338 Touch Probe Cycles: Automatic Measurement of Workpiece Misalignment

14.7 Compensating Workpiece Misalignment by Rotating the C Axis (Cycle

405, DIN/ISO: G405)

Cycle parameters

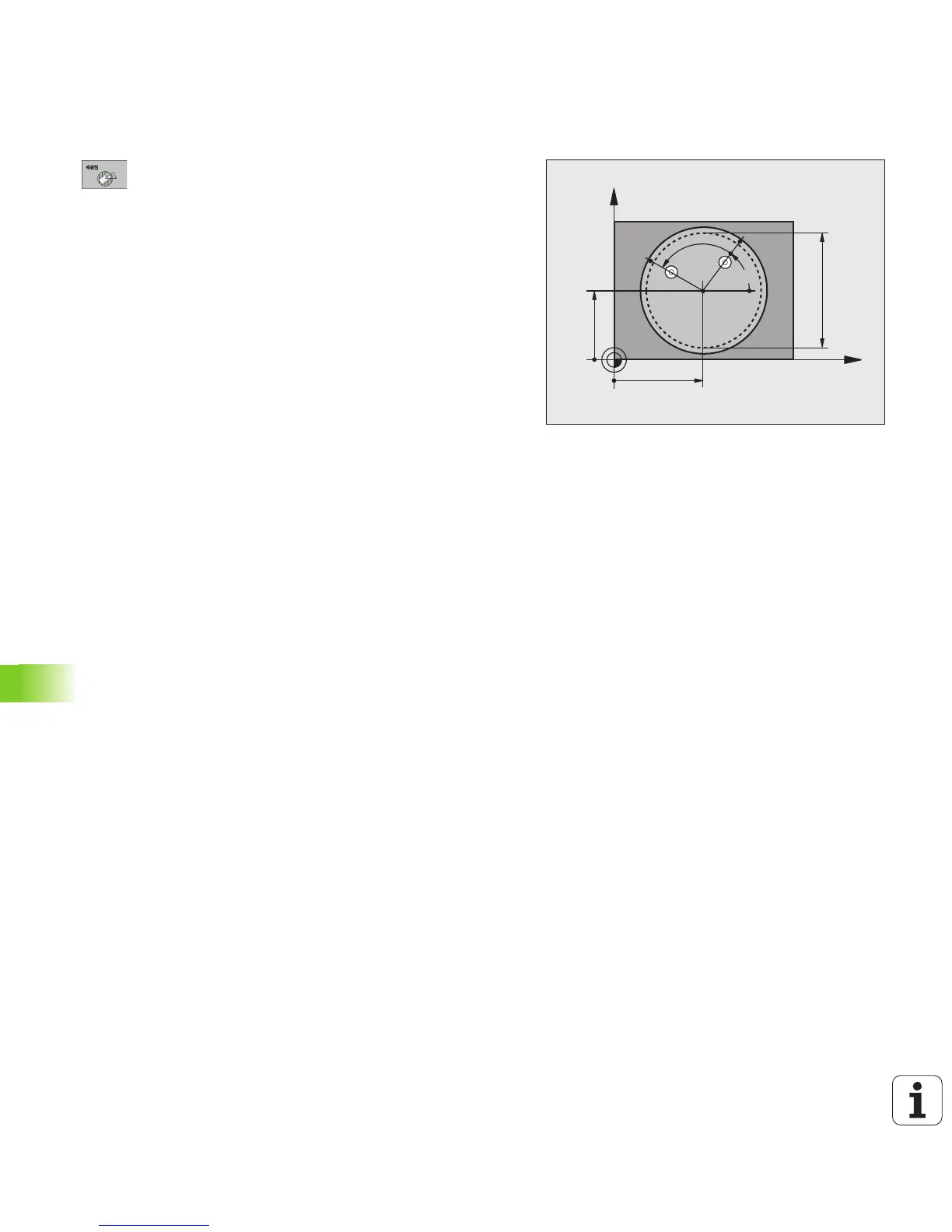

U Center in 1st axis Q321 (absolute): Center of the

hole in the reference axis of the working plane. Input

range -99999.9999 to 99999.9999

U Center in 2nd axis Q322 (absolute value): Center

of the hole in the minor axis of the working plane. If

you program Q322 = 0, the TNC aligns the hole

center to the positive Y axis. If you program Q322

not equal to 0, then the TNC aligns the hole center

to the nominal position (angle of the hole center).

Input range -99999.9999 to 99999.9999

U Nominal diameter Q262: Approximate diameter of the

circular pocket (or hole). Enter a value that is more

likely to be too small than too large. Input range 0 to

99999.9999

U Starting angle Q325 (absolute): Angle between the

reference axis of the working plane and the first touch

point. Input range -360.000 to 360.000

U Stepping angle Q247 (incremental): Angle between

two measuring points. The algebraic sign of the

stepping angle determines the direction of rotation

(negative = clockwise) in which the touch probe

moves to the next measuring point. If you wish to

probe a circular arc instead of a complete circle, then

program the stepping angle to be less than 90°. Input

range -120.000 to 120.000

Loading...

Loading...