36

OPERATION | 333/334 HPLC PUMPS

PRIMING

Piston Rinsing Procedure

PLUMBING SETUP

1. Fill the glass bottle (part number 54350403) with

distilled water and push the open end of each rinsing

line through the bottle’s pierced cap, to between 1 to

2cm of the bottom.

2. Clip the rinsing lines to the tray. Each line is first attached

to a clip by pushing it gently into the fissure, and then

the clip is pushed into a slot on the tray.

PRIMING OPERATION

1. Ensure that each purge line is closed (turn each

connector fully counterclockwise until finger tight), then

press Manual, Prime, Start (or pump at an appropriate

flow rate—the maximum flow rate, for example). After

about 20seconds, water should have sufficiently filled

the rinsing line, even though some air is also present.

2. Stop the pump and then undo both purge line connectors.

Water will run from each purge line into the drip tray;

the rinsing lines and rinsing chambers will fill with water.

When you see bubble-free water in the rinsing lines,

and that air is no longer exiting from the head via the

purge lines, close both purge lines. In use, water from

the small bottle rinses the piston and although it is a

closed circuit, you may need to change the water from

time to time and also repeat this procedure.

To get the initial flow of water to reach the pump head, it may be necessary to use a priming

syringe (part number 36460058) to pull excess air from the rinse line. Opening and closing the

purge line connectors can also encourage initial rinse water flow.

Over time the buer concentrate will dilute into the water bottle via entropy and laminar

flow. To prevent sediment build-up in the piston chamber, change the water and clean the

bottle.

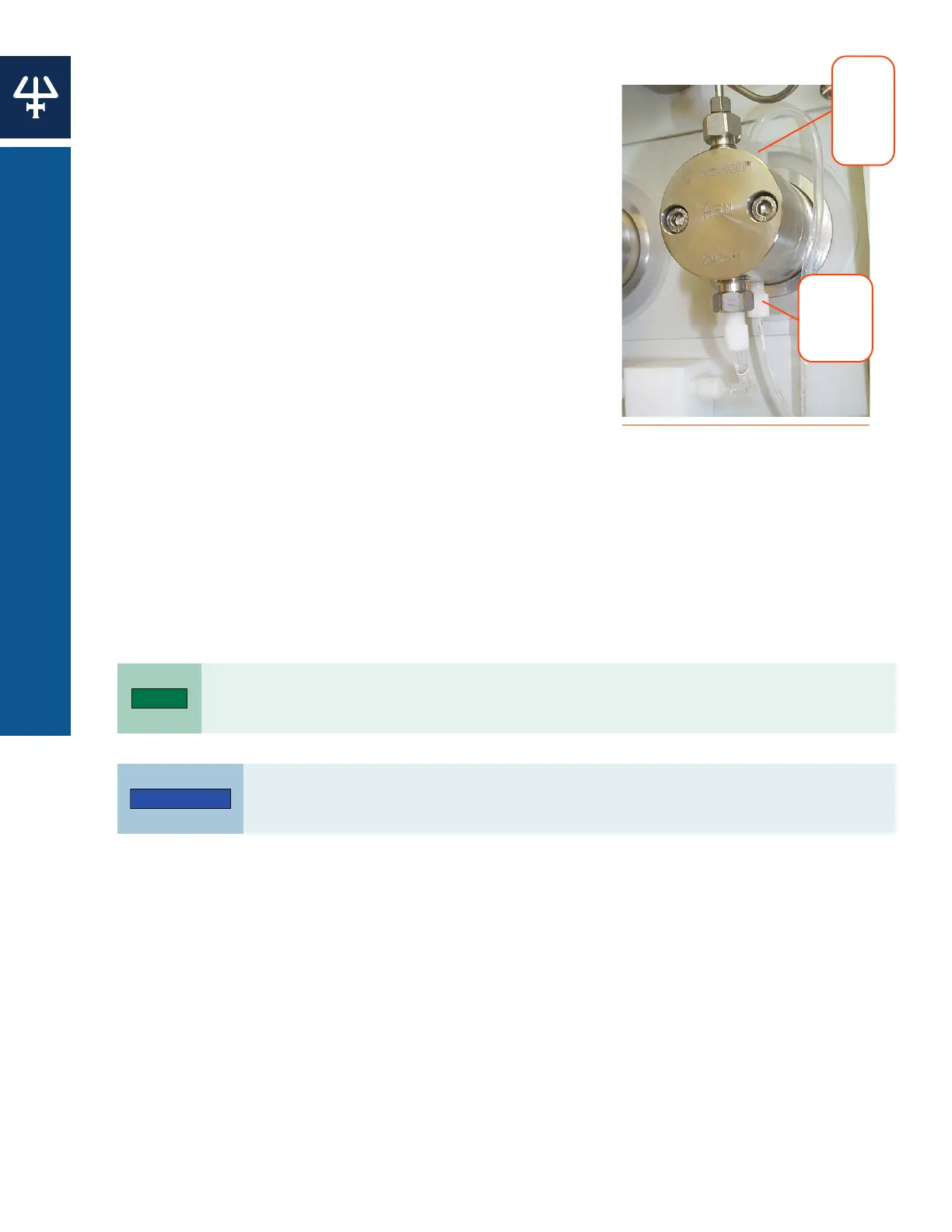

Figure 28

Close Up of Piston Rinse Lines

Rinsing

Line

from

Bottle

Purge

Line

to

Drip

Tray

Loading...

Loading...