HEIDENHAIN iTNC 530 339

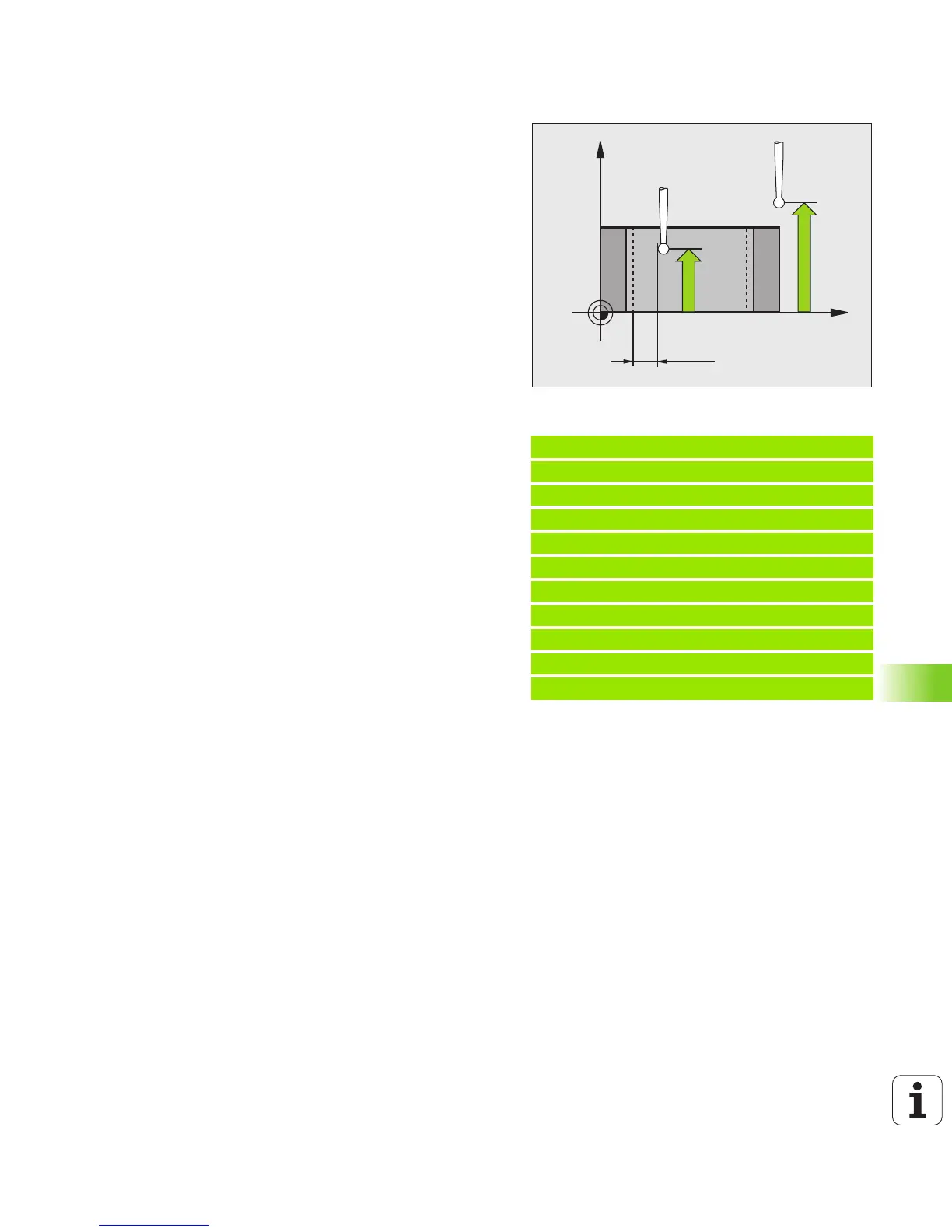

14.7 Compensating Workpiece Misalignment by Rotating the C Axis (Cycle

405, DIN/ISO: G405)

U Measuring height in the touch probe axis

Q261 (absolute): Coordinate of the ball tip

center (= touch point) in the touch probe axis in

which the measurement is to be made. Input

range -99999.9999 to 99999.9999

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

U Clearance height Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999, alternatively PREDEF

U Traversing to clearance height Q301: Definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1: Move at clearance height between measuring

points

Alternatively PREDEF

U Set to zero after alignment Q337: Definition of

whether the TNC should set the display of the C axis

to zero, or write the angular offset in column C of the

datum table:

0: Set display of C to 0

>0: Write the angular misalignment, including

algebraic sign, in the datum table. Line number =

value of Q337. If a C-axis shift is registered in the

datum table, the TNC adds the measured angular

misalignment.

Example: NC blocks

5 TCH PROBE 405 ROT IN C AXIS

Q321=+50 ;CENTER IN 1ST AXIS

Q322=+50 ;CENTER IN 2ND AXIS

Q262=10 ;NOMINAL DIAMETER

Q325=+0 ;STARTING ANGLE

Q247=90 ;STEPPING ANGLE

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SETUP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;MOVE TO CLEARANCE

Q337=0 ;SET TO ZERO

Loading...

Loading...