4 Electrical installation

40 Festo – GDCP-CMMS-AS-G2-HW-EN – 1310NH – English

4.9 Power supply [X9]

4.9.1 Protection against electric shock through protective extra-low voltage (PELV):

Warning

Danger of electric shock

• Only use PELV circuits in acc ordance with I EC/EN 60204-1 (protective extra-low

voltage, PE LV) for the electrical power supply.

Also obser ve the general requirements for PE LV circuits as per IEC/EN 60204-1.

• Only use voltage sources which guarantee reliable electrical isolation of the operat-

ing voltage in accordance with I EC/E N 60204-1.

The use of PELV circuits ensures protection from electric shock ( protection from direct and indirect

contact) in ac c ordance with IEC/EN 60204-1 ( Electrical equipment of machines, General requirements).

A 24 V power supply unit used in the system must satisfy the requirements of EN 60204-1 for DC power

supply (behaviour during power interruptions, et c.).

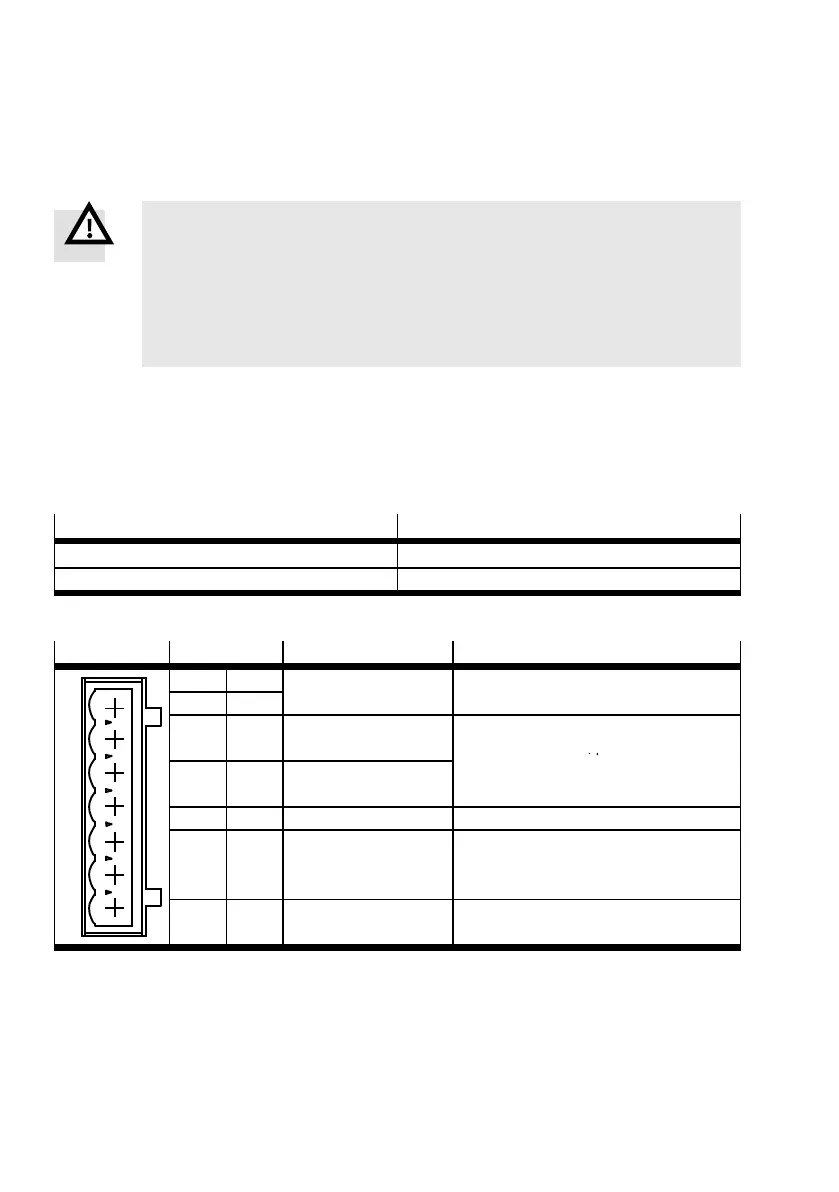

4.9.2 Pin allocation

Process valve

Version

[X9] on the motor controller Phoenix Contact - MSTBA 2.5/7-G-5.08 BK

Counterplug (plug set NEKM-C-4) Phoenix Contact - MSTB 2.5/7-ST-5.08 BK

Tab. 4.21 Connection, power supply

[X9]

Pin Value Description

1

2

3

4

5

6

7

1 L1 single-phase

95 ... 250 V AC

Mains voltage connection for

intermediate c ircuit voltage

2 N

3 ZK + 320 V DC

(max. 400 V DC)

Connection for the external braking

resistor R

BR

› 100 Ω , parallel to the

4 BR-CH 0 V/400 V,

max. 4 A

internal braking resistor,

Not short-circuit proof against L1, N, PE

5 PE PE Mains-side PE c onnection

6 24 V +24 V/1.7 A Supply for the control section, with

DCDC converter, DOUT0 to DOUT3 and

holding brake, max. 1.7 A

7 0V GND Common reference potential for the logic

power supply and control section

Tab. 4.22 Pin allocation: voltage supply [X9]

Loading...

Loading...