108 Fixed Cycles: Tapping / Thread Milling

4.2 TAPPING NEW with a Floating Tap Holder (Cycle 206, DIN/ISO: G206)

Cycle parameters

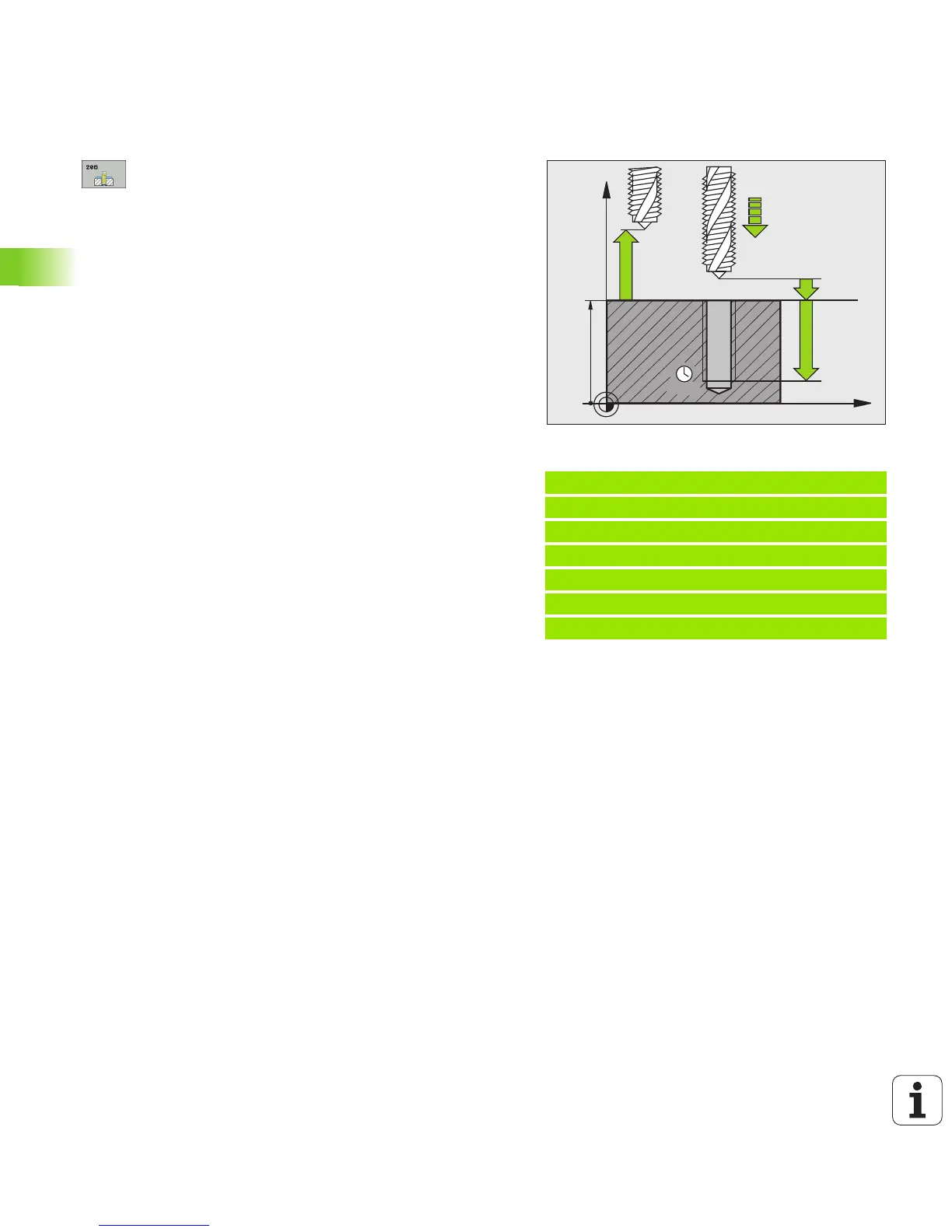

U Setup clearance Q200 (incremental): Distance

between tool tip (at starting position) and workpiece

surface. Standard value: approx. 4 times the thread

pitch. Input range 0 to 99999.9999, alternatively

PREDEF

U Total hole depth Q201 (thread length, incremental):

Distance between workpiece surface and end of

thread. Input range -99999.9999 to 99999.9999

U Feed rate F Q206: Traversing speed of the tool during

tapping. Input range: 0 to 99999.999, alternatively

FAUTO

U Dwell time at bottom Q211: Enter a value between 0

and 0.5 seconds to avoid wedging of the tool during

retraction. Input range 0 to 3600.0000, alternatively

PREDEF

U Workpiece surface coordinate Q203 (absolute):

Coordinate of the workpiece surface. Input range:

-99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

The feed rate is calculated as follows: F = S x p

Retracting after a program interruption

If you interrupt program run during tapping with the machine stop

button, the TNC will display a soft key with which you can retract the

tool.

Example: NC blocks

25 CYCL DEF 206 TAPPING NEW

Q200=2 ;SETUP CLEARANCE

Q201=-20 ;DEPTH

Q206=150 ;FEED RATE FOR PLNGNG

Q211=0.25 ;DWELL TIME AT DEPTH

Q203=+25 ;SURFACE COORDINATE

Q204=50 ;2ND SETUP CLEARANCE

Loading...

Loading...