-74-

Model G0824 (Mfd. Since 12/16)

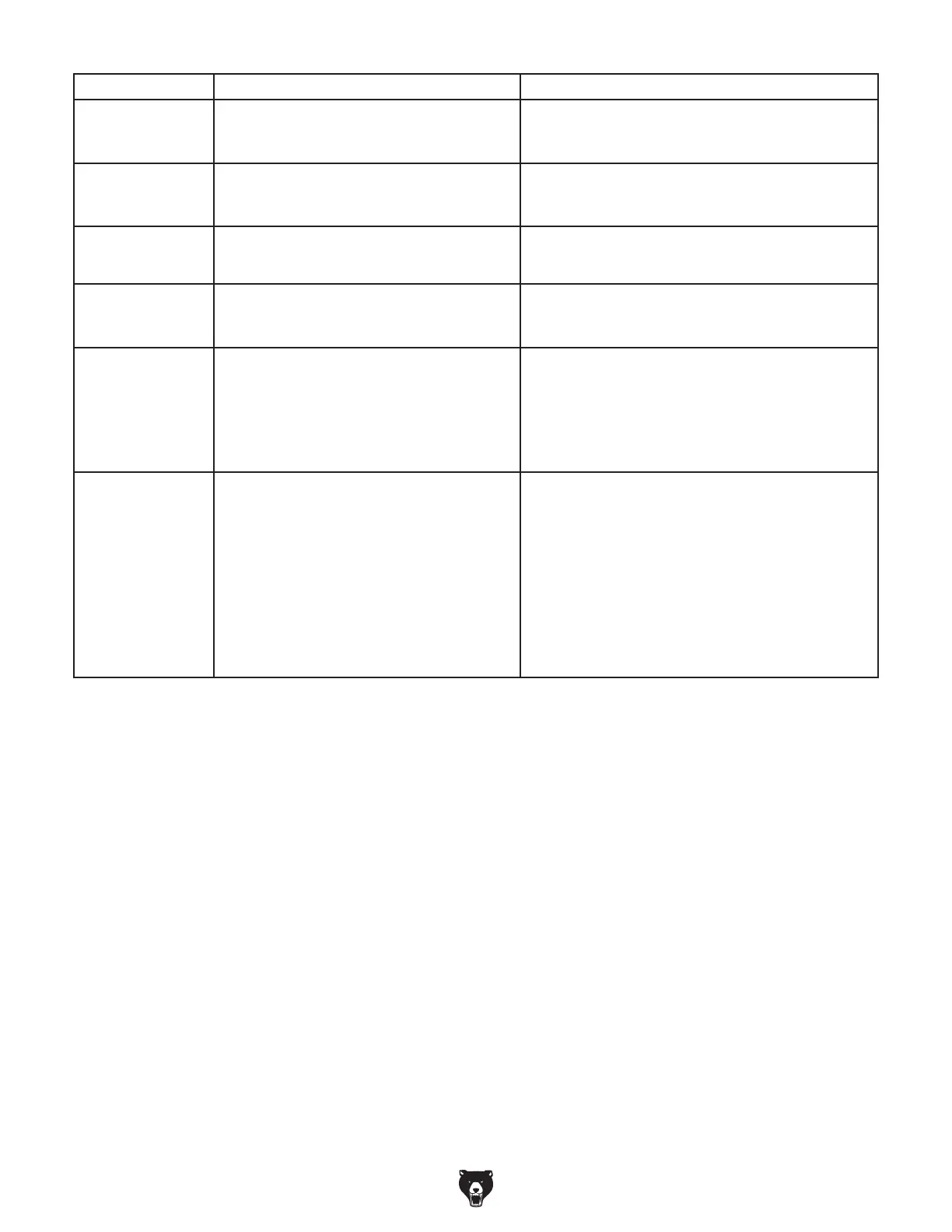

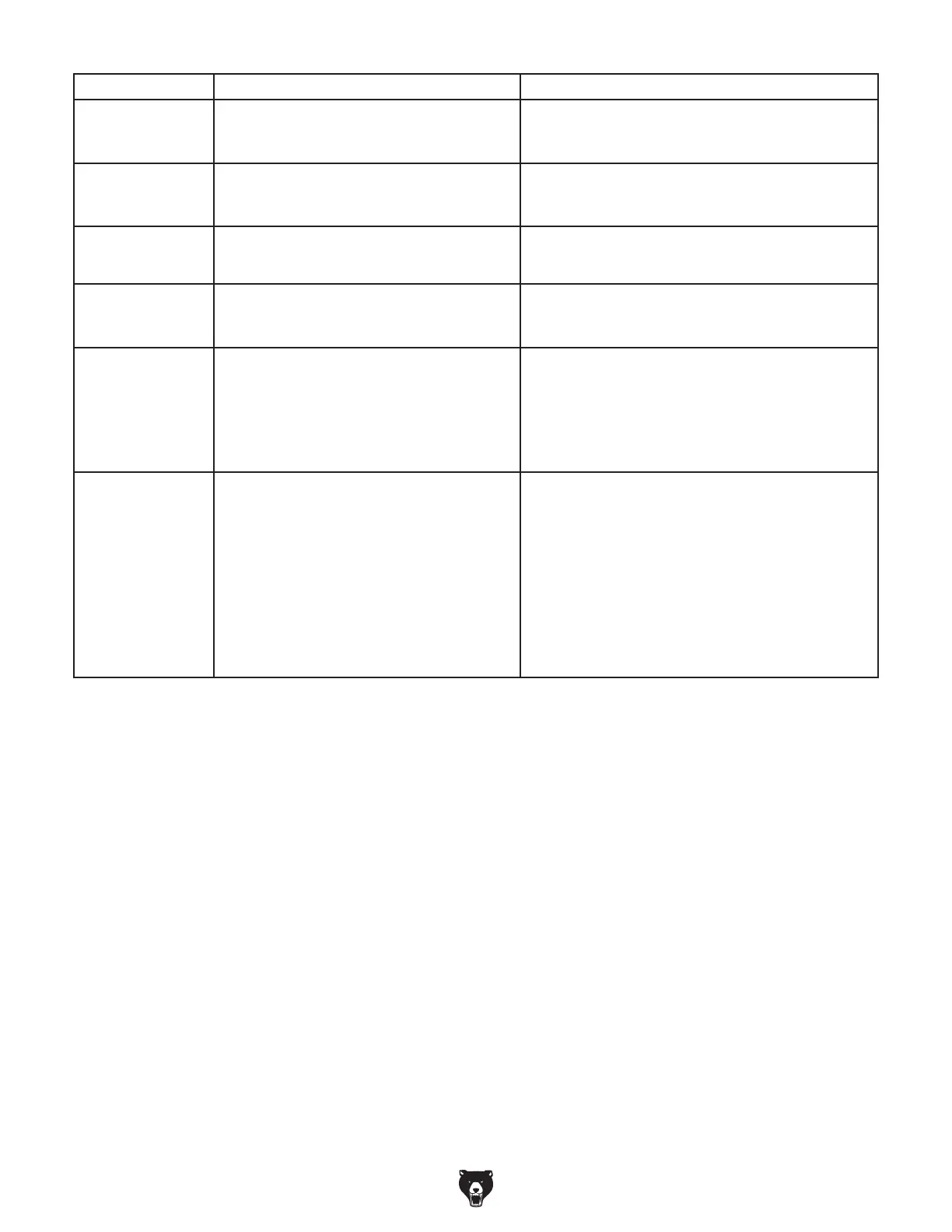

Symptom Possible Cause Possible Solution

Workpiece is

tapered.

1. Spindle and tailstock centers are not

properly aligned with each other.

2. Lathe bed is twisted.

1. Re-align tailstock to headstock spindle centerline

(Page 38).

2. Level lathe (Page 23).

Chuck jaws will

not move or do not

move easily.

1. Chips are lodged in jaws or scroll plate.

2. Dent/ridge in jaw slot of chuck body.

1. Remove jaws, clean and lubricate scroll plate, then

re-install jaws.

2. Stone or file off high spot in jaw slots.

Spindle lacks

turning power or

starts up slowly.

1. Belts are slipping. 1. Tighten belts (Page 79); inspect for oil/grease on

belts and clean/replace as necessary.

Gear change dials

will not shift into

position.

1. Gears not aligned inside headstock/quick-

change gearbox.

1. Rotate spindle by hand with light pressure on the

dial until gears fall into place.

Workpiece slips in

chuck.

1. Chuck jaws do not match workpiece

diameter.

2. Cutting pressure/feed rate is too high.

3. Spindle speed is too high.

4. Jaws are worn or not installed properly.

1. Reposition or mold workpiece so that diameter

matches chuck jaw dimensions.

2. Reduce cutting force.

3. Reduce spindle speed (Page 49).

4. Remove/re-install properly; turn jaws with cutting

tool so they are concentric; replace jaws or chuck.

Carriage will not

feed or is hard to

move.

1. Gears are not all engaged.

2. Half nut lever is engaged.

3. Carriage lock is tightened down.

4. Screw is loose on feed handle.

5. Chips have loaded up on ways.

6. Ways are dry and in need of lubrication.

7. Gibs are too tight.

8. Gears broken.

9. Feed clutch is slipping.

1. Engage gears using gear dials.

2. Disengage half nut lever.

3. Check to make sure carriage lock is fully released.

4. Tighten.

5. Frequently clear away chips that load up during

turning operations.

6. Lubricate bedways/ball oilers (Page 66).

7. Loosen gib screw(s) slightly (Page 77).

8. Replace gears.

9. Increase clutch spring pressure (Page 81).

Loading...

Loading...