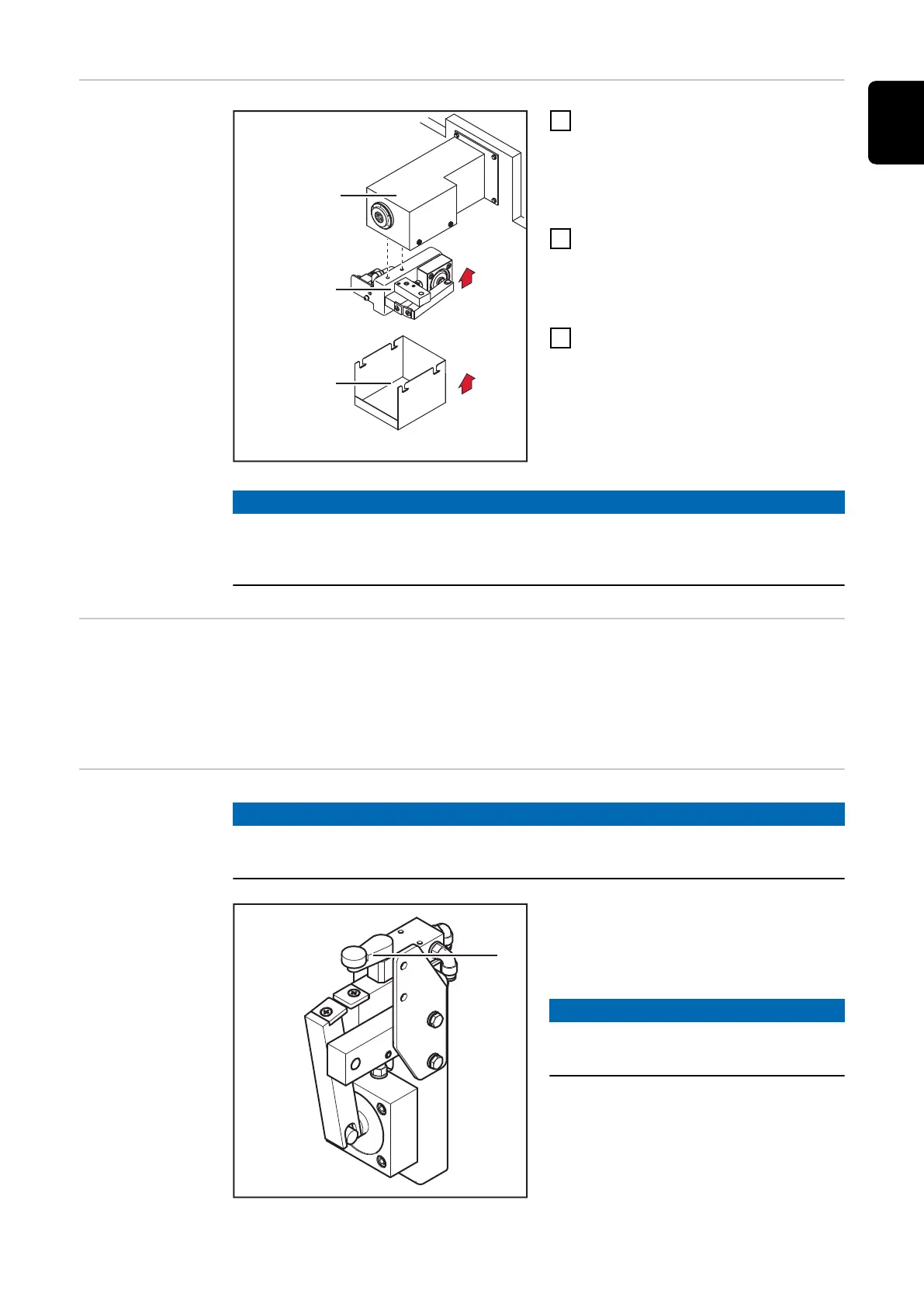

Fitting the wire

cutter to clean-

ing unit P

1

Screw the wire cutter (1) to the

cleaning unit (2) using 2 screws, 2

washers, 2 lock washers and 2 nuts

as shown. The installer is respons-

ible for selecting the right screws,

washers, lock washers and nuts

2

If using an electrically controlled

wire cutter: Plug the wire cutter

connecting cable into the wire cut-

ter connection socket on the

cleaning unit

3

Attach the spatter tray for welding

residues (3) to the wire cutter

NOTE!

The wire cutter cannot be supplied with compressed air from the cleaning unit.

The wire cutter must be supplied with compressed air from a separate supply

line.

