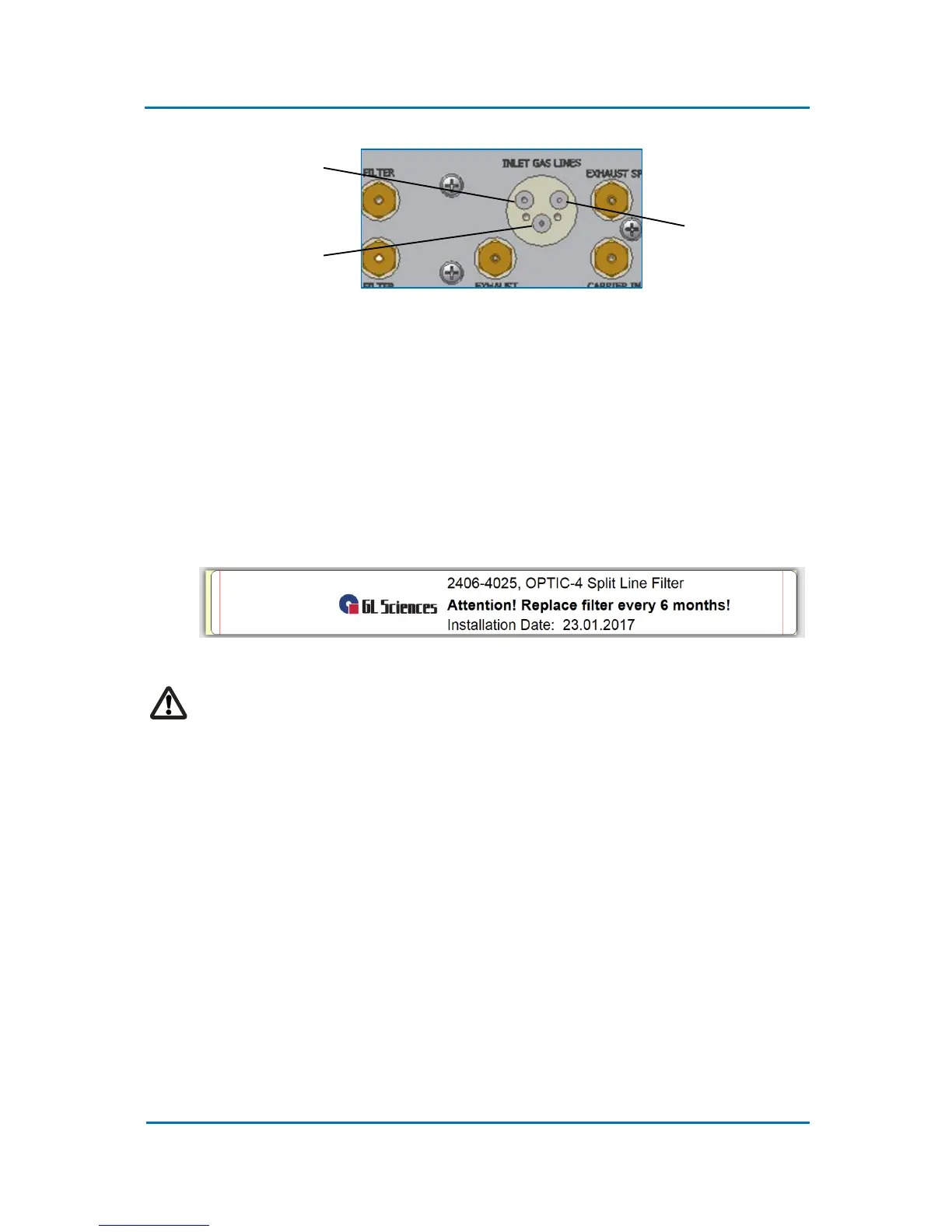

Figure 4.2 Inlet Gas Lines Connections Designation

4.2.3 Split Line Filter

An active carbon filter is installed in the split line in order to protect the EFC from

contamination by residual sovent vented through this line. The filter is mounted on the EFC

manifold using standard compression fittings and is installed at the factory. The filter does

not have a breakthrough indicator warning about its saturation. In order to avoid the work

with the saturated filter, it must be replaced every 6 months. The filter is always supplied

with a label tag attached to it (Fig. 4.3). The installation date must be written on the tag

during initial installation as well as after the filter replacement.

Figure 4.3 Split Line Filter Tag

CAUTION!

Do not apply excessive force while replacing the filter as it can lead to the filter thread

damage. Tighten the filter by hand until its o-ring makes contact with the EFC manifold

and then use a wrench to turn it additionally quarter of a turn.

4.2.4 External solvent Monitor

NOTE!

Do not place the external solvent monitor above surface which may become very warm or

hot as this may disrupt the sensor readings.

The OPTIC-4PTV version is delivered with an external solvent monitor. It should be installed into the

inlet split line using the pneumatic fittings and seals supplied with the External Monitor Kit. In order

to prevent the monitor’s signal drift, it should be placed as far as possible from the GC hot zone.

Preferably, the monitor should be installed above the gas control compartment.

The solvent monitor electrical signal cable should be connected to the “Ext Solvent Monitor”

connector on the rear panel of the instrument (Fig. 4.1).

Loading...

Loading...