15

Checks to perform before installation

Check on the technical plate on the left-hand side of the oven that the

appliance has been tested and approved for the type of gas that the

user's premises (Fig. 12, ref. A)�

Check, using the data on the technical plate (Fig. 12), to make sure that

thepressurereducercapacityissufcientfortheappliancesupply. Donot

install section reducers between the reducer and the appliance�

It is recommended to install a gas

lter upstream from the pressure

regulator in order to ensure optimal

operation of the oven�

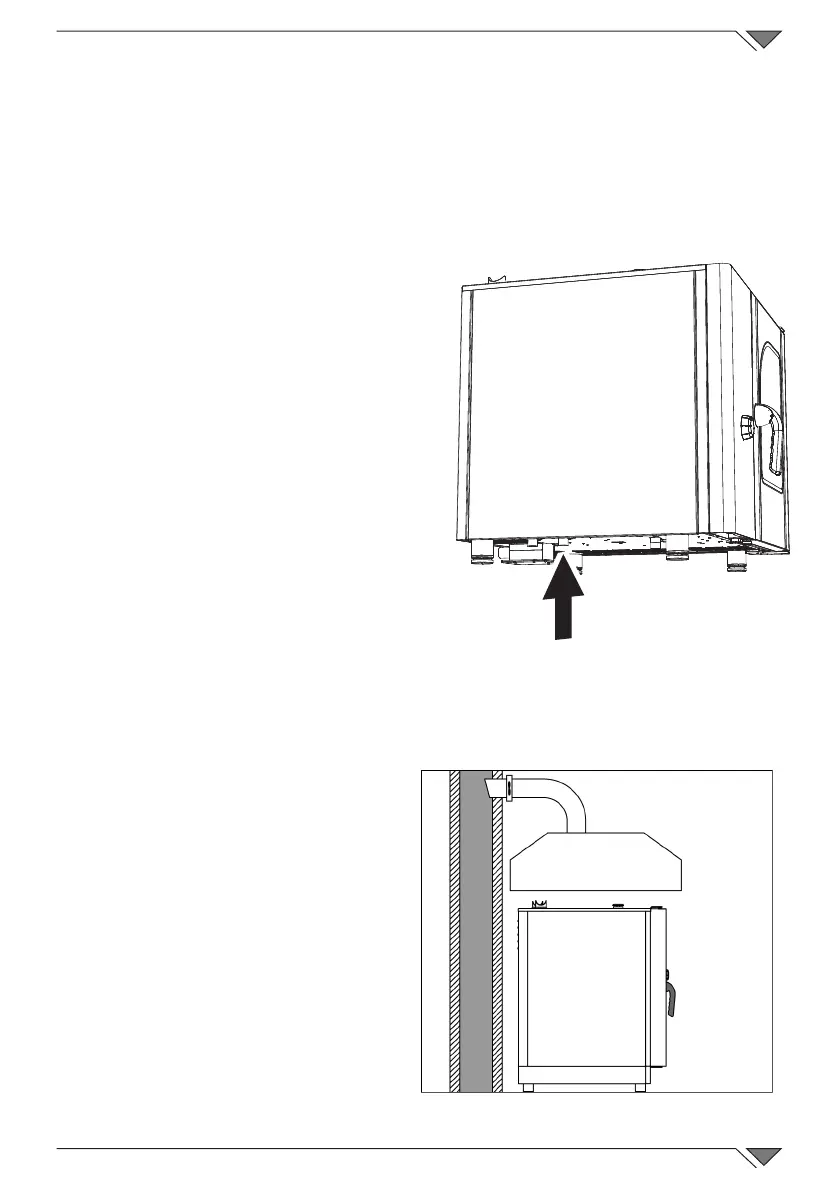

Connect the oven to the gas supply

plant via a tube with diameter of 3/4” and

internal section no smaller than 20 mm

(Fig. 13)� Envision cocks or drain valves

with an internal diameter no smaller than

thettingtubementionedabove.

