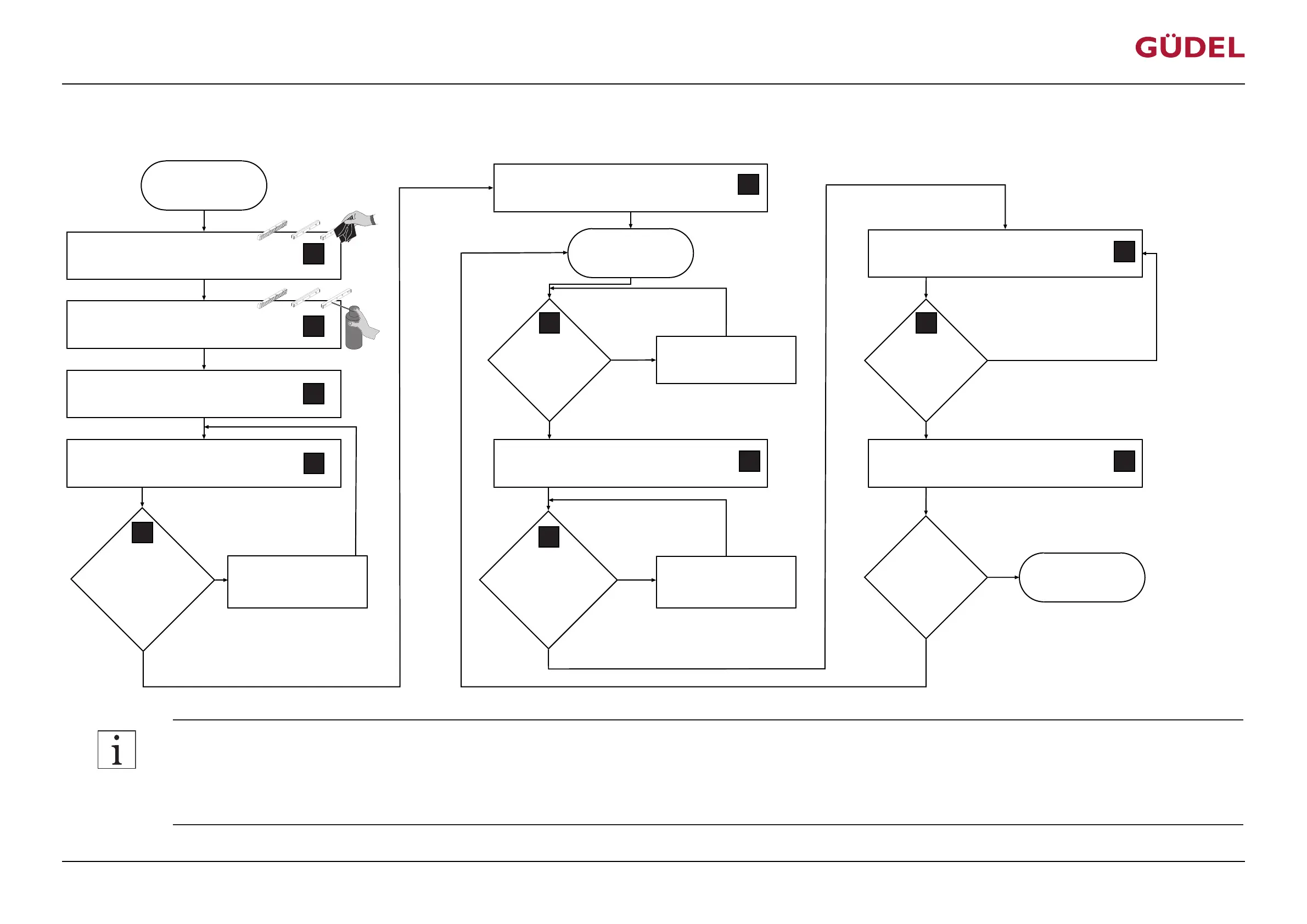

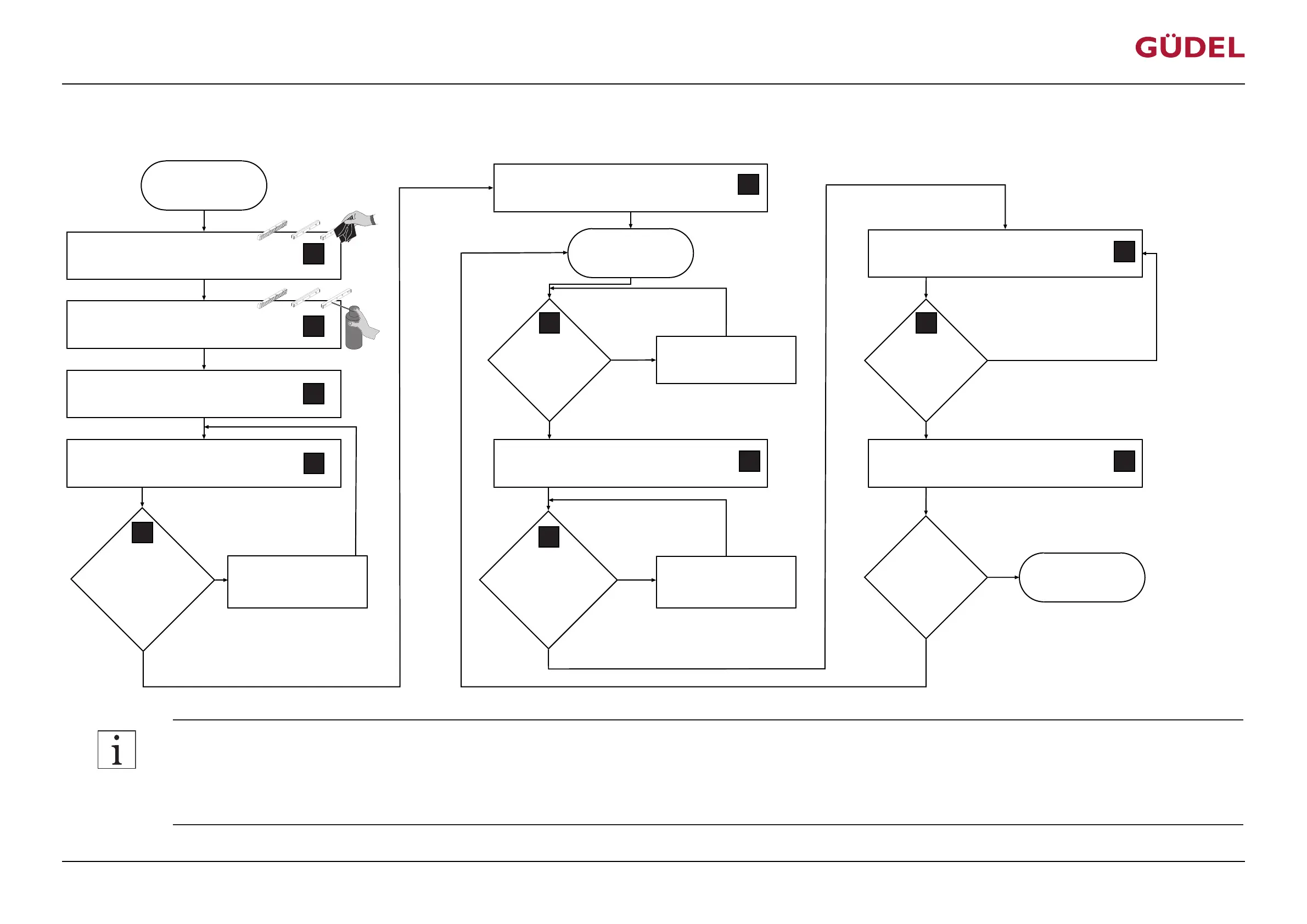

7.3.2.2 Checking the lubrication system

Start

End

Clean the rails and racks

Lubricate rails and racks with lubricating spray

(material number 10406825)

Remove all lubrication lines from the lubricant pump

Start the lubricant pump's lubrication cycle

Does lubricant flow

out at all hydraulic

outputs of the lubricant

pump?

Mount all lubrication lines on the hydraulic outputs of

the lubricant pump

Fill lubrication line with

lubricant. Remove air in

lubrication line. Remove kinks

Start the lubricant pump's lubrication cycle

Expose lubrication point Remount lubrication point

Yes

No

Is the lubrication line

filled without air

bubbles and kinks?

Yes

No

Check voltage supply and

function of the lubricant pump

and correct if necessary

Replace lubricating element /

lubricating pinion if necessary,

then pre-lubricate

Lubricating element /

lubricating pinion

saturated with

lubricant and intact?

Yes

No

Does lubricant flow

out at lubrication

point?

Yes

No

Other lubrication

points available?

Yes

No

Start lubrication point check

I

II

III

IV

VI

V

VII

VIII

IX

X

XI

XII

• After cleaning work or during standstill times of 1 to 4 weeks, check the lubricant film on the rails and racks (II) and the lubrication lines for air bubbles and kinks (VII) before commissioning. If nec-

essary, carry out a check of the complete lubrication system.

• As operator, check the lubrication system during initial commissioning, after standstill times of more than 4 weeks, if lubricant film is not present, and after the lubricant cartridge or the lubricant

pump of the lubrication system has been replaced.

The operator is always responsible for adequate and properly functioning lubrication.

MaintenanceOPERATING MANUAL Lubrication system FlexxPump4D

9007202674126091_v2.0_EN-US

83

Loading...

Loading...