G1000 / GFC 700 System Maintenance Manual - 300/B300 Series King Air Page 4-11

190-00716-01 Revision 4

4.4 Visual Inspection

Perform a visual inspection in accordance with requirements in Table 4-1. Check for corrosion, damage,

or other defects for each of the items listed in Table 4-3 through Table 4-8. Replace any damaged parts

as required. Inspection may require the temporary removal of a unit or units to gain access to connectors.

Follow guidance in Section 6 for equipment removal and replacement. Refer to the Super King Air 300

or B300 Maintenance Manual listed in Table 1-2 for instructions on removing any access panels.

NOTE

It is recommended that the Phase 3 and Phase 4 electrical bonding checks contained in section 4.5 are

conducted after the Phase 3 and 4 visual inspections while access to these zones is still open.

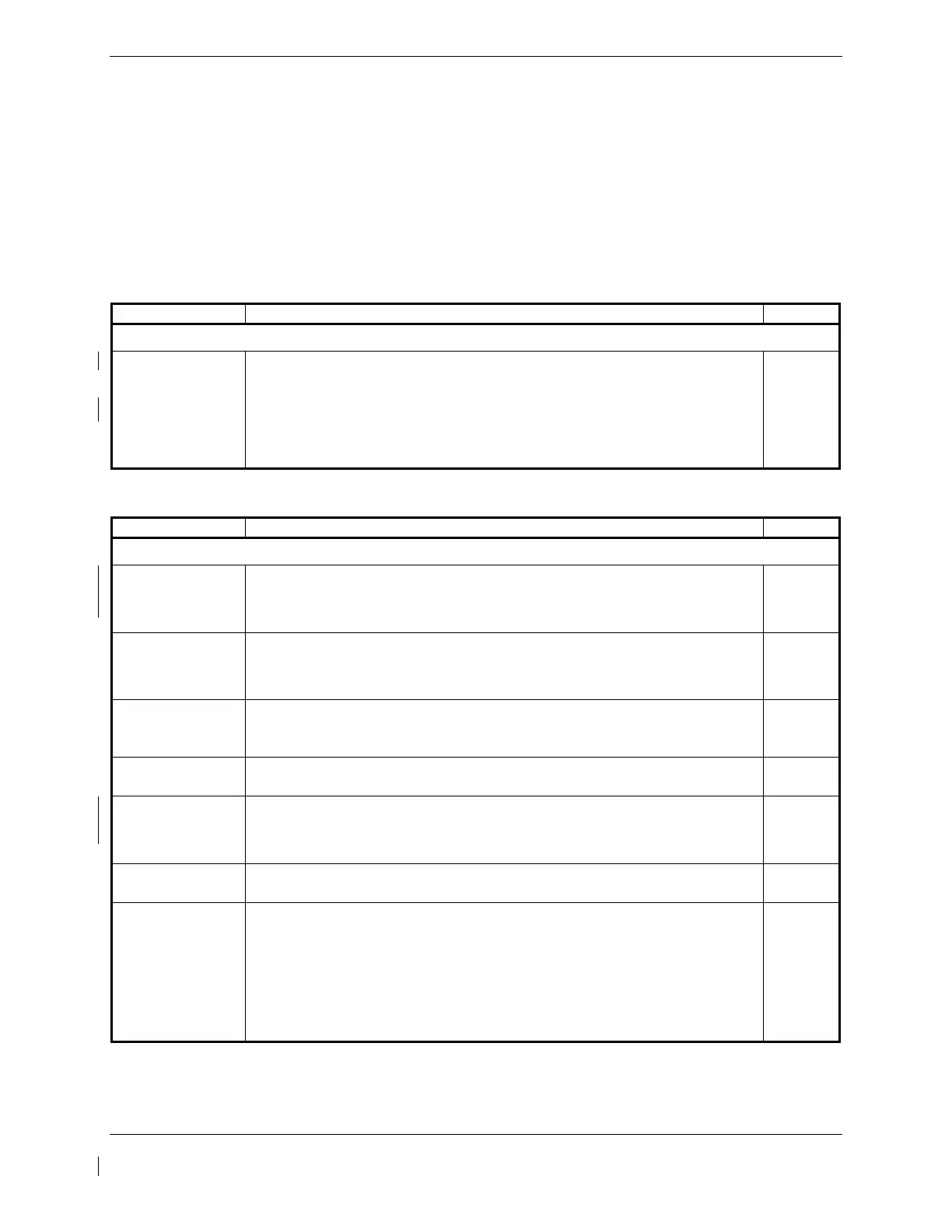

Table 4-3, Nose Section Visual Inspection Procedure

Item Description/Procedure Initials

Gain access via the Radome for the following Inspection:

GWX 68 or GWX 70

a) Inspect the GWX 68 or GWX 70 unit, mount, and connectors for corrosion or other

defects. Check the integrity of the SHIELD BLOCK ground attachments to the

harness connector assembly as well as the integrity of the individual shields and their

attachment.

b) Inspect wire harness for chafing, damage, proper routing of wire bundles and security

of attachment in accordance with AC 43.13-1B, Chapter 11, Section 8, Paragraph

11-96 and the Nose Wire Harness Routing drawing, listed in Table 1-2

.