After connecting the pipe, make sure that

the joints and couplings have no leaks� To

dothis,usesoapywaterorspecicfoamy

product to identify the leak�

It is good practice to have the periodic

maintenance of the gas ovens performed

every year by an authorised technician;

onthisoccasiontheuegaseswillbeanalysedandthe heat output will be

checked�

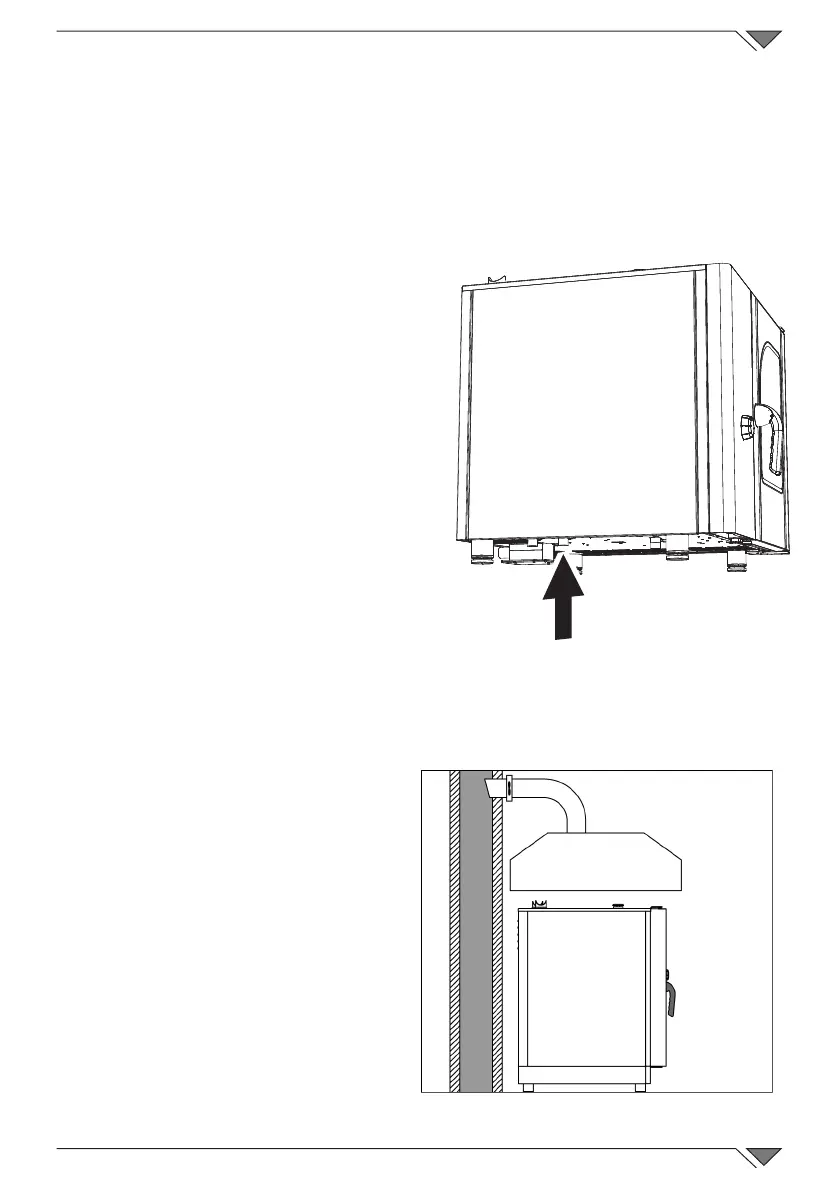

1.8 Smoke exhaust

In compliance with the installation

regulations, the ovens must be

used in premises suitable for the

evacuation of combustion products�

The oven drain can be connected

via a forced evacuation system,

such as a hood with mechanical

extractor (Fig. 14)� In this case,

the gas supply to the appliance

must be controlled directly by this

system and must cut-off whenever

the suction ow rate drops below

Fig. 13

Fig. 14

Loading...

Loading...