English (GB)

40

13.12 "Controller" (Controller settings)

The pumps have a factory default setting of gain (K

p

)

and integral time (T

i

).

However, if the factory setting is not the optimum

setting, you can change the gain and the integral

time:

• Set the gain within the range from 0.1 to 20.

• Set the integral-action time within the range from

0.1 to 3600 seconds.

If you select 3600 seconds, the controller

functions as a P controller.

Furthermore, you can set the controller to inverse

control.

This means that if you increase the setpoint, the

speed is reduced. In the case of inverse control, you

must set the gain within the range from -0.1 to -20.

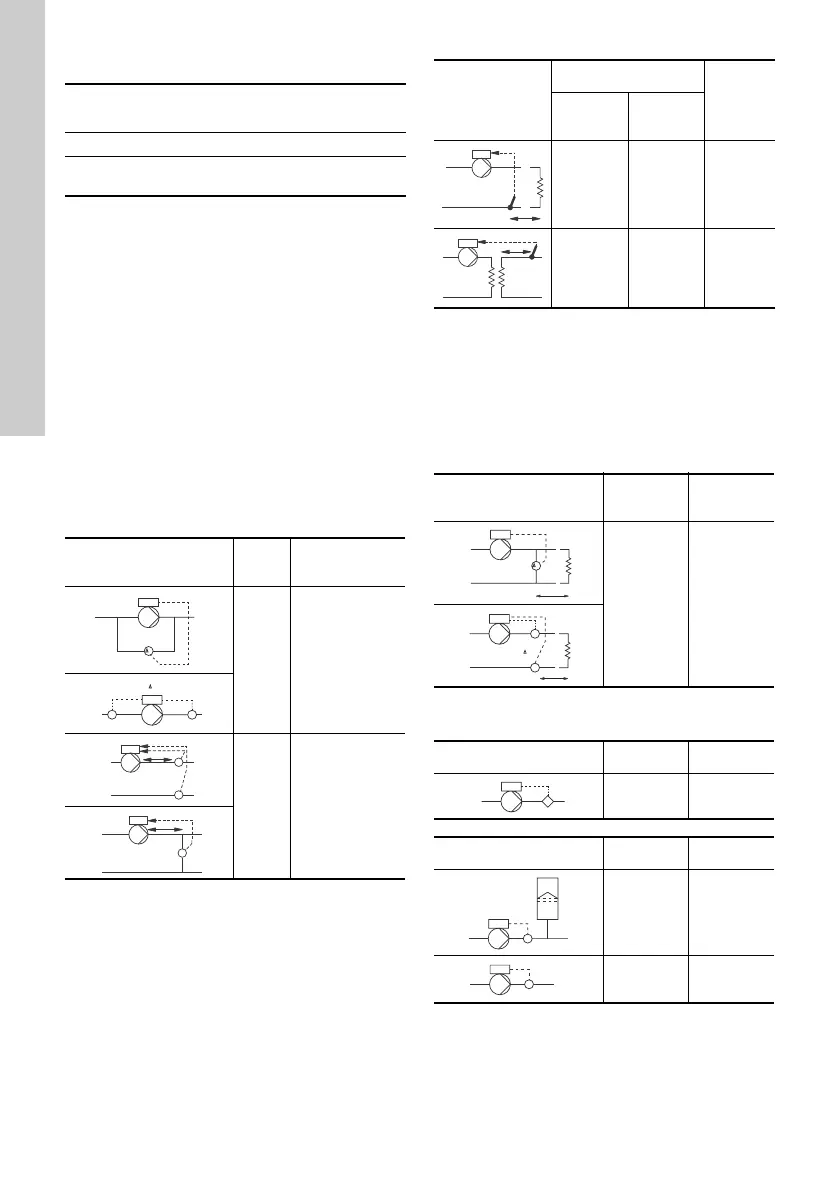

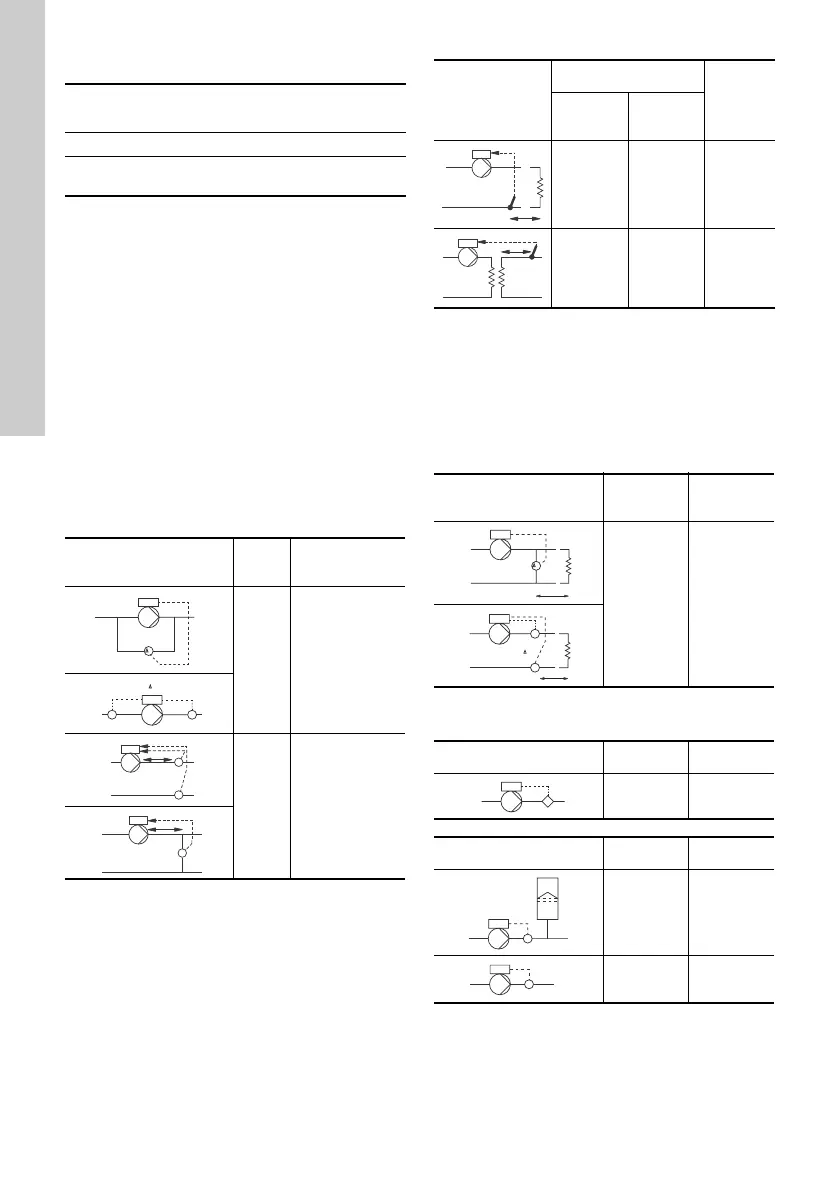

Guidelines for setting of PI controller

The tables below show the recommended controller

settings:

L1: distance in metres between pump and sensor.

1)

In heating systems, an increase in pump

performance results in a rise in temperature at

the sensor.

2)

In cooling systems, an increase in pump

performance results in a drop in temperature at

the sensor.

L2: distance in metres between heat exchanger and

sensor.

L2: Distance [m] between heat exchanger and

sensor.

Pump variant

"Controller"

(Controller settings)

CME ●

CRE, CRIE, CRNE,

SPKE, MTRE

●

Constant differential

pressure

K

p

T

i

0.5 0.5

0.5

L1 < 5 m: 0.5

L1 > 5 m: 3

L1 > 10 m: 5

Constant

temperature

K

p

T

i

Heating

system

1)

Cooling

system

2)

0.5 -0.5 10 + 5L2

0.5 -0.5 30 + 5L2

Constant differential

temperature

K

p

T

i

-0.5 10 + 5L2

Constant flow rate K

p

T

i

0.5 0.5

Constant pressure K

p

T

i

0.5 0.5

0.5 0.5

Loading...

Loading...