-26-

Model G0824 (Mfd. Since 12/16)

6. To ensure carriage components do not unex-

pectedly move during the following steps,

disengage half nut lever and feed selection

lever (see Figure 26). Rotate carriage and

cross slide handwheels back and forth while

moving levers to verify they are disengaged.

When disengaged, handwheels will turn with

ease.

3.

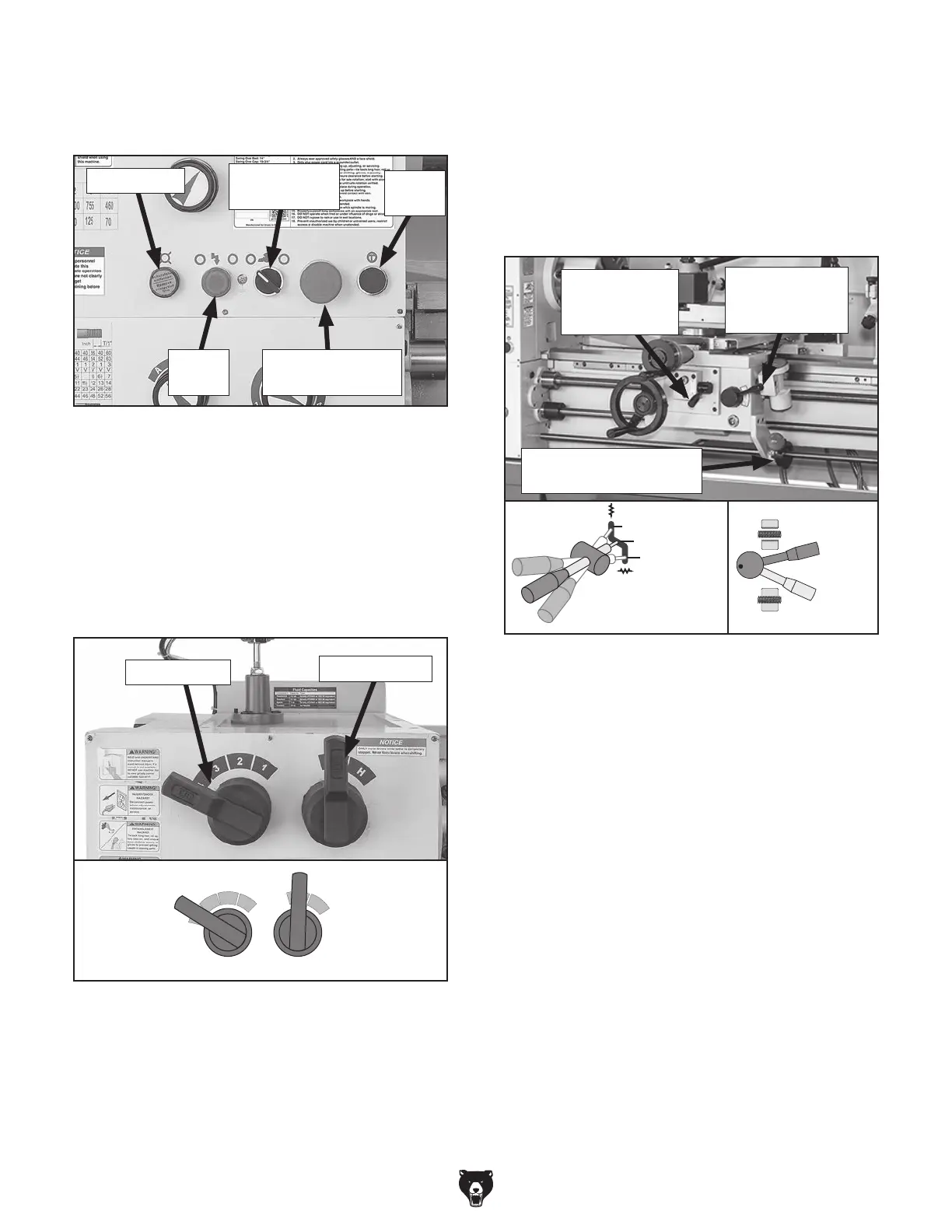

Push Emergency Stop/RESET button on

control panel (see Figure 24), and point cool-

ant nozzle into chip pan.

7.

Rotate Emergency Stop/RESET button clock-

wise so it pops out. Power light on the control

panel should illuminate.

8.

Push power button, then move spindle lever

(see Figure 26) down to start spindle. The

top of the chuck should turn down and toward

front of lathe.

—

When operating correctly, machine will

run smoothly with little or no vibration or

rubbing noises.

— Investigate and correct strange or unusual

noises or vibrations before operating

machine further. Always disconnect

machine from power when investigating

or correcting potential problems.

Engaged

Half Nut

Lever

Disengaged

Cross Slide

Feed Selection

Lever

Carriage

Spindle Lever

(OFF, Center Position)

Figure 26. Disengaging carriage components.

