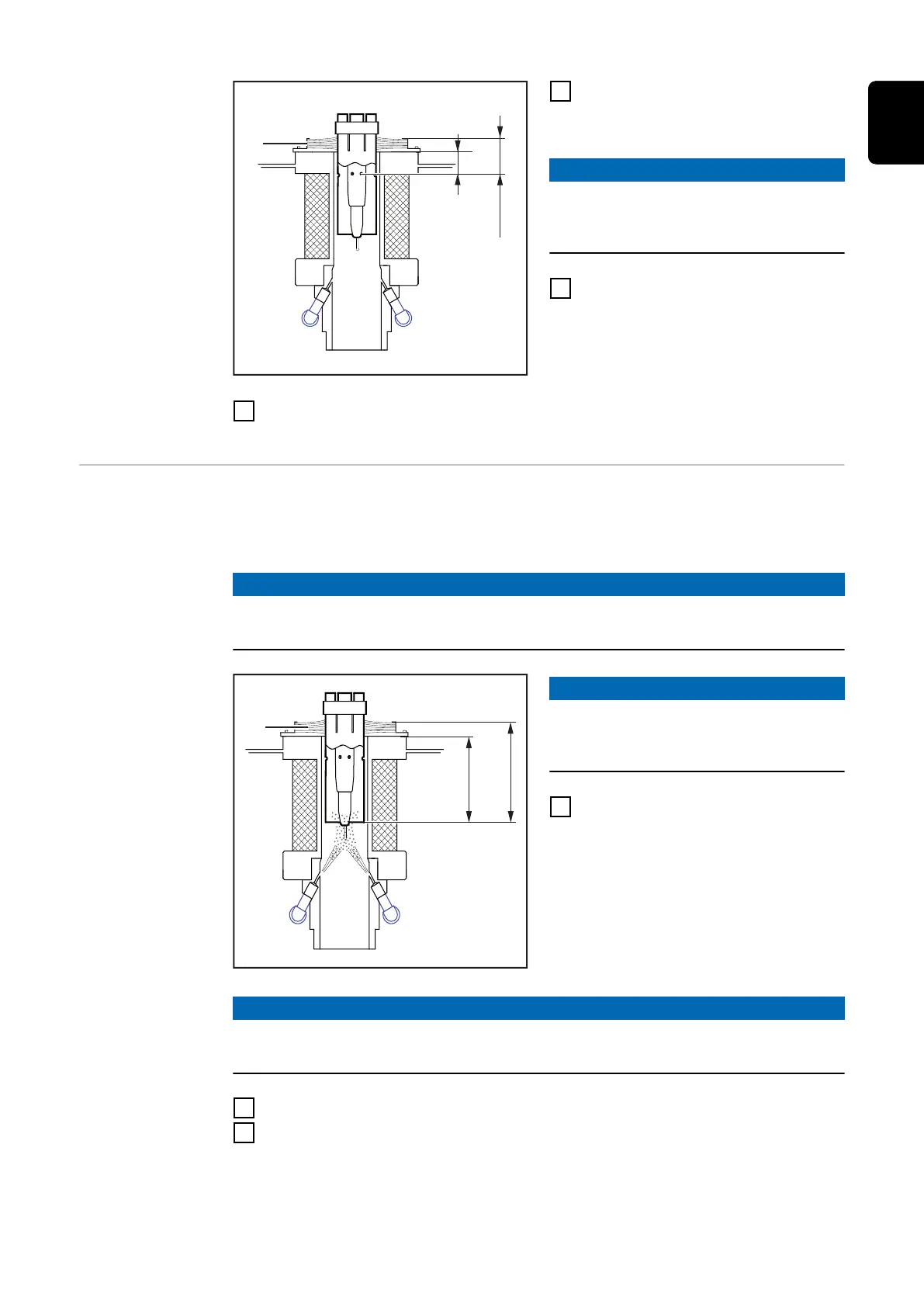

15 mm

(0.59 in.)

25 mm

(0.98 in.)

(1)

1

Position the welding torch approx.

40 mm (1.57 in.) centrally above

the middle of the cleaning opening

NOTE!

If the brush seal (1) is not fitted, note

the changed reference point when po-

sitioning the welding torch.

2

Insert welding torch vertically into

cleaning opening. Immerse the

torch so that the gas nozzle holes

are approx. 25 mm (0.98 in.) inside

the cleaning opening

3

Begin cleaning and hold the welding torch in the cleaning position for approx-

imately 1 second

Spraying parting

agent - detailed

description

Applying parting agent evenly has the following advantages:

-

shorter cleaning time

-

prevents re-soiling

NOTE!

