3

Depending on the application, hold the welding torch in the dipping bowl for

approximately 1 - 4 seconds so that any air in the torch can escape and the

torch can cool sufficiently

4

Raise the welding torch back to its original position above the dipping bowl

5

Allow the welding torch to drip for approximately 1 - 4 seconds or blow down

it with compressed air using the hosepack before bringing it back to its ori-

ginal position for cleaning

Cleaning the gas

nozzle tip - de-

tailed descrip-

tion

NOTE!

During the cleaning operation, blow out the welding torch with compressed air

through the hosepack - any remaining dirt or parting agent is removed.

NOTE!

Ensure that the gas nozzle does not touch the housing components of the clean-

ing opening at any time.

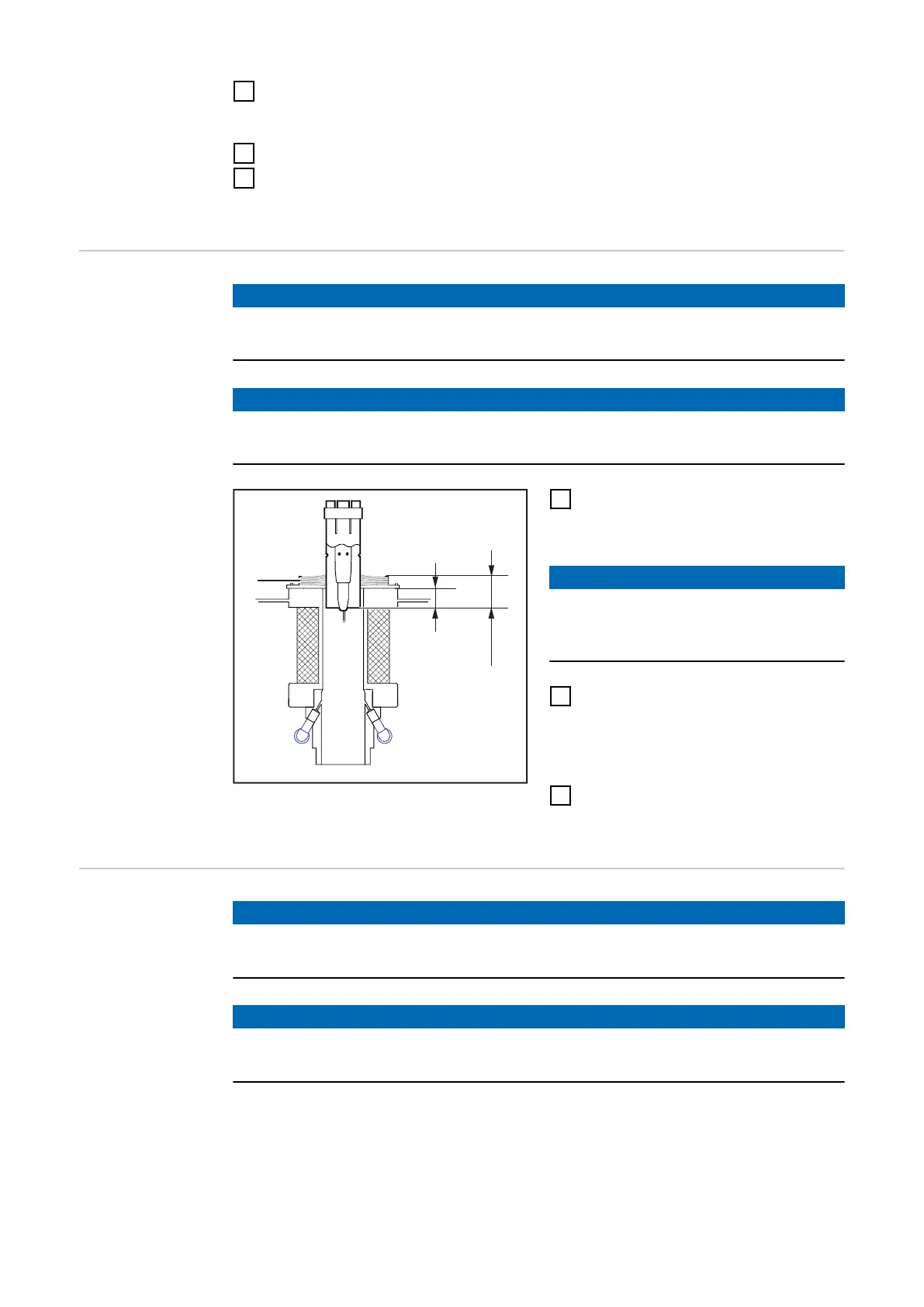

25 mm

(0.98 in.)

15 mm

(0.59 in.)

(1)

1

Position the welding torch approx.

40 mm (1.57 in.) centrally above

the middle of the cleaning opening

NOTE!

If the brush seal (1) is not fitted, note

the changed reference point when po-

sitioning the welding torch.

2

Insert welding torch vertically into

cleaning opening.

-

The optimum immersion depth

for the tip of the gas nozzle is

25 mm (0.98 in.)

3

Begin cleaning and hold the weld-

ing torch in the cleaning position

for approximately 1 second

Cleaning the

nozzle fitting -

detailed descrip-

tion

NOTE!

During the cleaning operation, blow out the welding torch with compressed air

through the hosepack - any remaining dirt or parting agent is removed.

NOTE!

Ensure that the gas nozzle does not touch the housing components of the clean-

ing opening at any time.

66

Loading...

Loading...