HEIDENHAIN iTNC 530 405

16.4 MEASURE ANGLE (Cycle 420, DIN/ISO: G420)

16.4 MEASURE ANGLE (Cycle 420,

DIN/ISO: G420)

Cycle run

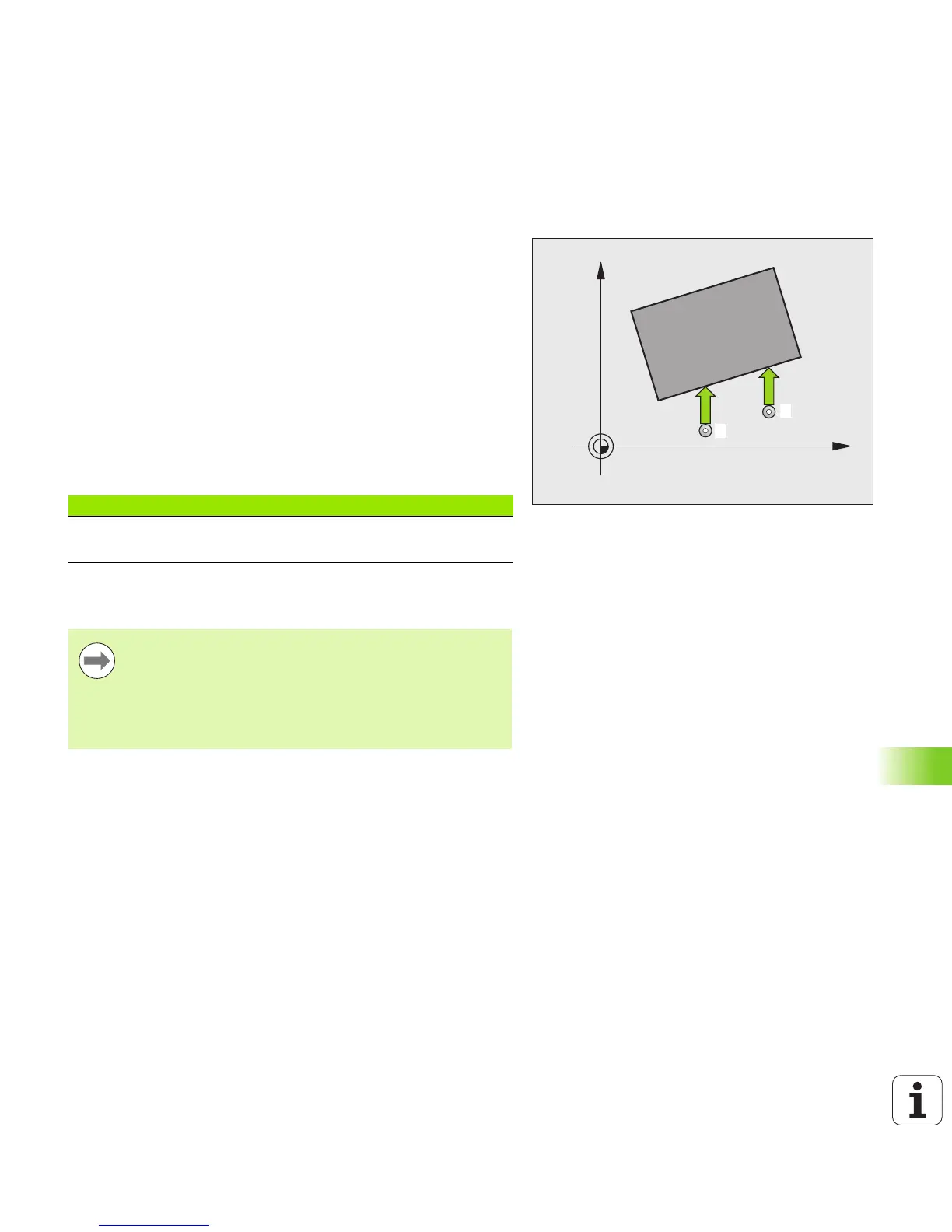

Touch Probe Cycle 420 measures the angle that any straight surface

on the workpiece describes with respect to the reference axis of the

working plane.

1 Following the positioning logic (see “Executing touch probe

cycles” on page 318), the TNC positions the touch probe to the

programmed probe starting point 1 at rapid traverse (value from

MP6150). The TNC offsets the touch probe by the safety clearance

in the direction opposite the defined traverse direction.

2 Then the touch probe moves to the entered measuring height and

probes the first touch point at the probing feed rate (MP6120).

3 Then the touch probe moves to the next starting position 2 and

probes the second position.

4 The TNC returns the touch probe to the clearance height and saves

the measured angle in the following Q parameter:

Please note while programming:

Parameter number Meaning

Q150 The measured angle is referenced to the

reference axis of the machining plane.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

If touch probe axis = measuring axis, set Q263 equal to

Q265 if the angle about the A axis is to be measured; set

Q263 not equal to Q265 if the angle is to be measured about

the B axis.

Loading...

Loading...