34

Instruction manual

Electric Actuators Type EA15-250

7.3 Troubleshooting

NOTE!

Repair the fault either while the supply voltage is still applied or when the actuator is briefly disconnected from the main power (not

eective in cycle monitoring).

1. Check the cause of fault. To do so, open the cover of the actuator, if necessary.

2. In order to remove the fault, press the SET button on the base board, in order to acknowledge the error, or disconnect the actua-

tor from the mains.

3. Perform troubleshooting in accordance with the table.

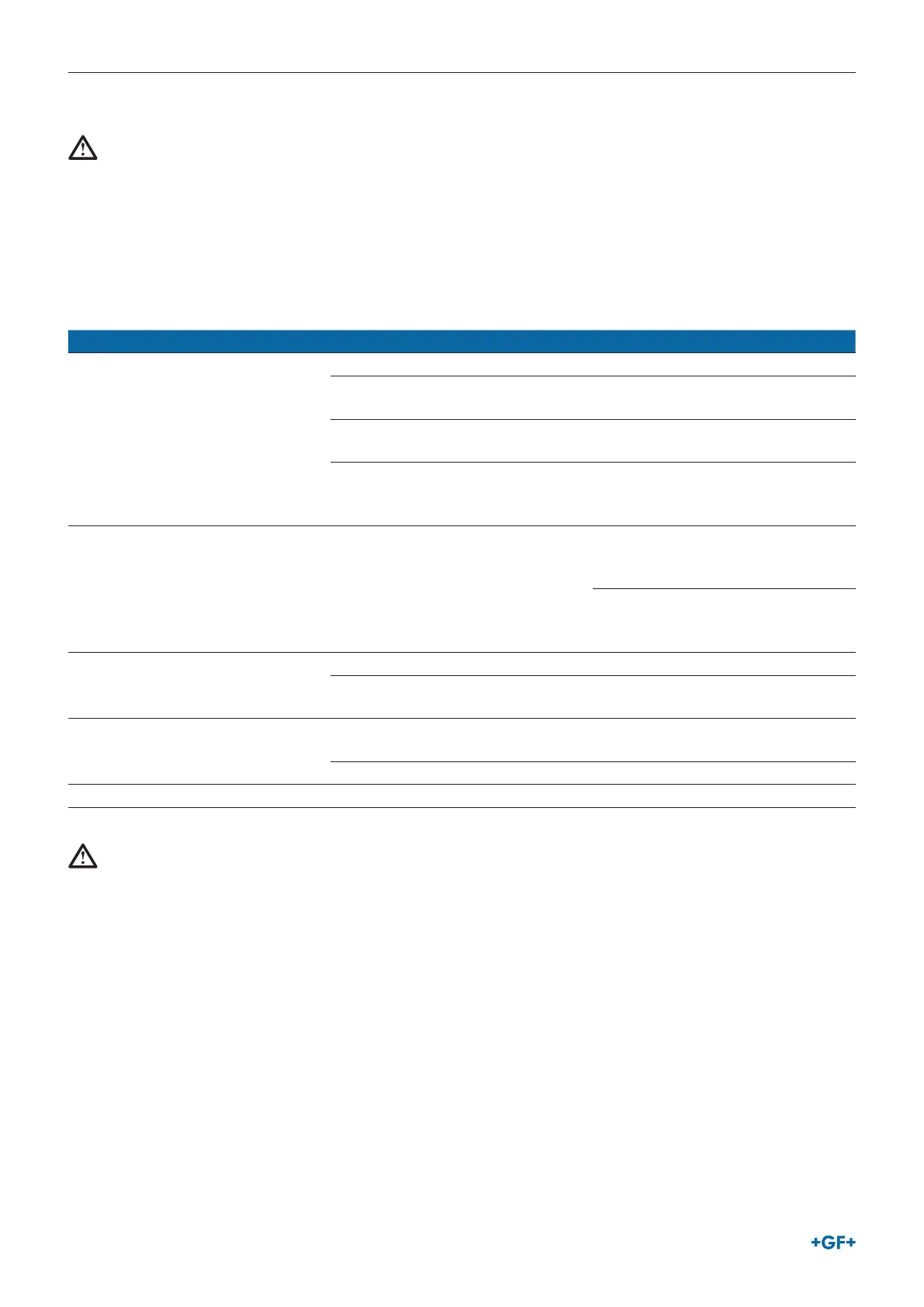

Fault Possible cause Remedy

Actuator does not react No power available ► Check voltage source.

Internal wiring error ► Correct the wiring of the actuator,

see Chapter “Installation»

End positions not correctly set ► Adjust the end positions; see Chapter

“Adjusting end positions”.

Motor blocked ► Use emergency manual override; see

Chapter “Insert the emergency

manual override hand crank”.

Actuator only runs in one direction

Position sensor defective

► Use emergency manual override; see

Chapter “Insert the emergency

manual override hand crank”.

► Perform a learning run as described

in chapter “Teaching of the position

sensor”.

Overload protection is activated Valve dirty/jammed ► Clean the valve, see valve manual.

Ambient temperature too high ► If possible, reduce ambient tempera-

ture.

Valve does not fully close or open End positions not adjusted ► Adjust the end positions, see Chapter

“Adjusting end positions”.

Valve dirty/jammed ► Clean the valve, see valve manual.

Valve does not close or open correctly Valve stem twisted ► Replace valve stem

NOTE!

If an end position is not reached, the actuator automatically switches o after 2 min. and displays an error message.

Loading...

Loading...