81

12.4 Tighten Print Head Hot Section

Periodically, especially if you run exotic or extremely high temperature filaments, you may find molten

filament oozing out of your print head’s hot section like lava. Typically this is dark in color, and may

come from the top of the hot block or from directly above the nozzle.

Image TBD

1. Here is how to fix this and get some more life out of your print head.

2. Unload filament if it is in the print head.

3. Remove the print head from the print head assembly, but leave it electrically connect (see

section 12.9).

4. Heat the print head to 290

o

C. Wipe off the ooze when it’s soft enough to wipe.

5. Locate a pair of slip-jaw pliers and a 10mm hex socket.

6. When the head has reached 290, clamp the hot block in the pliers and tighten the nozzle using

the 10mm socket. Tighten to 20-30 in-lb. The printer may throw a heater fault as the head cools

down (because we’re holding it in cold tools); this is ok.

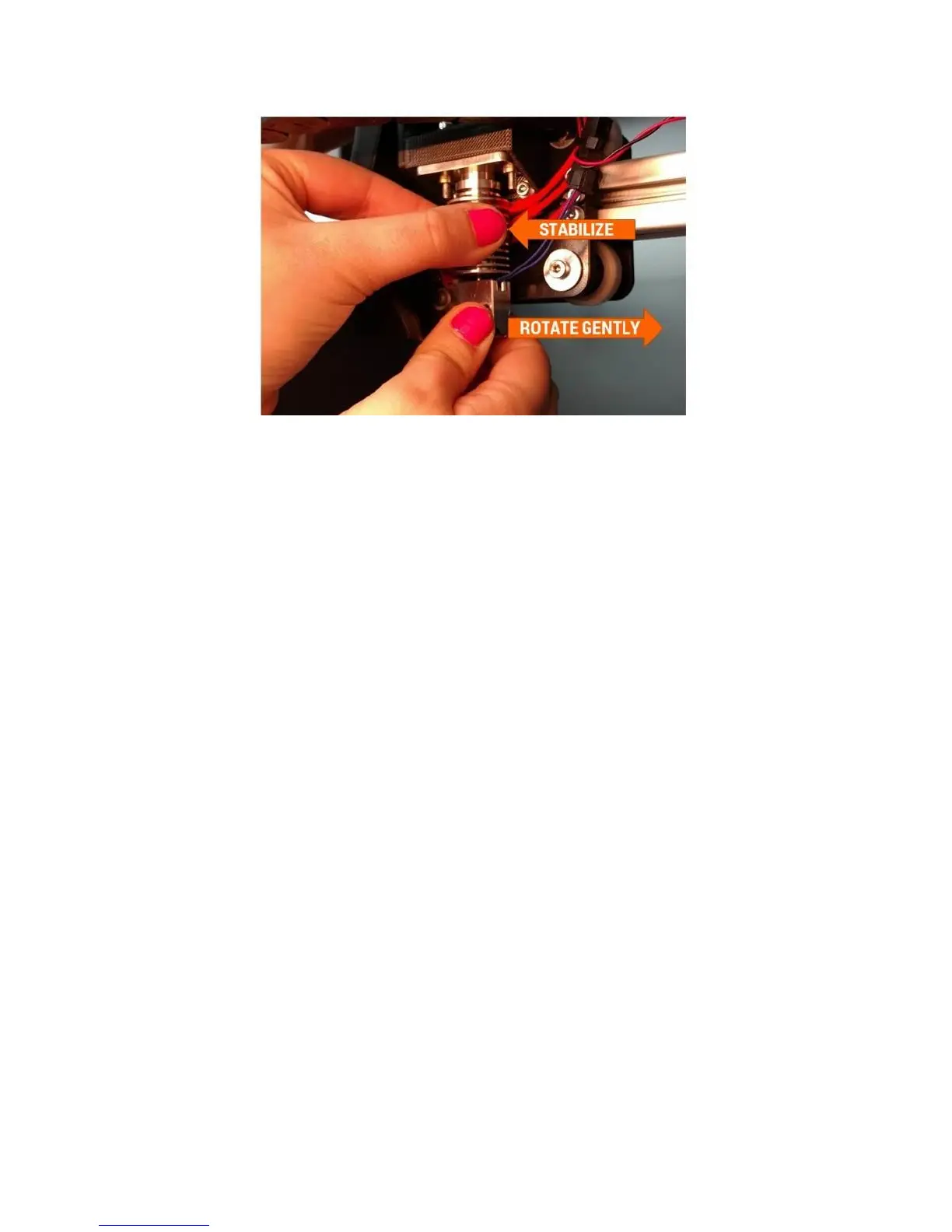

Image TBD

7. Turn off the print head heater. Allow the head to cool.

8. Re-install the print head.

12.5 Inspecting & Cleaning the Extruder

Check the extruder for:

Debris in the feed gear

Slop or lash in the gears

Correct spring preload

Loading...

Loading...