation clearance H1 at the bottom = 150 mm.

Tab. 3.2 Installation c learance

The specified installation clearance L1 = 70 mm relates to an average motor output in

continuous operation (S1 operation ac cording to IEC 60034-1). When subjected to a high-

er output, the c learance L1 = 70 mm is sufficient under the following c onditions:

– The motor is operated at a higher peak load in intermittent operation ( S 3/S 4 opera-

tion according to I EC 60034-1: ac celeration, constant movement with a low load, brak-

ing).

– An excessive temperature increase of the motor c ontroller is prevented by forced

ventilation.

Loading...

Loading...