- 71 -

VI Ignition System

Preparatory data ----------------6.1 Ignition coil

------------6.5

Fault diagnosis -----------------6.2 Trigger

-----------------6.6

Ignition system inspection ---- 6.3 Charging

coil---------- 6.7

CDI assembly ------------------6.4

6.1 Preparatory Data

Precautions on operation

1. Ignition system inspection: please perform inspection in the sequence listed in the fault diagnosis table.

2. Ignition system uses electronic-type automatic timing device, which is solidified in the CDI assembly, so it

is unnecessary to adjust the ignition time.

3. Ignition system inspection: please perform inspection in accordance with the sequence listed in the fault

diagnosis table.

4. Ignition system CDI shall not be dropped and hung, or heavily knocked (this is also the main reason for its

failure). Pay special attention to this while removing it.

5. Most of the ignition system problem due to poor contact of sockets. Please check first if parts of the

connector are well contacted.

6. Check if heat value of spark plug is proper. Improper spark plug may result in unsmooth engine running or

burn of spark plug.

7. The maximum voltage is taken to introduce inspection items in this Part. Inspection methods for impedance

value of ignition coil are also recorded and judged.

8. Check ignition switch according to the continuity test table.

9. Remove alternator and stator on operation instructions.

Preparatory data

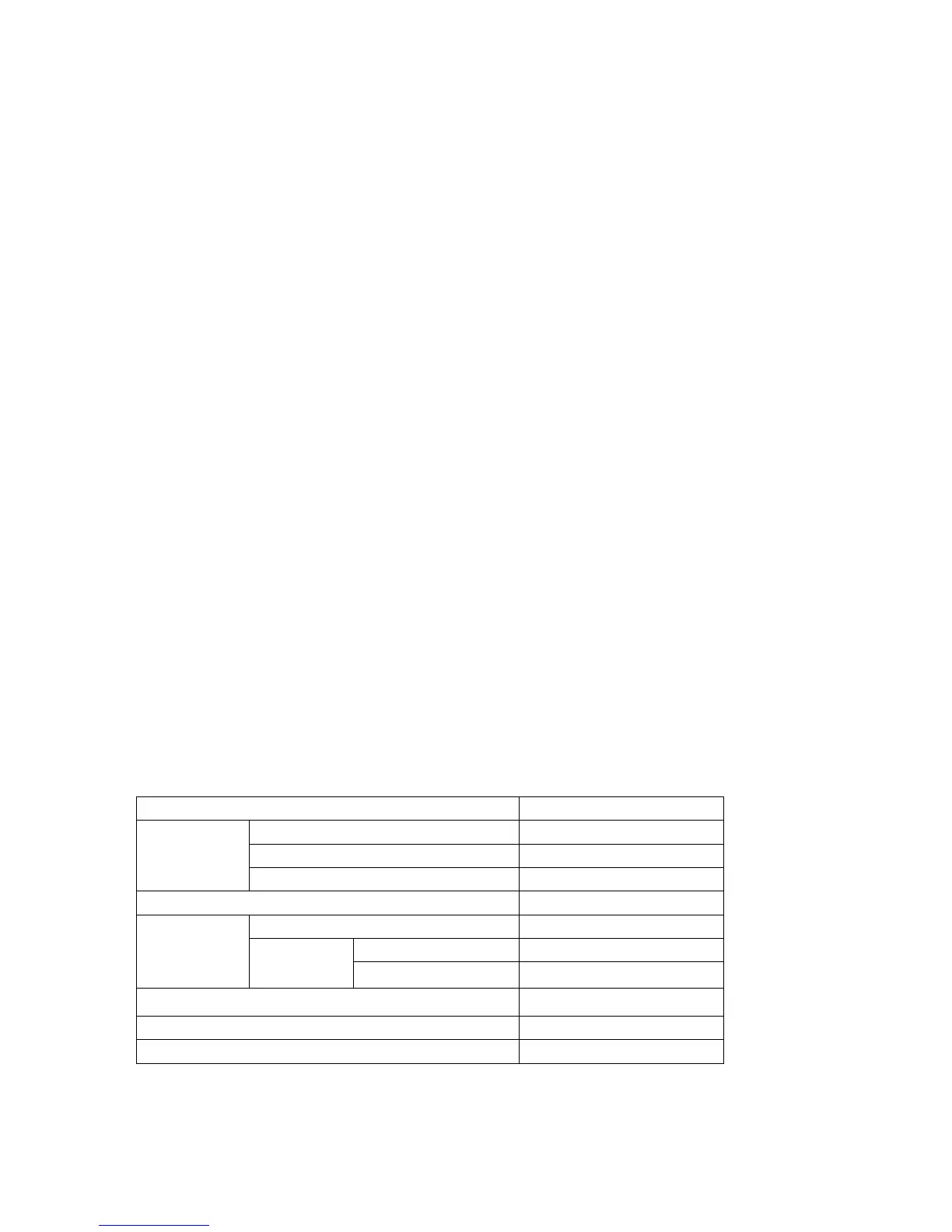

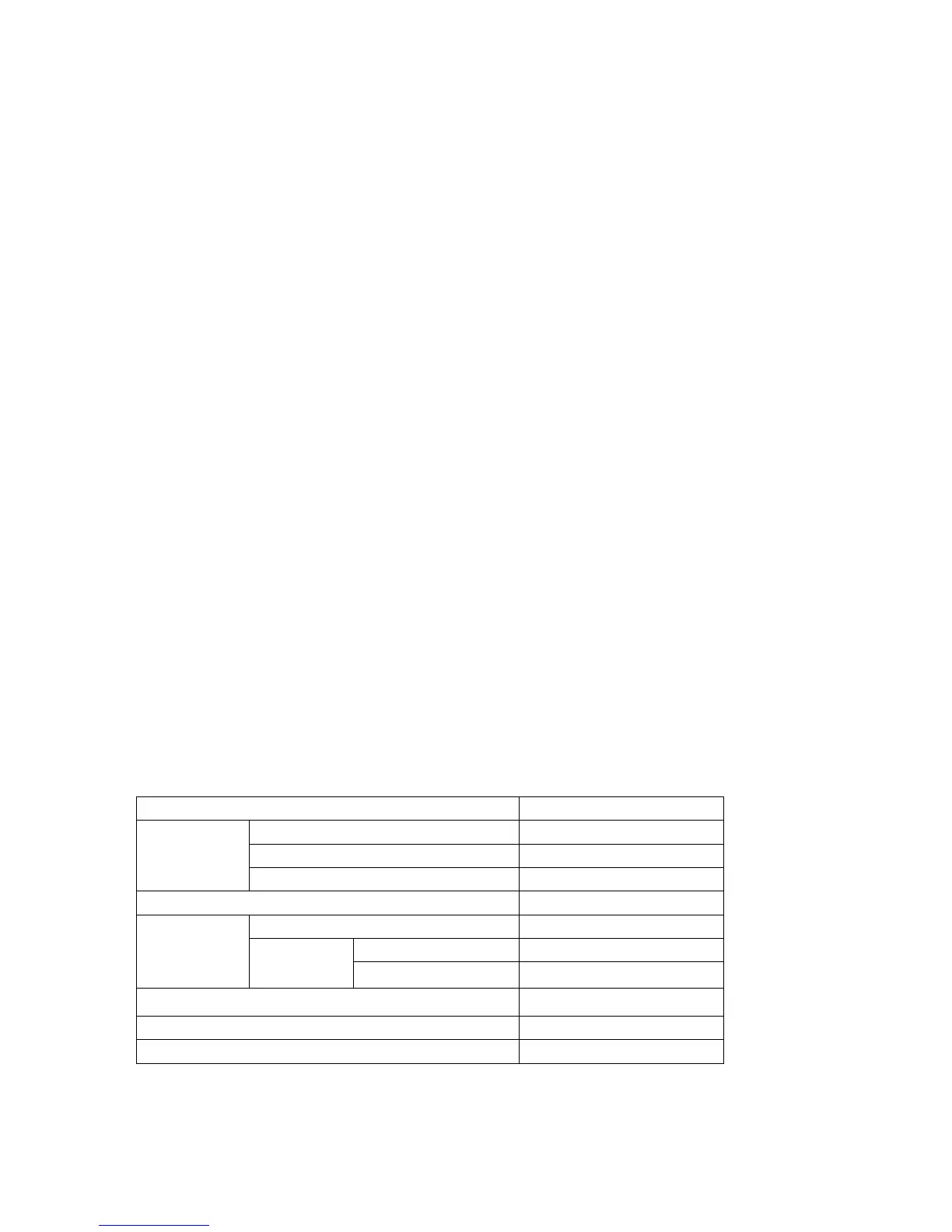

Item Standard Value

Recommending

spark plug

Standard

C5HSA(NGK)

Hot type C6HSA(NGK)

Cold type C7HSA(NGK)

Spark plug gap 0.5-0.7mm

Ignition coil

impedance

value (20)

Primary coil

0.4Ω(+/-)10%

Secondary

coil

With spark plug cap 8-11KΩ

Without spark plug cap

4.5-5.5KΩ

Impedance value of trigger (20) 100-200Ω

Ignition coil primary peak voltage 95-400V

Trigger voltage ABOVE 1.7V

Tools

Loading...

Loading...