14

1.7 Connecting the gas

(gas ovens only)

Nota bene:

The oven is calibrated originally

for operation with the type of gas

speciedonplacingtheorder.

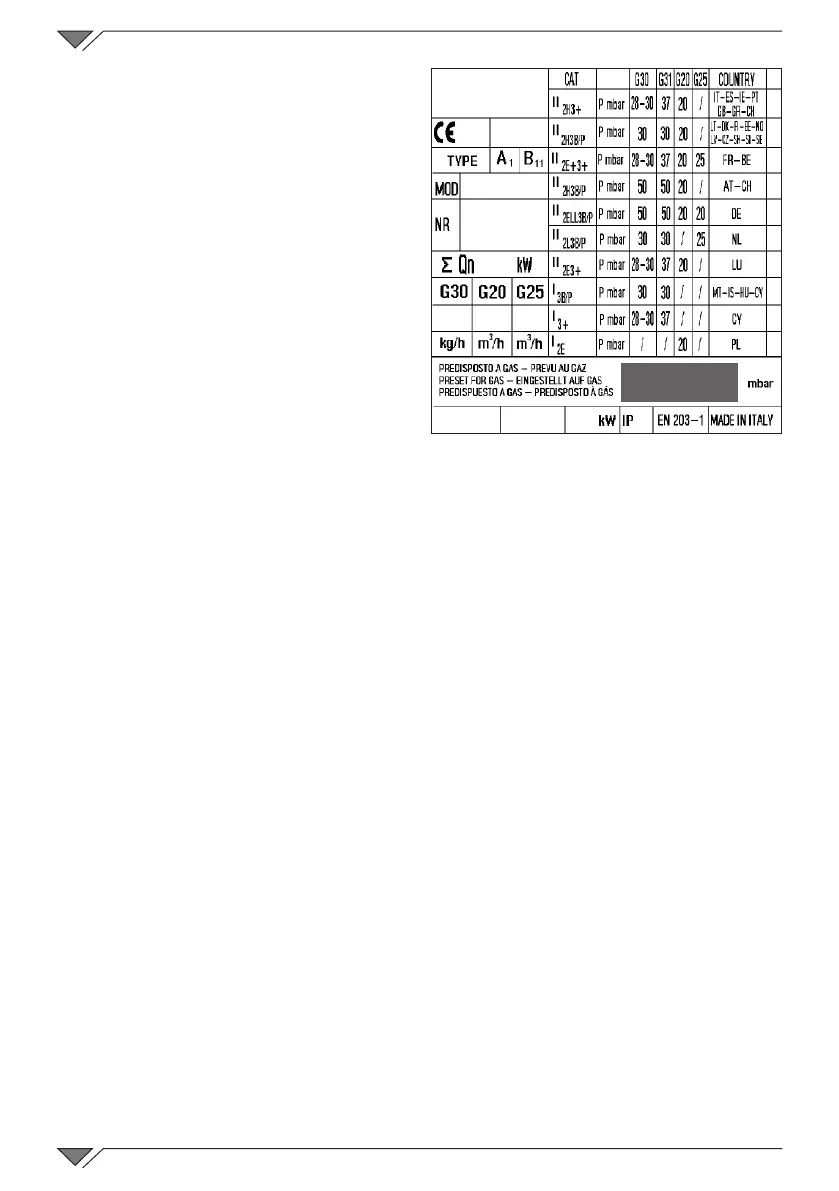

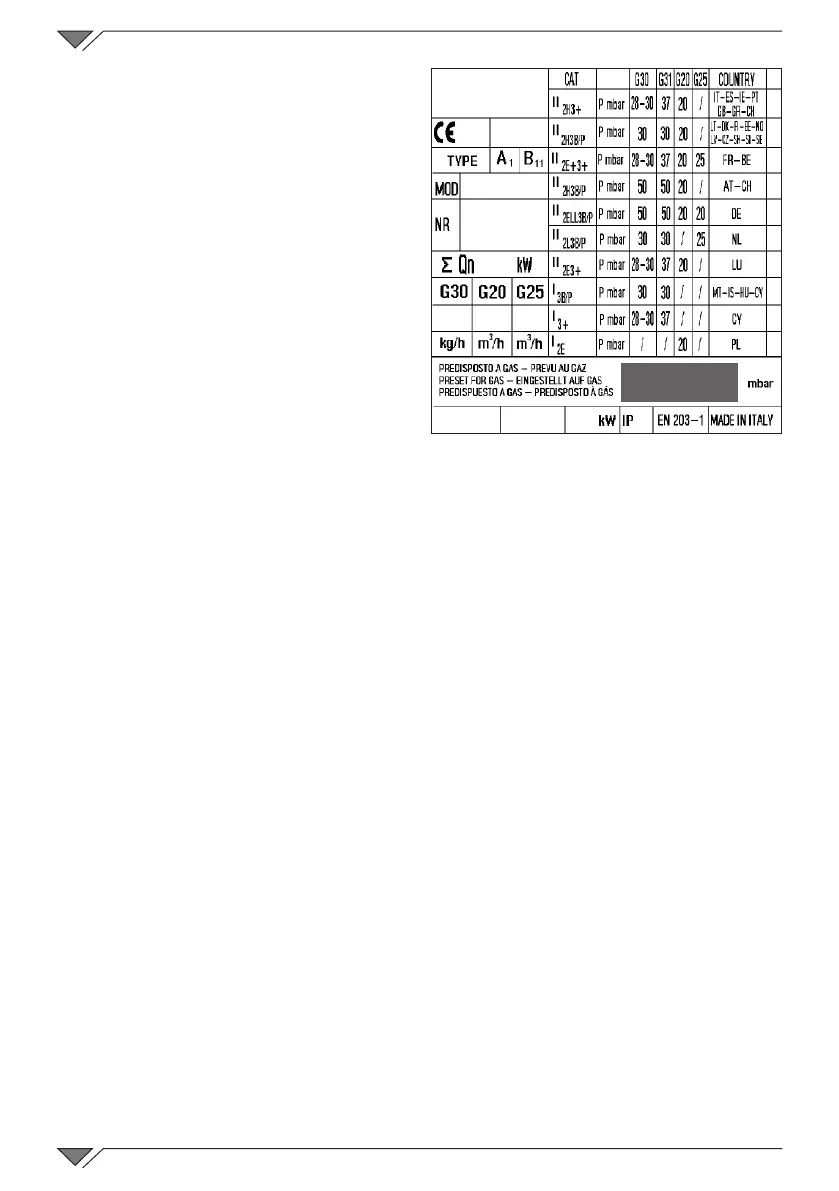

The type of gas for which the oven

is adjusted is given on the technical

plate positioned on the appliance

(Fig. 12, ref. A)�

During the inspection, make sure

that the factory calibrations on the

burners are appropriate for the

specic type of installation, through

the analysis of the gases produced by

combustion(CO2andCO)andthevericationoftheheatoutput.

Specically,withthe ovenoperatingatfull regime, thevaluesof undiluted

CO at the exhaust must remain within 1000 ppm� Should there be any

undiluted CO beyond this parameter, the burner adjustments must be checked

exclusively by a technician authorised by the manufacturer, who will make the

necessary changes to the devices which take care of the combustion and to

their parameters�

The data detected must be noted and become an integral part of the technical

documentation of said appliance�

Installation prescriptions

The oven installation and commissioning operations must be performed by

qualiedstaffonlyincompliancewithrulesandregulationsinforce.

The gas plants, the electric connections and the places of installation of the

appliances must be in compliance with the regulations and the standards in force�

Remember that the air necessary for combustion of the burners is 2 m³/h per kW

of power installed�

In businesses open to the public, accident-prevention regulations must be

compliedwithalongwithre-preventionsafetyandanti-panicregulations.

Theconnectiontothegassupplyttingcanbemadeusingexiblemetal

hoses; placing a type-approved cut-off cock in an easily accessible point�

Makesurethattheexiblemetalhose,forconnectiontothegasinlettting,

does not touch the hot parts of the oven and that it is not subjected to twisting

or extension�

Usexingstrapsthatareincompliancewiththeinstallationregulations.

Fig. 12

A

Loading...

Loading...