HQ In nity User Manual | 2 9

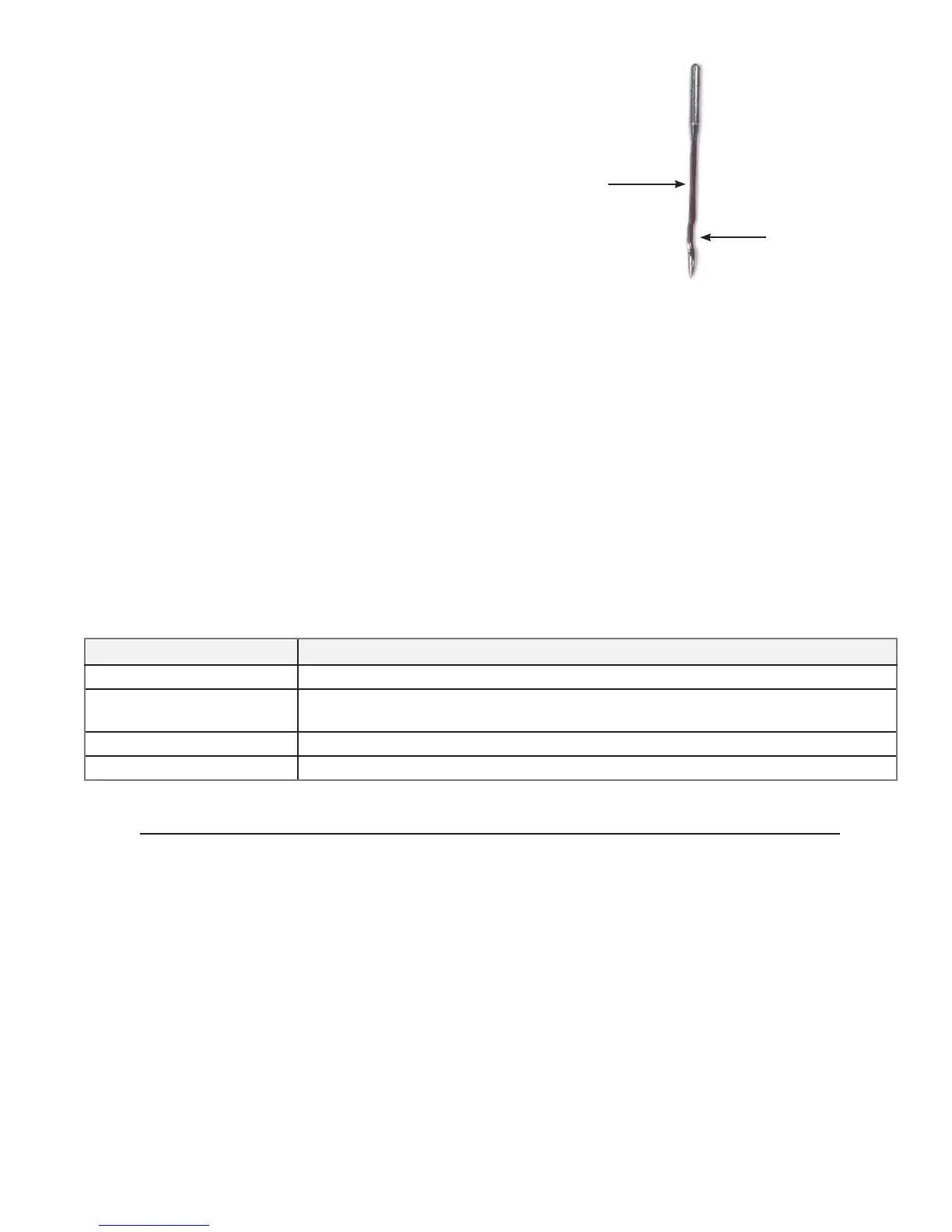

The In nity uses the MR needle system. Note that the needle has a

round shank rather than a shank with a at side like home sewing

m ac h i n e s u s e .

If you use the recommended needle, you will experience:

• Fewer skipped s tches

• Less needle breakage

• Less thread breakage, especially at high speeds

• Less thread splicing or shredding

• Op mum fabric protec on

IMPORTANT: Change the needle regularly. We recommend you use a new needle for each new quilt

loaded on the machine, and any me the needle becomes bent, dull, or burred.

U CAUTION: A damaged needle may result in poor s tching quality or may even damage the machine

or your quilt.

To change the needle

ONLINE: For more informa on about changing the needle, watch the video Changing the Needle at:

h p://www.handiquilter.com/videos/hq-in nity/222/.

1 . Move the needle bar to the up posi on by pressing the needle up/down control on the handles.

2 . Turn o all power to the machine.

3. Loosen the needle bar clamp screw with the

2.5mm hex wrench.

4 . Remove the old needle by pulling it down. Discard the old needle in a safe way.

5 . With the scarf of the needle (indenta on at

the back of the needle) facing the rear of the

machine and the long groove down the front

o f t h e n e e d l e f ac i n g t h e f r o n t o f t h e m a c h i n e ,

push the needle all the way up into the needle

bar un l it stops. Check the sight opening to

verify that the top of the needle can go no

farther up.

U CAUTION: Check the needle to con rm it is fully inserted. The needle bar has a sight opening

above the needle bar clamp screw. Make sure the needle is touching the top of the sight opening.

If it isn’t, the machine ming will be o and it may be possible for the needle to collide with

internal parts causing damage not covered by warranty.

6. Carefully ghten the needle bar clamp screw.

U CAUTION: Although you can use your ngers to ghten the needle bar clamp screw, we recommend

that a er nger- ghtening the screw you use the 2.5mm hex wrench to ghten it just a bit more.

The In nity runs at very high speeds and this ensures the needle will not loosen while quil ng.

However, do not over ghten the needle clamp screw as this may strip the threads of the screw.

Stripped threads are not covered under the warranty. It may also become di cult to insert the

needle properly into the needle bar. Once the screw no longer turns freely by hand, gently turn the

screwdriver un l the screw is ghtened snuggly.

Needle size Thread size

12 and 14 monofi lament, 100 wt. silk, 60 wt. poly, mylar

16 monofi lament, hologram, 100 wt., 80 wt., 60 wt., 50 wt., 40 wt. silk, poly or

co on thread

18 40 wt. co ons and poly, 30 wt. co ons and poly

20 Any thread 30 wt. and heavier such as 12 wt., 19 wt., 30 wt.

Machine Quilting Tip: Needle Requirements

For general quil ng, a size 16/100 needle will accommodate most threads and fabrics.

Heavier threads, such as top s tch and some decora ve threads, require a larger needle

such as 18/110 or 20/120. Lo y ba s and heavier fabrics such as denim, canvas, or densely

woven fabric may also require a larger needle.

Hopping Feet

Your machine comes with two hopping feet: a ruler foot (comes installed) and an open-toe foot. Use the

ruler foot for everyday quil ng and ruler work, and use the open-toe foot when you need greater s tch

visibility (such as when you are micro quil ng).

ONLINE: For more informa on about changing the hopping foot, watch the video Changing the

Hopping Foot at: h p://www.handiquilter.com/videos/hq-in nity/223/.

Scarf

(/back side)

Groove

(front side)

Side view

Loading...

Loading...