29

333/334 HPLC PUMPS | USER’S GUIDE

HYDRAULIC CONNECTIONS

Solvent Inlet Lines

For each solvent pump, the standard accessory package contains an inlet line fitted with a

20µm inlet filter.

Connect the inlet line to the inlet tee. The filter goes in the solvent bottle.

Air entering the hydraulic circuit would adversely affect the flow rate. Make sure that all

connectors are correctly seated and properly tightened.

To ensure the connectors are seated and properly tightened:

1. Remove the plastic plug from the inlet of each head.

2. Check that the reverse ferrule is correctly seated at the end of the tubing.

3. Connect the solvent inlet line to the inlet tee.

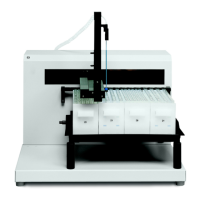

When screwing or unscrewing the white

connector, secure the tubing with one

hand and slide the connector down.

Make sure the ferrule touches the female

port while sliding the connector down to

prevent the line from twisting.

Figure 21

Ferrule and Connector Close Up

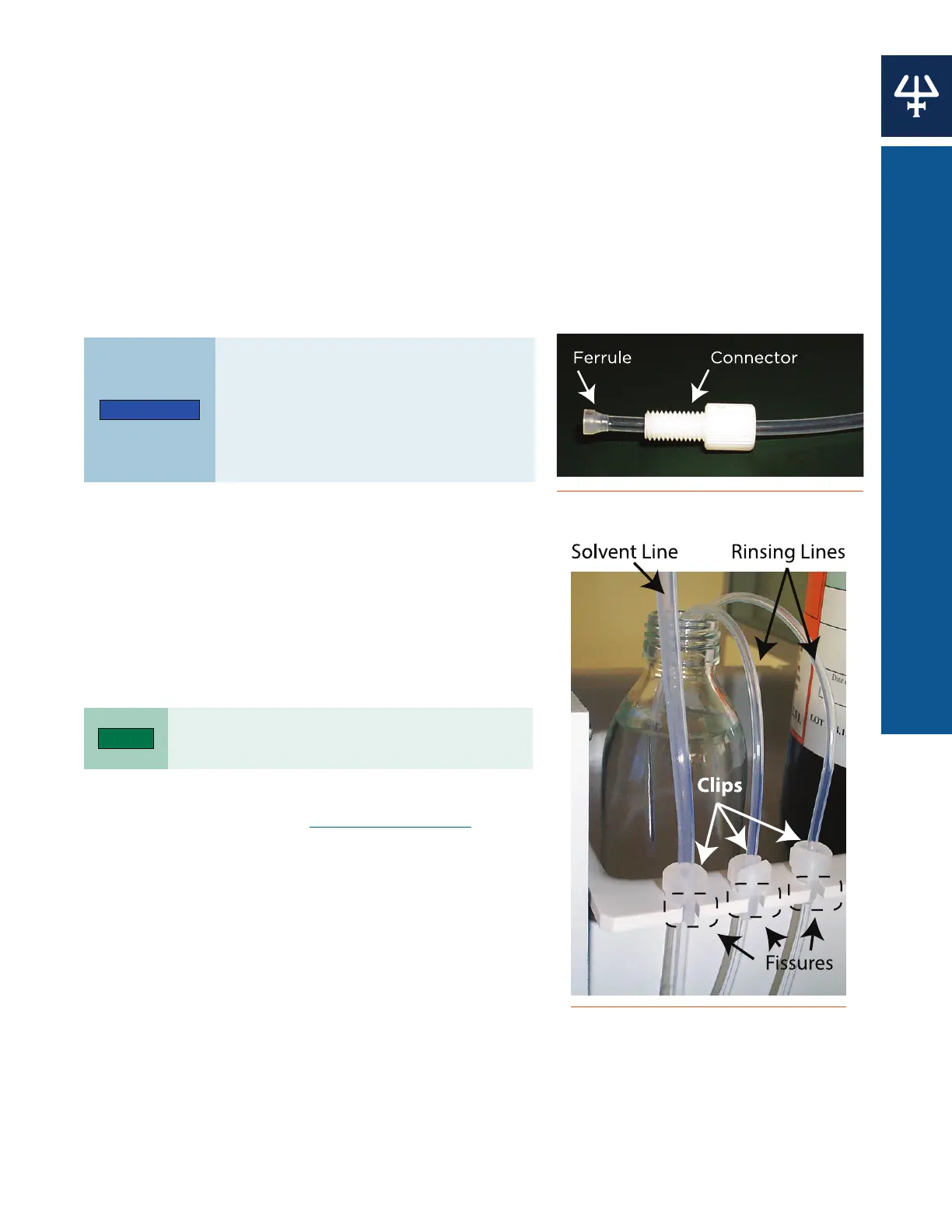

Figure 22

Solvent clips in Fissures

4. Check that the connectors are tight enough to

prevent air from entering the hydraulic lines.

5. Thread the solvent line through the port on the door

before placing the inlet filter in the appropriate solvent

bottle.

6. Clip the solvent lines to the tray. Push the tubing into the

fissure on the clip before placing it in the appropriate

slot on the tray.

Because of the larger diameter tubing, a dierent

clip is supplied for the rinsing line.

7. Prime the solvent lines prior to operation. Follow the

instructions provided in Priming on page 34 for both

TRILUTION LC and manual control.

Loading...

Loading...