Ensure that the gas nozzle does not touch the housing components of the clean-

ing opening at any time.

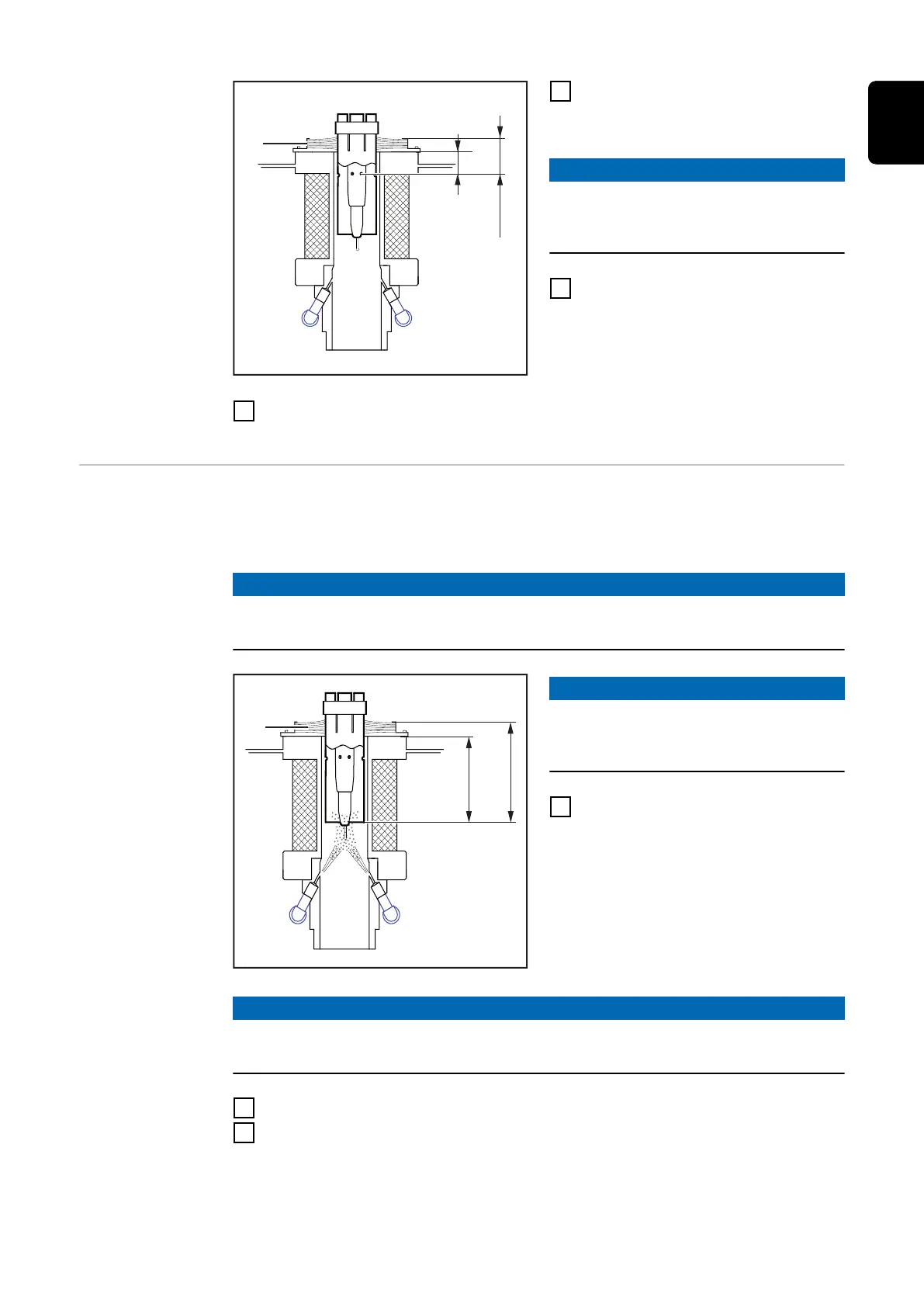

75 mm

(2.95 in.)

65 mm

(2.56 in.)

(1)

NOTE!

If the brush seal (1) is not fitted, note

the changed reference point when po-

sitioning the welding torch.

1

Place the welding torch in the

spray position

-

see figure

NOTE!

During the spraying process, ensure that compressed air is not blown out

through the welding torch.

2

Spray welding torch with parting agent for approximately 0.7 seconds

3

Move the welding torch to the start position above the cleaning opening - ap-

prox. 40 mm (1.57 in.) centrally above the middle of the cleaning opening

-

The cleaning operation is complete and the welding torch is ready for use

again

67

EN

Loading...

Loading...