340 Touch Probe Cycles: Automatic Measurement of Workpiece Misalignment

14.7 Compensating Workpiece Misalignment by Rotating the C Axis (Cycle

405, DIN/ISO: G405)

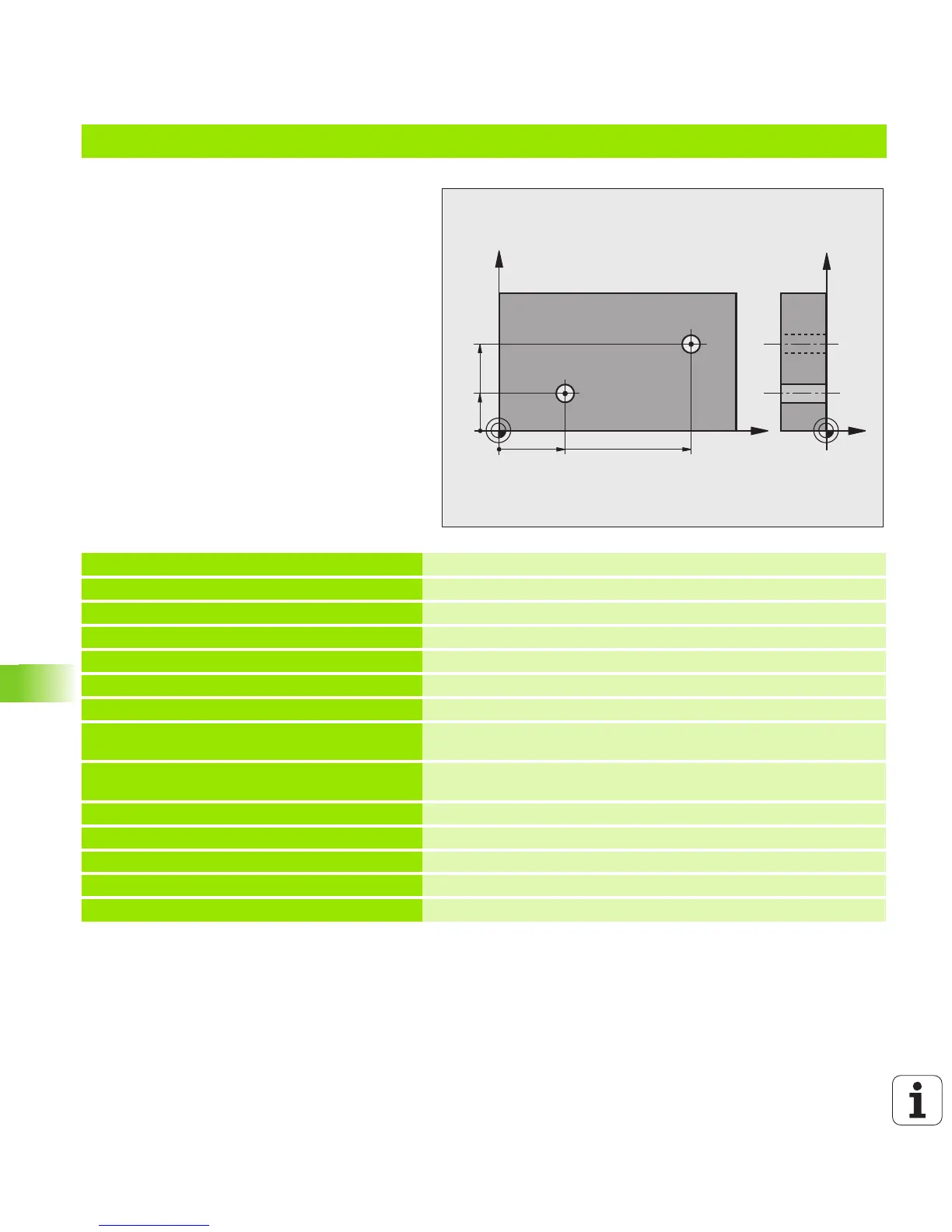

Example: Determining a basic rotation from two holes

0 BEGIN PGM CYC401 MM

1 TOOL CALL 69 Z

2 TCH PROBE 401 ROT 2 HOLES

Q268=+25 ;1ST CENTER IN 1ST AXIS

Center of the 1st hole: X coordinate

Q269=+15 ;1ST CENTER IN 2ND AXIS

Center of the 1st hole: Y coordinate

Q270=+80 ;2ND CENTER IN 1ST AXIS

Center of the 2nd hole: X coordinate

Q271=+35 ;2ND CENTER IN 2ND AXIS

Center of the 2nd hole: Y coordinate

Q261=-5 ;MEASURING HEIGHT

Coordinate in the touch probe axis in which the measurement is

made

Q260=+20 ;CLEARANCE HEIGHT

Height in the touch probe axis at which the probe can traverse

without collision

Q307=+0 ;PRESET BASIC ROTATION

Angle of the reference line

Q402=1 ;ALIGNMENT

Compensate misalignment by rotating the rotary table

Q337=1 ;SET TO ZERO

Set the display to zero after the alignment

3 CALL PGM 35K47

Part program call

4 END PGM CYC401 MM

Loading...

Loading...