English (GB)

71

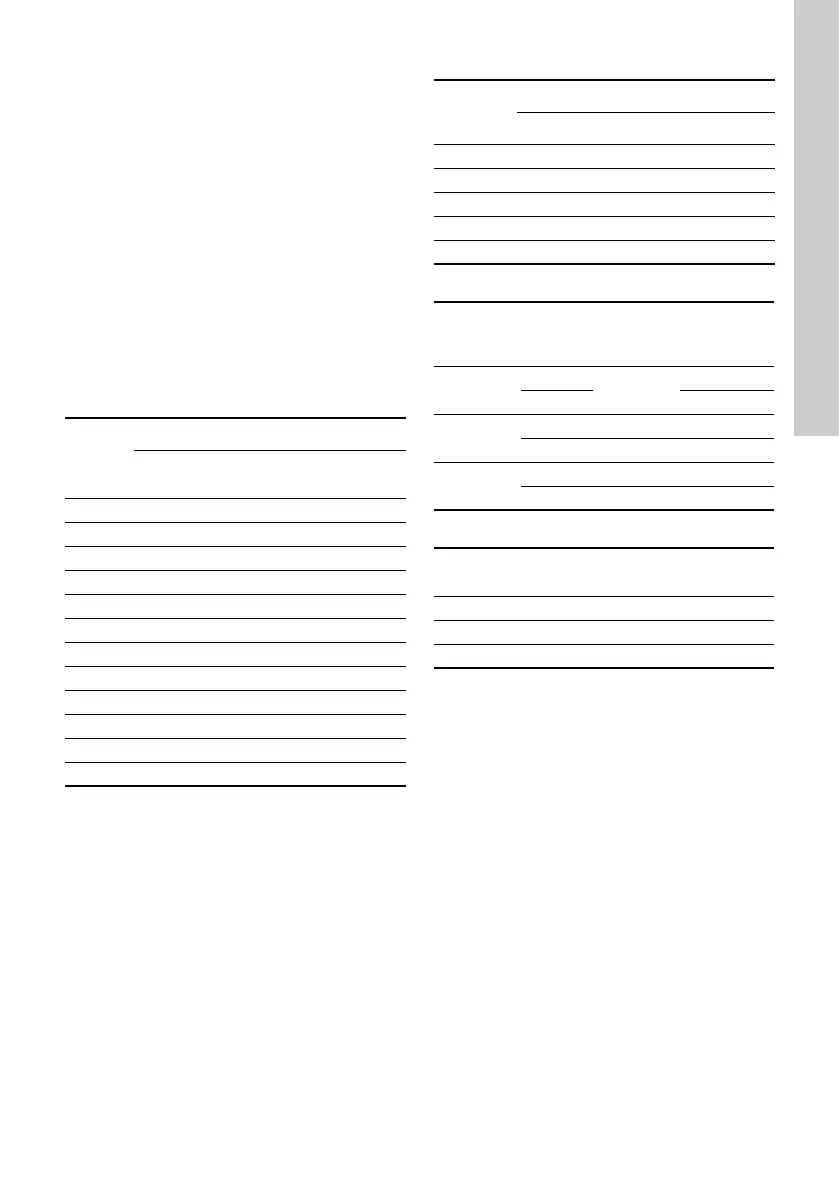

29. Other technical data

EMC (electromagnetic compatibility)

Standard used: EN 61800-3.

The table below shows the emission category of the

motor.

C1 fulfils the requirements for residential areas.

Note: When connected to a public network, 11 kW

motors do not comply with the partial weighted

harmonic distortion (PWHD) requirements of EN

61000-3-12. If required by the distribution network

operator, compliance can be obtained in the

following way:

The impedance of the mains cables between the

motor and the point of common coupling (PCC) must

be equivalent to the impedance of a 50 m cable with

a cross-section of 0.5 mm.

C3 fulfils the requirements for industrial areas.

Note: When the motors are installed in residential

areas, supplementary measures may be required as

the motors may cause radio interference.

*

C1, if equipped with an external Grundfos EMC

filter.

Immunity: The motor fulfils the requirements for

industrial areas.

Contact Grundfos for further information.

Enclosure class

Standard: IP55 (IEC 34-5).

Optional: IP66 (IEC 34-5).

Insulation class

F (IEC 85).

Standby power consumption

5-10 W.