Figure 24. Control panel buttons used in test

run.

Coolant

Pump Switch

Jog

Button

Emergency Stop/

RESET Button

Power

Button

Power Light

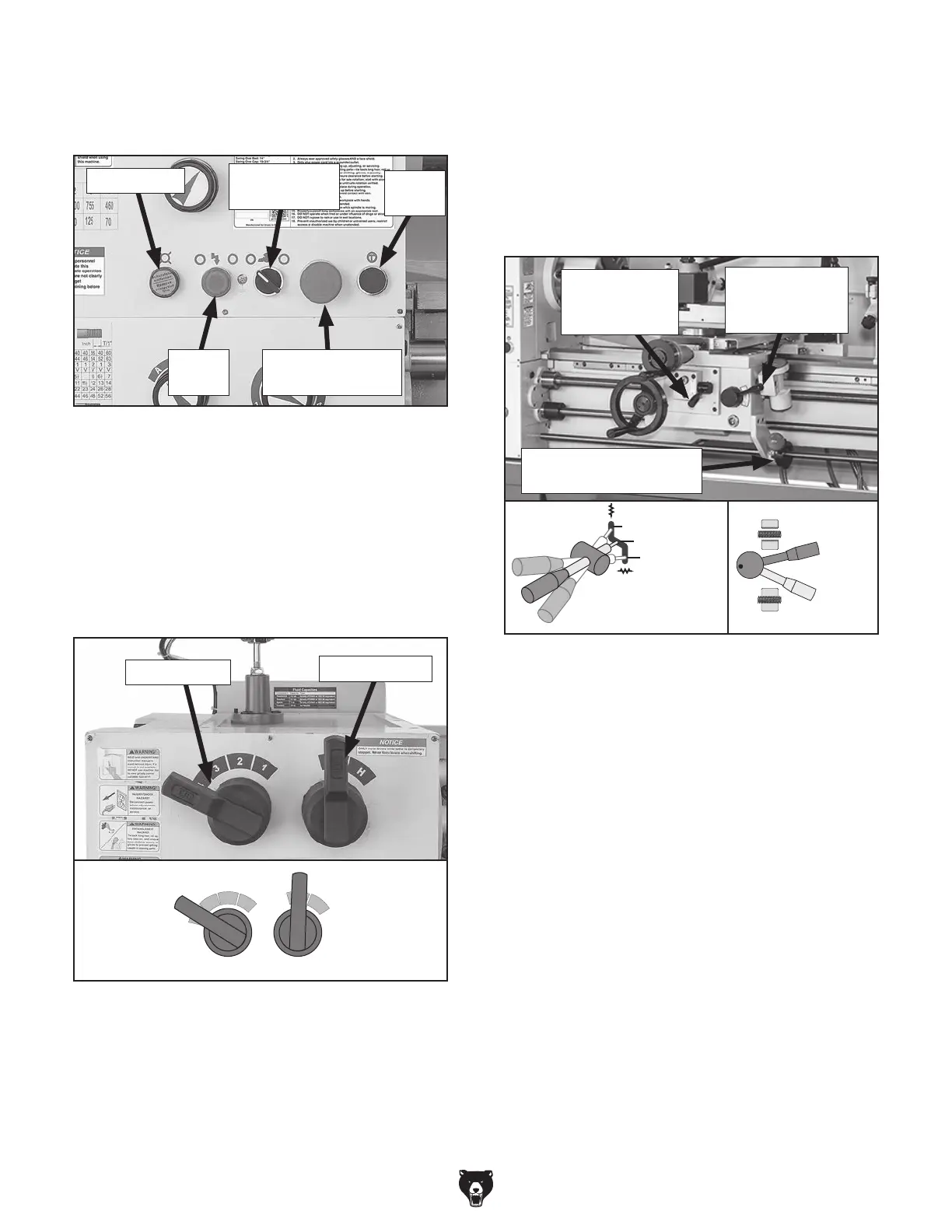

4. Move spindle speed and speed range levers

to L and 4. This will set spindle rotation at 70

RPM (see Figure 25).

Note: In the next step, you may need to rock

the chuck back and forth as you make the

adjustments to cause the gears to mesh.

Figure 25. Spindle speed set to 70 RPM.

Speed

Lever

Set to "4"

Speed

Range

Lever

Set to "L"

1

2

3

4

H

L

Speed Lever

Speed Range

5. Make sure spindle lever is in OFF (middle)

position (see Figure 26) to prevent unex-

pected startup when power is enabled.

Note: You need to pull the lever out (or right)

to disengage the lug in order to adjust the

position.

Feed Lever is

Horizontal

(Disengaged)

Half Nut Lever

is Pulled Up

(Disengaged)

Loading...

Loading...