- 114 -

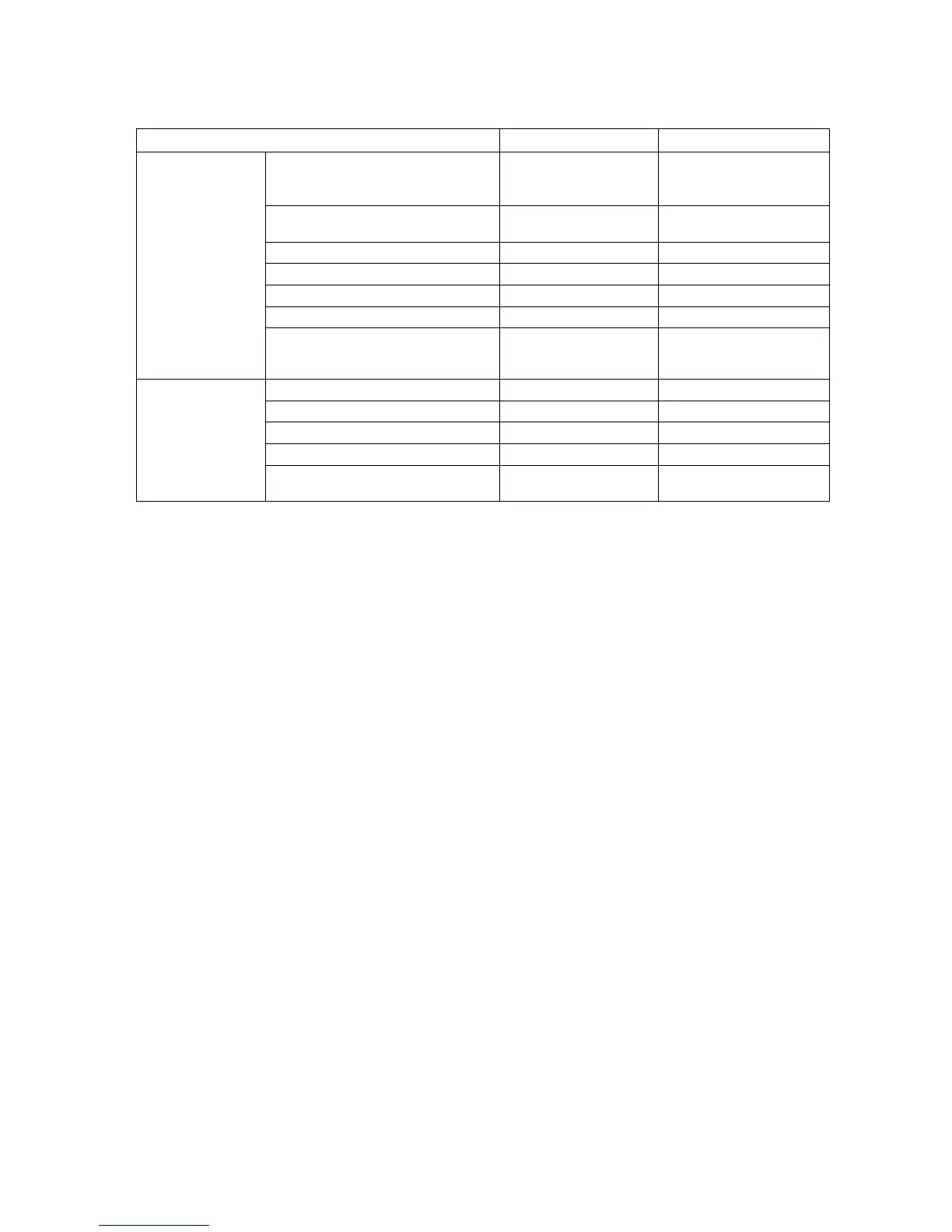

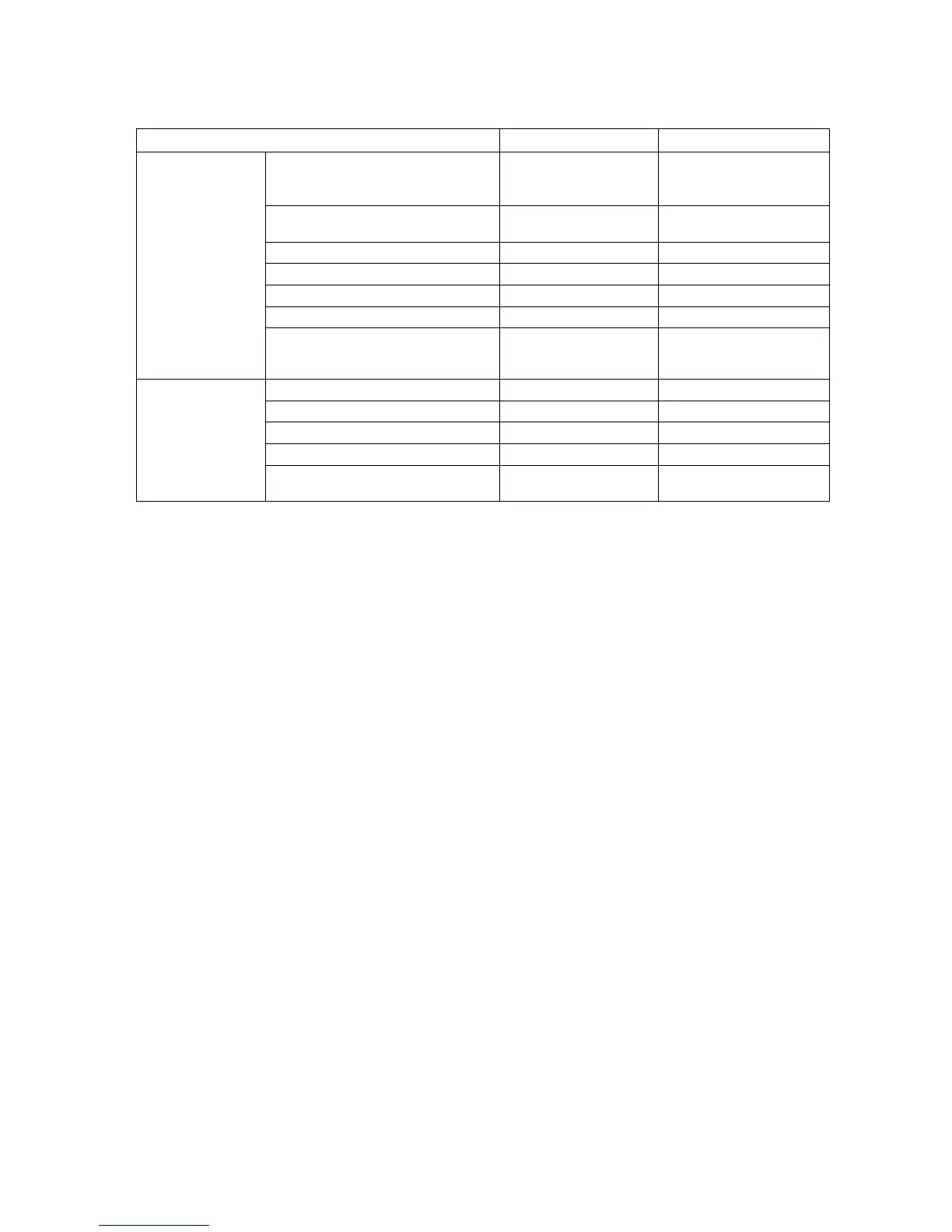

Table of standard values of baseline projects and allowable limit Unit: mm

Item Standard Allowable limit

Bent axle

connecting rod

assembly, clutch

Clearance between the left and the

right of the big end of the

connecting rod

0.1-0.35 0.5

Connecting rod big end radial

clearance

0.008-0.018 -

Jump - 0.03

Thickness of friction plate 2.8-2.9 2.5

Flatness of running friction plate 0.04 0.2

Length of pressure spring 30.4-31.6 29.7

Thickness of surface needle roller 1.88-2 1.8

Gearshift

mechanism

Outer diameter of shifting fork axis 9.98-9.995 9.96

Diameter of bore of shifting fork 10-10.018 10.05

Thickness of shifting fork 4.8-4.9 4.6

Outer diameter of gearshift hub 41.8-42 41.75

Width of gearshift hub locked

groove

5.45-5.55 5.7

13.2 Fault Diagnosis

Low compression pressure

Crankcase air leakage

Engine overheat

Clutch clipping

Poor lubrication

Failure in gear

Gear shift fork broken or deformation

Shifting fork guide pin broken

Wheel gear convex claw worn

Auto-off gear

The joint claw is worn with the edge into a fillet.

Force of return spring of the speed shifting mechanism is weakened.

The spline tooth of spline shaft and the spline groove of sliding gear are worn, resulting a greater axial force in

the gear while working.

Gearshift hub and shifting fork are worn.

Abnormal sound in the crankcase

There are parts scattered or broken inside the crankcase

Engine stalling

Clutch is stuck

Shifting difficulty

Separation between the clutches is not complete

Poor returning spring of the clutch

Locked grove of the gearshift hub worn

Loading...

Loading...