Use the zero-servo gain parameter 11-49 to adjust the holding torque in zero-servo operation. If the set value

is increased, the holding torque will increase but instability may occur. Do not use the zero-servo function at

100% of the inverter rated current as this may cause the inverter to overheat (OH1). Zero-servo may perma-

nently be used to maintain 50 – 60% of the inverter rated current. Increase inverter rating if more is required.

11-50: Zero-servo count

Zero servo count is used to specify the zero-servo position offset from the zero-servo start position used for

zero-servo completion.

11-51: Operation selection of zero-speed braking

In V/f control mode, the DC braking operation (without PG feedback) can be used to the motor shaft.

Set 11-51 to select zero-speed braking operation to 1 to enable this function.

To use DC braking operation set parameter 00-02 (operation command selection) to 1 and parameter 00-05

(frequency reference selection) to 1, the operation command and frequency reference are now set for external

control. When the frequency reference is 0V (or less than 4mA), and the operation command is turned on, the

zero-speed ‘DC’ braking operation is activated and holding torque is generated using DC braking.

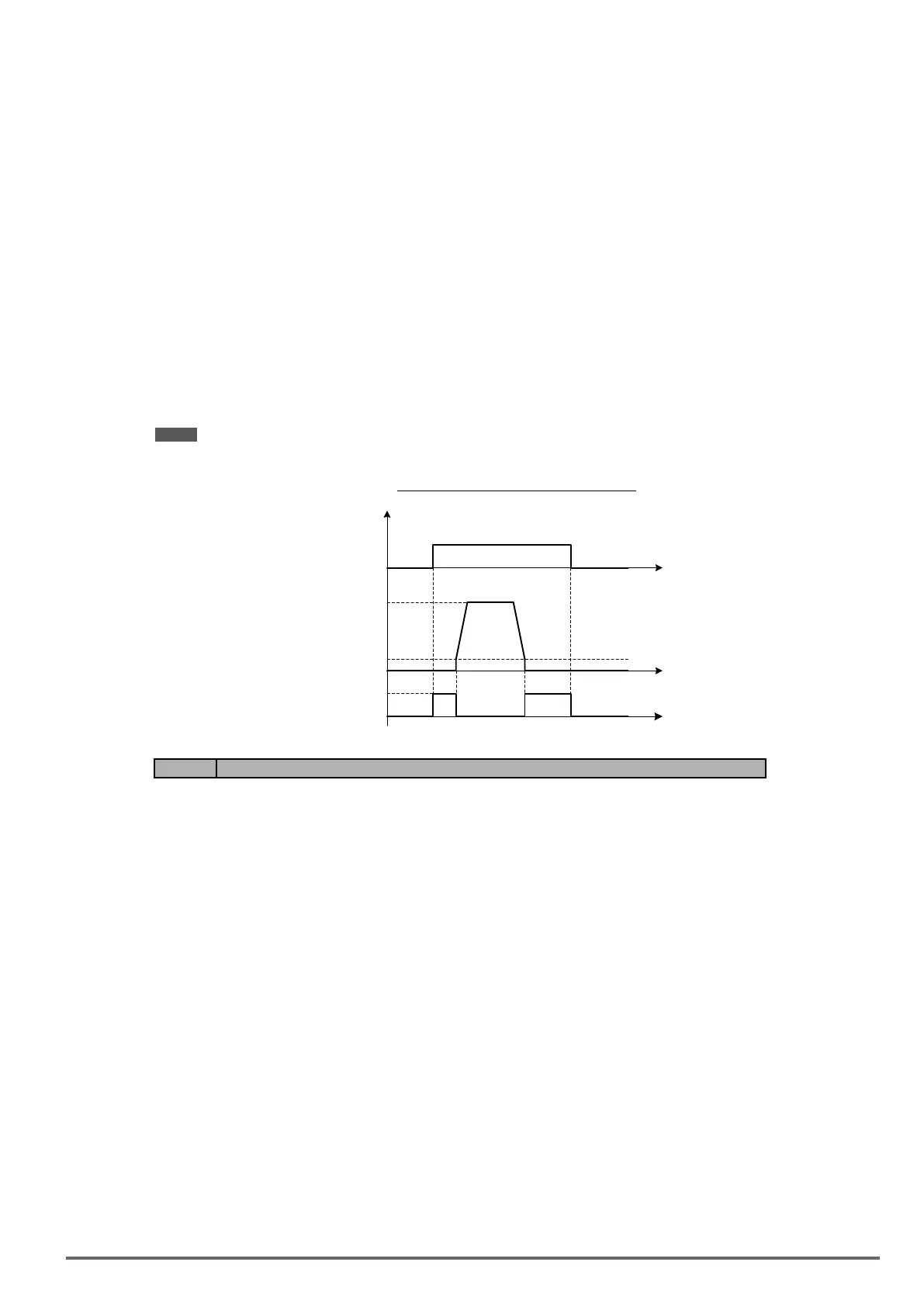

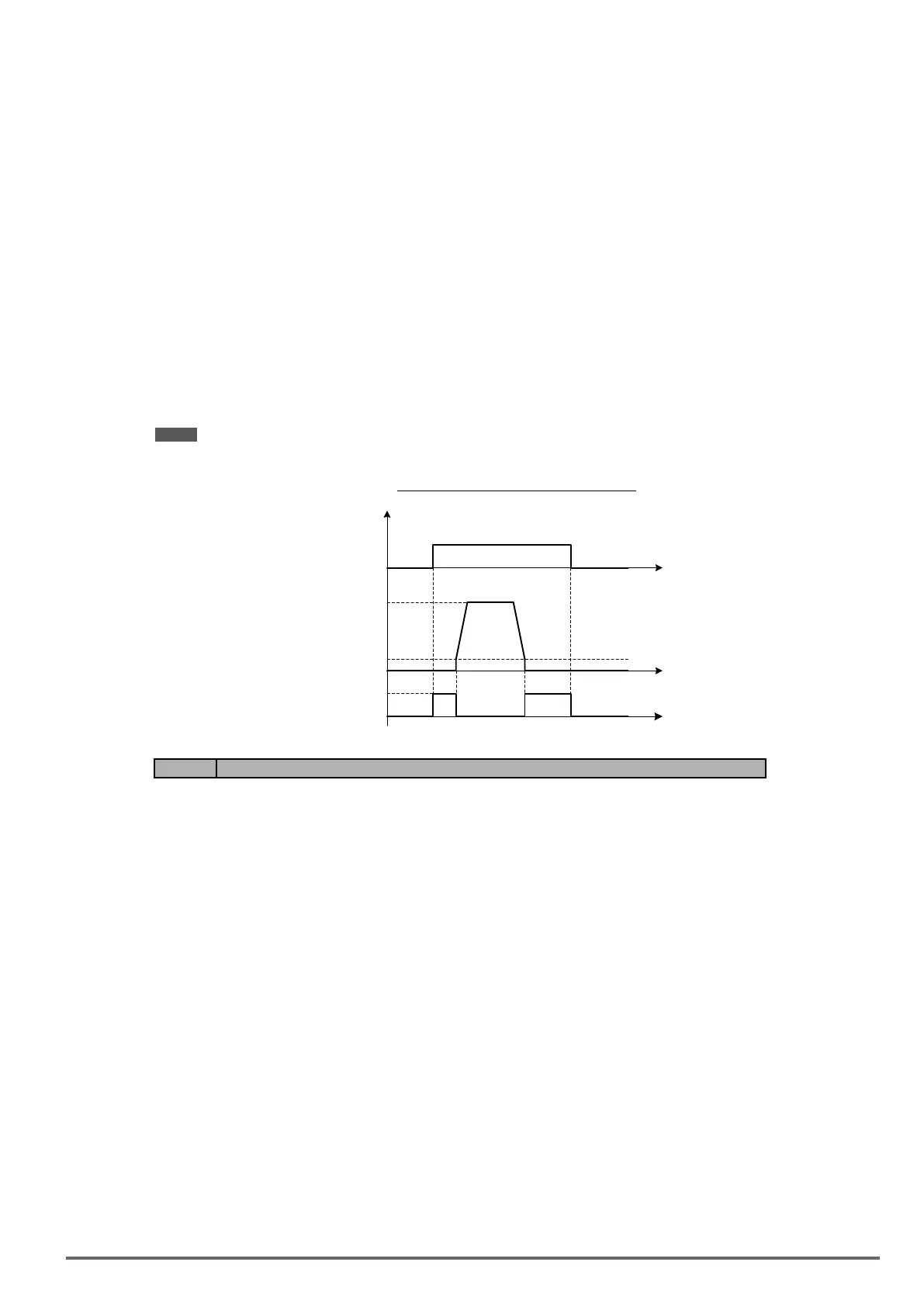

Refer to Figure 4.3.97 for more information on zero-speed DC braking operation.

Note: DC braking 07-07 is limited to 20% of the inverter rated current.

Figure4.4.97Zero-speedbrakingoperation

Run command

Frequency

Reference

DC Injection Braking

( 20% max. )

Zero speed level

(THe larger of 01-08 or 07-06)

t

t

t

Code Parameter Name / Range

11-52 Droop control level

0.0~100.0%

11-53 Droop control delay

0.01~2.00 s

Droop control is used for load balancing when using two standard AC motors to drive the load in applications

such as cranes and conveyors. When droop control is active the inverter reduces the speed when the torque

reference rises and increases the speed when the torque reference drops.

(a) Load balancing using the standard AC motors.

The load torque of motor A, TA > The load torque of motor B ,TB.

(b) Load balancing using high slippage AC motors.

The load torque of motor A ,TA is very close to the load torque of motor B ,TB.

VDI100 • Instruction manual 235

Loading...

Loading...