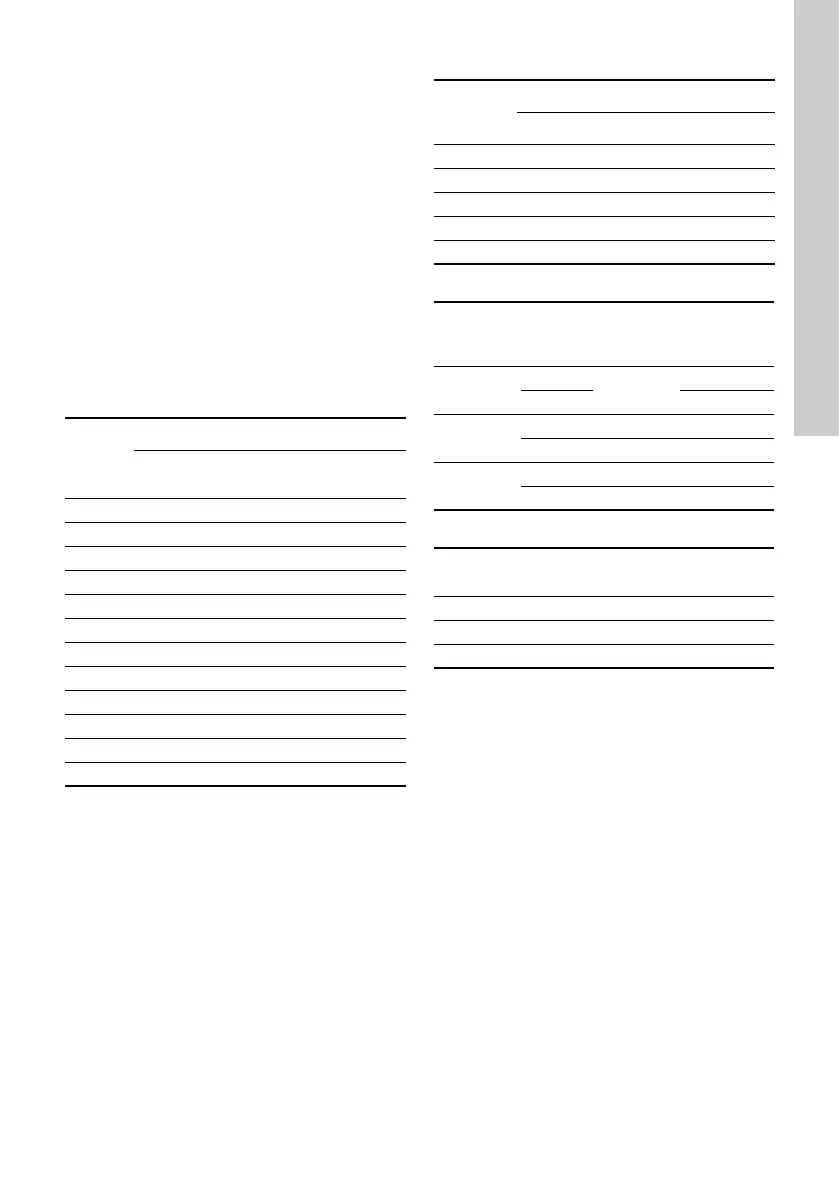

Cable entries

Cable glands delivered with the pump

Torques

Motor

[kW]

Emission category

1450-2000 min

-1

2900-4000 min

-1

4000-5900 min

-1

0.25 C1 C1

0.37 C1 C1

0.55 C1 C1

0.75 C1 C1

1.1 C1 C1

1.5 C1 C1

2.2 C1 C1

3C1 C1

4C1 C1

5.5 C3/C1* C1

7.5 C3/C1* C3/C1*

11 - C3/C1*

Motor

[kW]

Number and size of cable entries

2900-4000 min

-1

4000-5900 min

-1

0.25 - 1.5 4xM20 4xM20

2.2 4xM20 4xM20

3-4 1xM25 + 4xM20 1xM25 + 4xM20

5.5 1xM25 + 4xM20 1xM25 + 4xM20

7.5 - 11 1xM32 + 5xM20 1xM32 + 5xM20

Motor

[kW]

Quantity

Thread

size

Cable

diameter

[mm]

0.25 - 2.2

2

M20 x 1.5

5

17-14

3 - 5.5

4 M20 x 1.5 5

1 M25 x 1.5 9-18

7.5 - 11

4 M20 x 1.5 5

1 M32 x 1.5 14-25

Terminal Thread size

Maximum torque

[Nm]

L1, L2, L3, L, N M4 1.8

NC, C1, C2, NO M2.5 0.5

1-26 and A, Y, B M2 0.5

Loading...

Loading...