Maximum wire

diameter

Wire electrodes with a diameter of up to 1.6 mm (0.063 in.) can be cut by the

wire cutter.

Two wire electrodes with a diameter of up to 1.6 mm (0.063 in.) can be cut in the

case of twin applications.

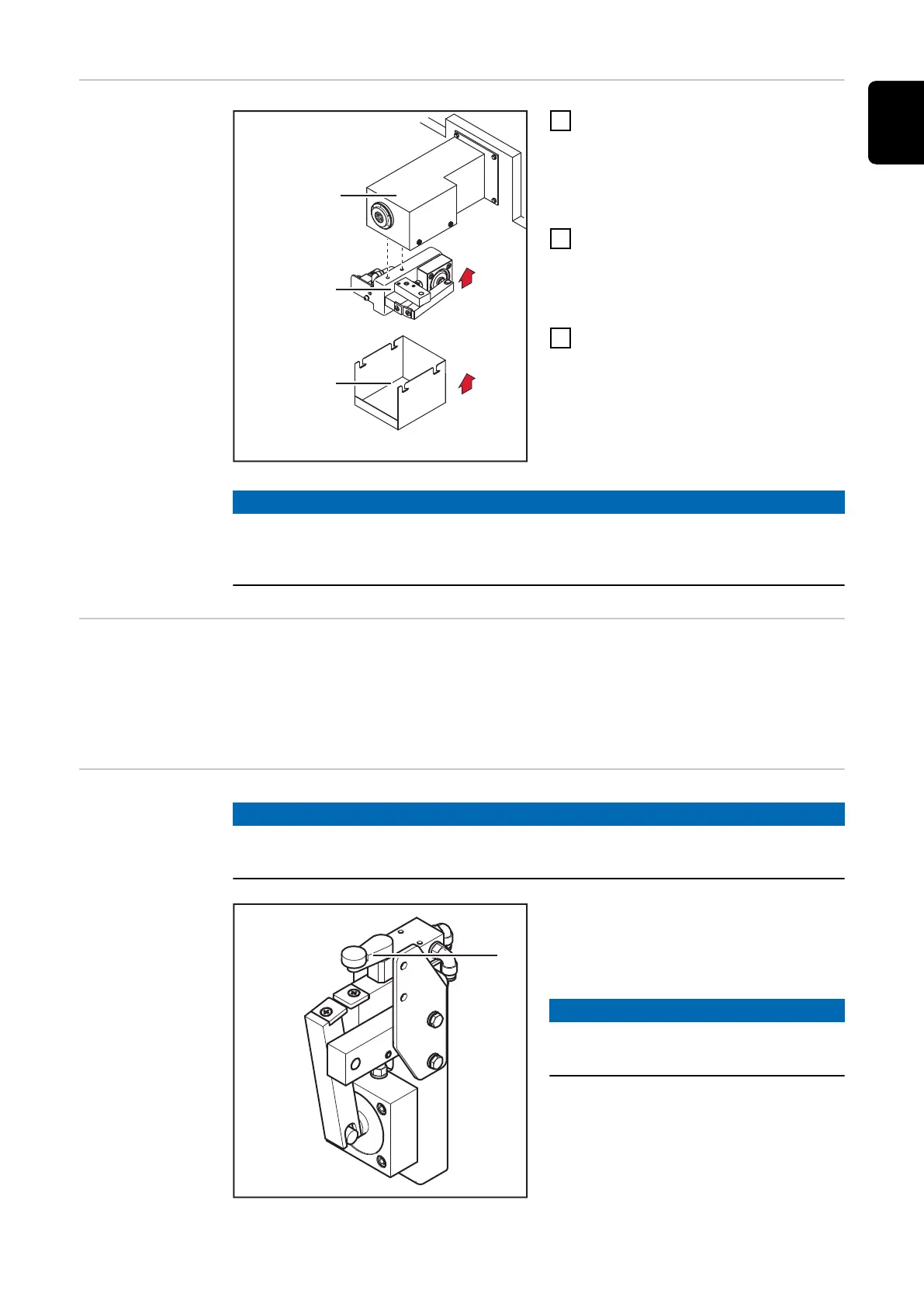

How the mech-

anically con-

trolled wire cut-

ter works

NOTE!

If you change over to a new welding torch, the mechanically controlled wire cut-

ter must be reset!

If a torch body pushes the valve lever

(1) to the side by more than 15° with

the gas nozzle, the wire cutter is activ-

ated and the wire electrode is cut.

NOTE!

The wire electrode is cut while the

torch body is moving.

49

EN

Loading...

Loading...