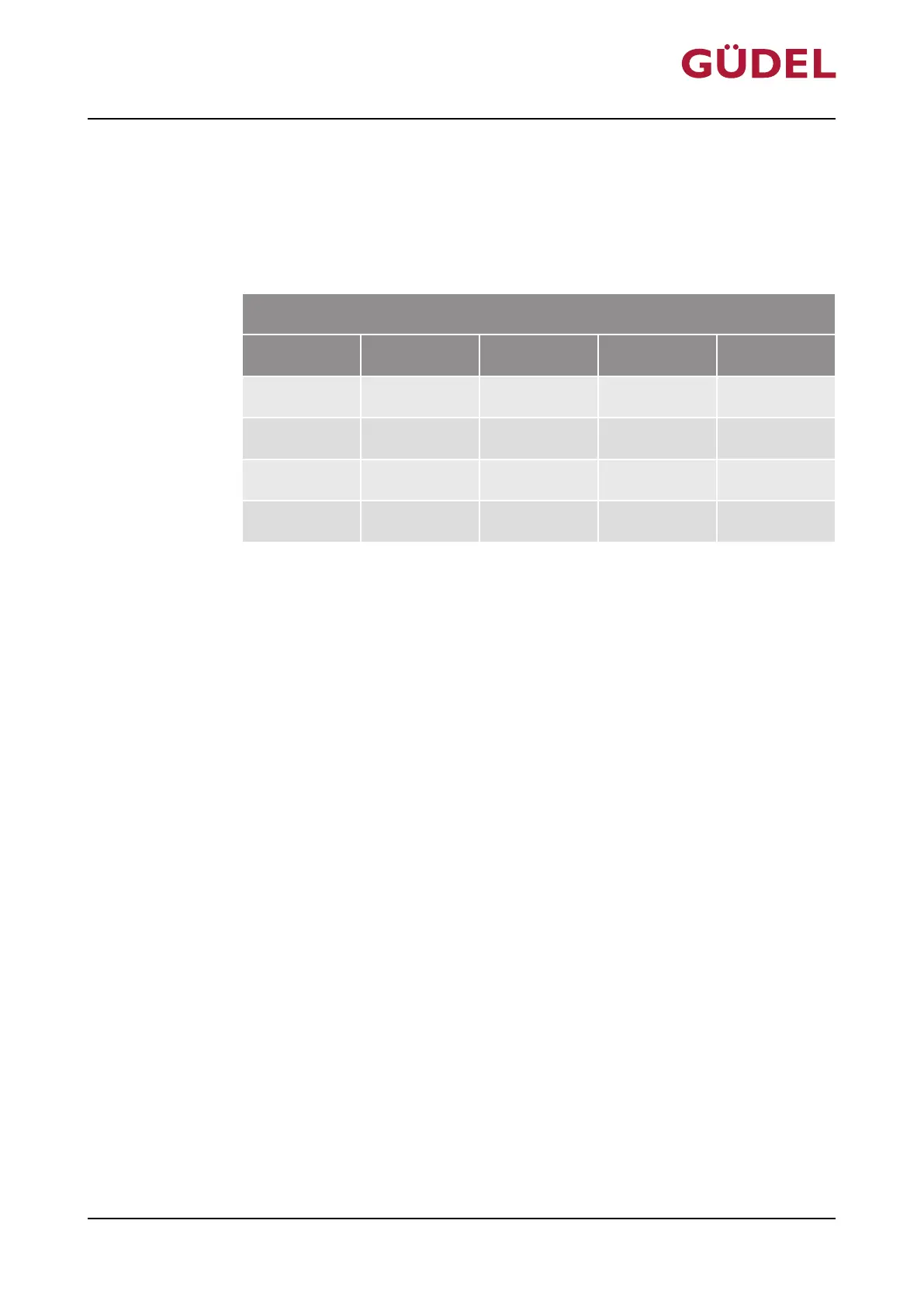

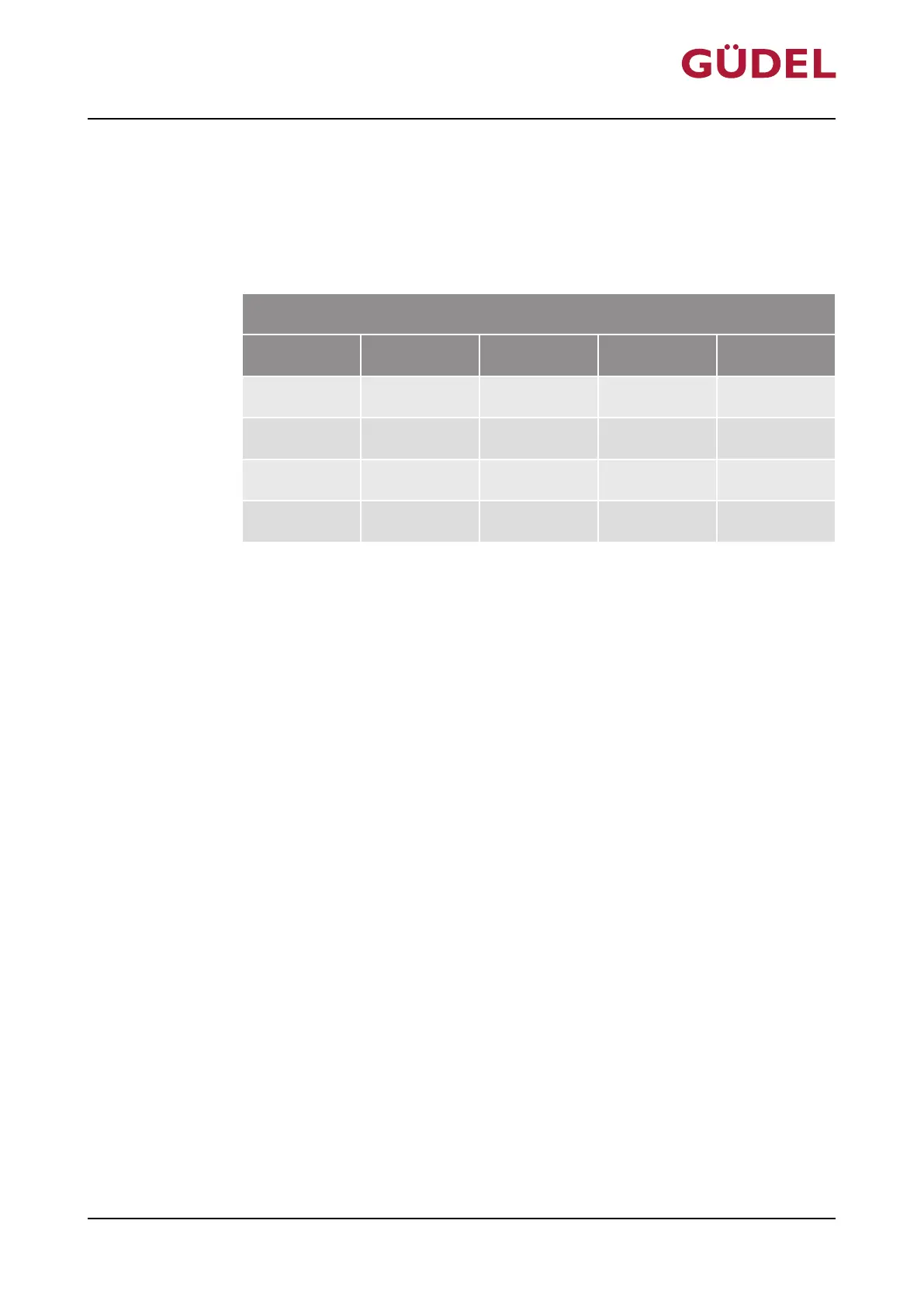

Duty cycle

The maintenance intervals refer to the effective operating hours of the prod-

uct at a duty cycle (ED) of 100%. The duty cycle always refers to the entire

process. This means that the duty cycle of specific axes cannot be considered

individually.

Duty cycle

100% 80% 60% 40% 20%

2000 2,500 3,300 5,000 10,000

6,000 7,500 10,000 15,000 30,000

10,000 12,500 16,500 25,000 50,000

20,000 25,000 33,000 50,000 100,000

Tab.7-7 Conversion table: Operating hours at the respective duty cycle

Operating conditions

Normal operating conditions are assumed, which correspond to the parame-

ters defined by Güdel when designing the product. If they are rougher than

assumed, products may fail earlier. Adjust the maintenance intervals to your

operating conditions if necessary.

With prudent operation you can protect your product. Observe the permissi-

ble performance limits of the product.

Avoid, in particular:

• Operation near or above the permissible performance limits

• High acceleration and resulting vibrations and operating forces

• Abrasive and/or corrosive environmental conditions

• Long duty cycles

• Always the same axis positions under high load

Maintenance

OPERATING MANUAL Lubrication system

FlexxPump4D

9007202674126091_v2.0_EN-US

77

Loading...

Loading...