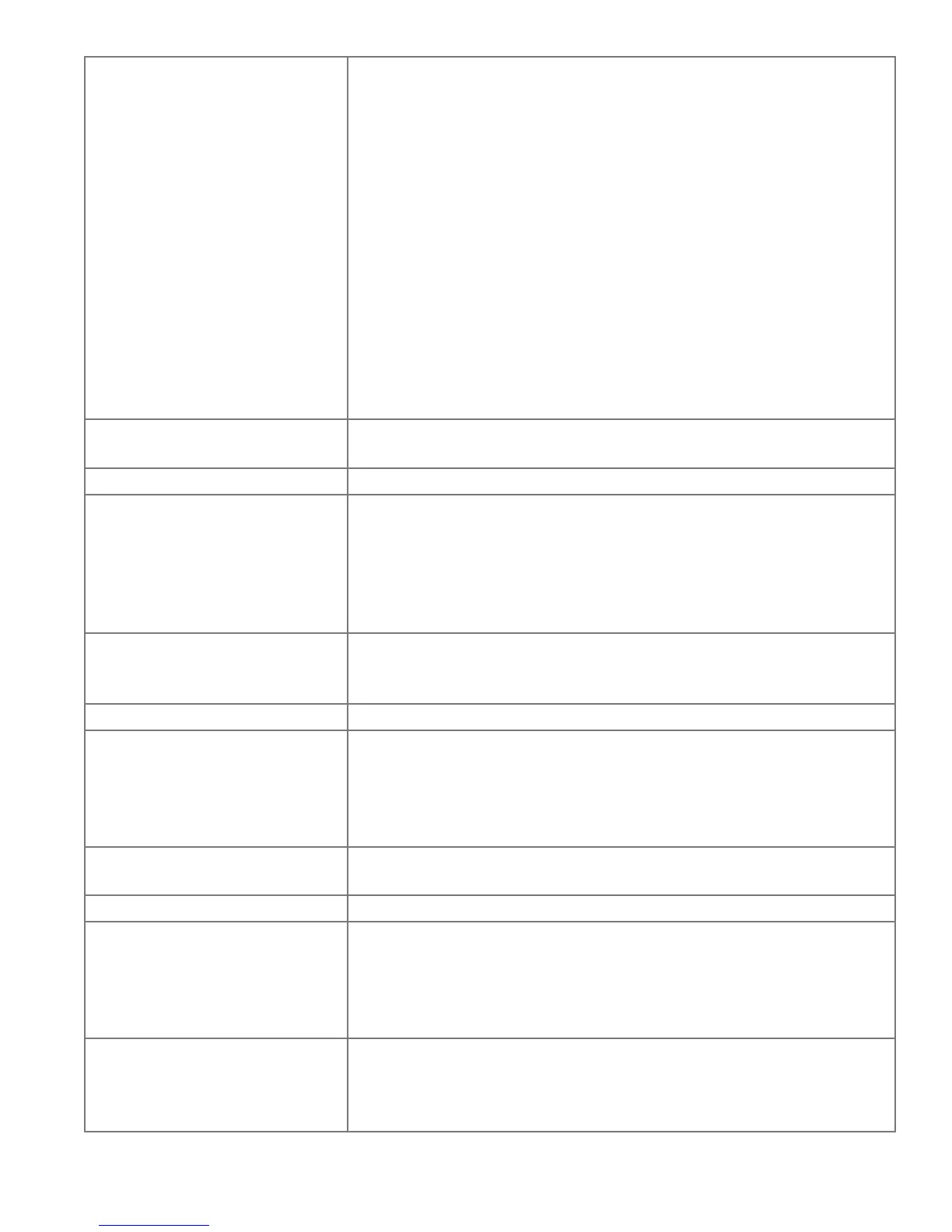

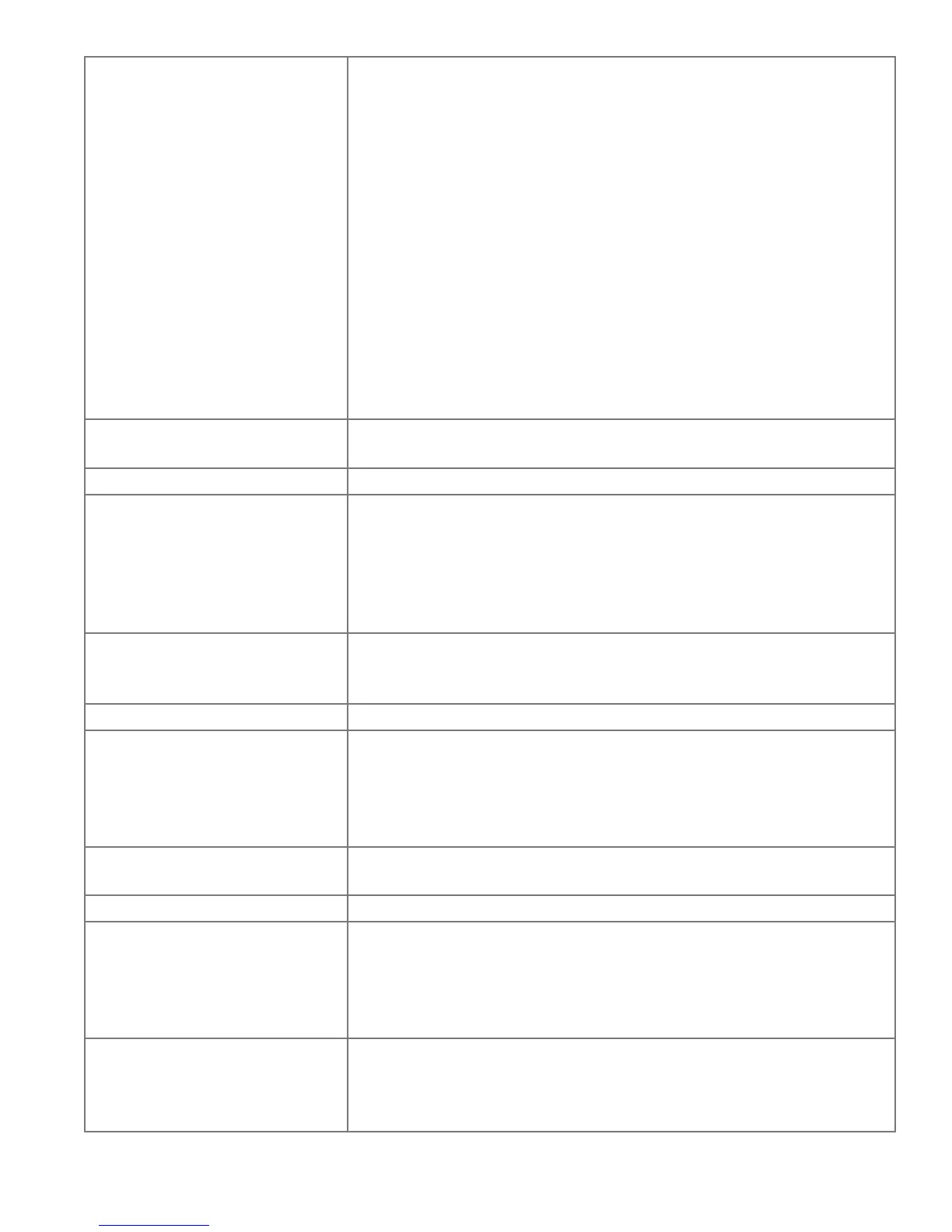

HQ Innity User Manual | 7 1

The needle is not posioned

properly

• Posion the needle properly to the needle bar. Inspect the

posion of the needle to make sure the needle is at the 6 o’clock

posion. When you stand directly in front of the needle (facing the

bobbin case side of the machine), you will see the enre needle

eye directly facing you. This is 6 o’clock posion.

• Make sure (a) the needle is installed all the way into the needle

bar to the needle-stop hole in the needle bar, (b) the long groove

in the needle is toward the front (bobbin case side), and (c) the

scarf (scooped out part of the back of the needle) is toward the

back of the machine.

• The needle can somemes be rotated to 5 o’clock (slightly right)

or 7 o’clock (slightly le) to adjust for a more posive thread loop

pickup by the hook point.

Improper threading • Ensure that the machine is threaded correctly.

The Needle Breaks Correcve Measure(s)

The needle is bent or not

installed properly

• Replace the needle. Make sure that the needle is pushed into the

needle bar clamp unl it can go no farther. Visually check that it is

up to the top of the stop/sight hole above the needle bar clamp

screw. If the needle isn’t installed properly, it can cause damage in

the bobbin area and throat plate.

The needle hits the throat plate • Correctly posion the needle, throat plate, or hopping foot.

Replace with a new needle.

Stches are Puckered Correcve Measure(s)

The tension is not balanced • Balance the tension of the needle thread aer ensuring the

bobbin tension is adjusted correctly. (For more informaon about

adjusng tension, see Bobbin and Bobbin Tension and Easy-Touch

Tension™ i n t h e Using Your Machine secon of this manual.)

Needle too large for quilng

fabric

• Replace the needle with a size beer suited for the fabric.

Poor Stch Quality Correcve Measure(s)

The tension is not balanced • Balance the tension of the needle thread aer ensuring the

bobbin tension is adjusted correctly. (For more informaon about

adjusng tension, see Bobbin and Bobbin Tension and Easy-Touch

Tension™ i n t h e Using Your Machine secon of this manual.)

Bobbin case is damaged,

corroded, dirty, etc.

• Since thread slides over the surface of the bobbin case at a high

speed, make sure the case is free of any lint or foreign maer that

could impede thread passage through the machine.

Loading...

Loading...