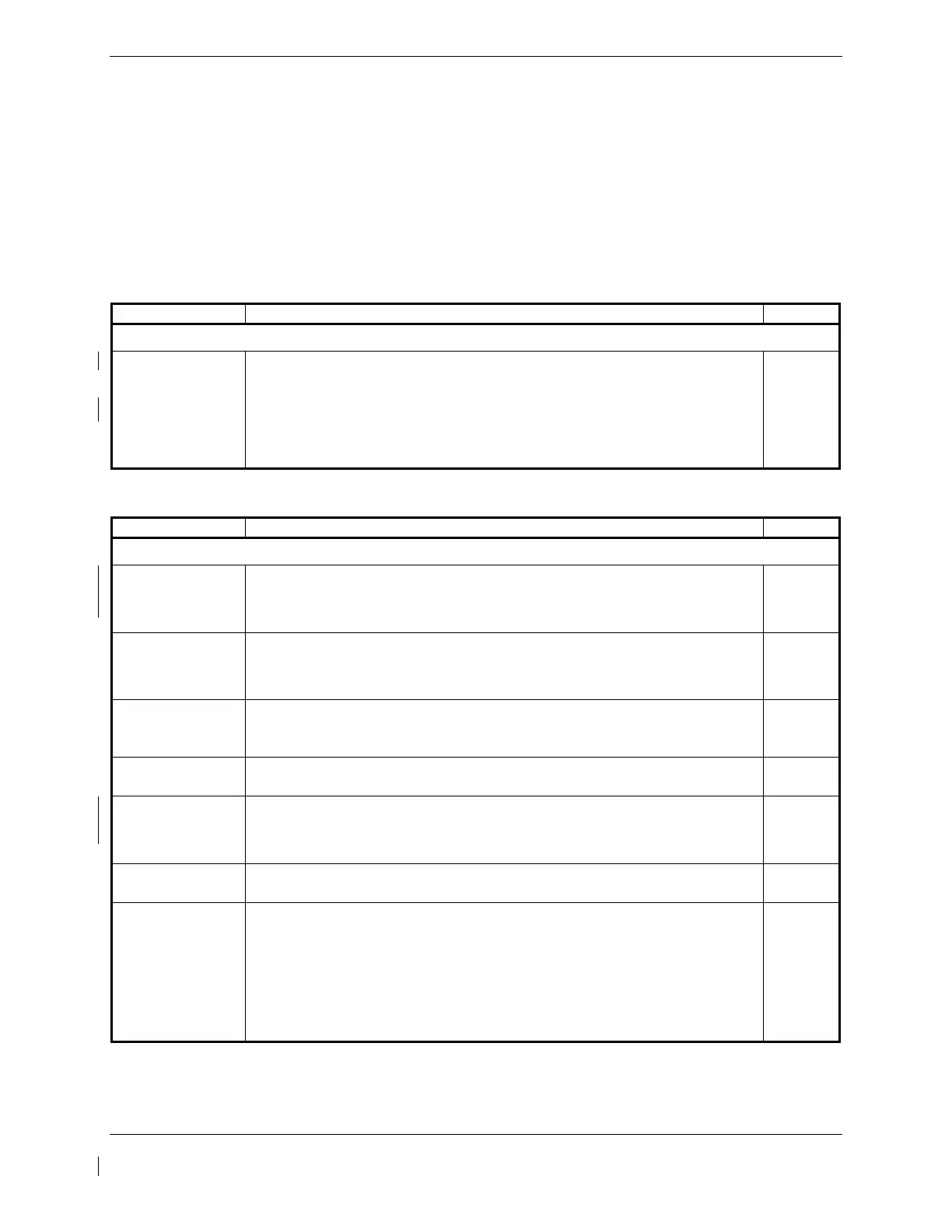

Table 4-4, Nose Avionics Compartment Visual Inspection Procedure

Item Description/Procedure Initials

Gain access via the Nose Equipment Compartment access panel for the following Inspection:

GRS 77 or GRS

7800 (Qty 2)

a) Inspect the GRS 77 or GRS 7800 units, racks, and connectors for corrosion or other

defects. Check the integrity of the SHIELD BLOCK ground attachments to the

harness connector assembly as well as the integrity of the individual shields and their

attachment.

GIA 63W (Qty 2)

a) Inspect the GIA 63W units, racks, and connectors for corrosion or other defects.

Check the integrity of the SHIELD BLOCK ground attachments to the harness

connector assembly as well as the integrity of the individual shields and their

attachment.

Standby Battery

a) Inspect the standby battery, rack and connectors for corrosion, or other defaults.

b) Inspect the standby battery fuses and associated bracket for corrosion or other

defects.

GIA Cooling Fan

(Qty 2)

a) Inspect remote cooling fans and hoses for dirt accumulation and other damage.

Remove excess dirt as required.

GTS 820/850 Traffic

or GTS Traffic

Processor

(option)

a) Inspect the GTS 820/850 or GTS Traffic Processor unit (if installed), rack and

connectors for corrosion or other defects. Check the integrity of the shield block

ground attachments to the harness connector assembly as well as the integrity of the

individual shields and their attachment.

LMD Rack and

Modules

a) Inspect the LMD rack, modules, and terminations for corrosion or other defects.

Nose Wiring harness

a) Inspect bulkhead connectors for security of attachment, corrosion or other defects.

b) Inspect wire and coax for chafing, damage, proper routing of wire bundles and

security of attachment in accordance with AC 43.13-1B, Chapter 11, Section 8,

Paragraph 11-96 and the Nose Wire Harness Routing drawing, listed in Table 1-2. .

Pay particular attention to possible areas of chaffing such as the middle shelf feed-

through hole, wheel well protrusion etc.

c) Inspect Ground blocks for security of attachment, corrosion or other defects.

d) Ensure all connectors are securely fastened.

Loading...

Loading...