HEIDENHAIN iTNC 530 315

13.2 Before You Start Working with Touch Probe Cycles

13.2 Before You Start Working with

Touch Probe Cycles

To make it possible to cover the widest possible range of applications,

machine parameters enable you to determine the behavior common

to all touch probe cycles.

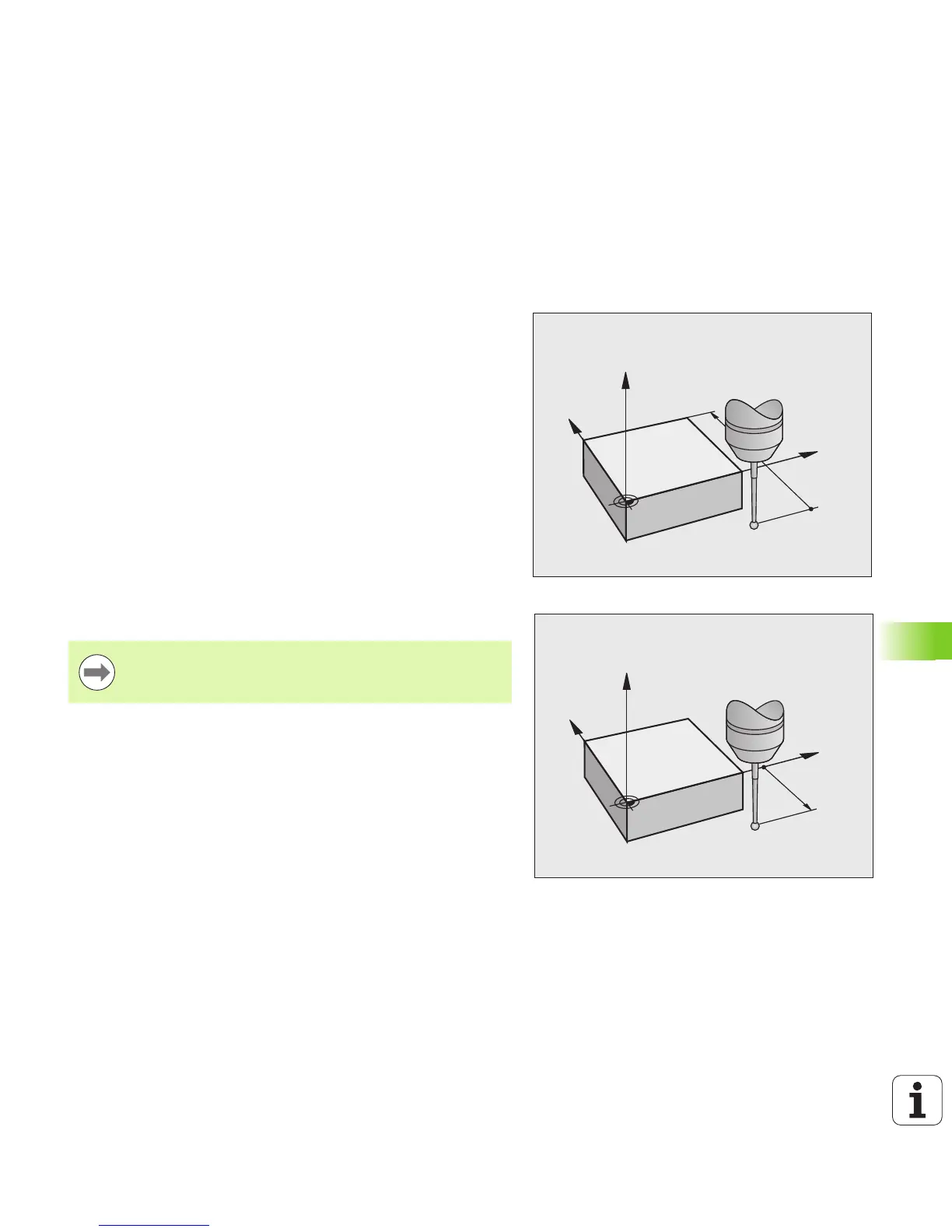

Maximum traverse to touch point: MP6130

If the stylus is not deflected within the path defined in MP6130, the

TNC outputs an error message.

Safety clearance to touch point: MP6140

In MP6140 you define how far from the defined (or calculated) touch

point the TNC is to pre-position the touch probe. The smaller the value

you enter, the more exactly must you define the touch point position.

In many touch probe cycles you can also define a setup clearance in

addition that is added to Machine Parameter 6140.

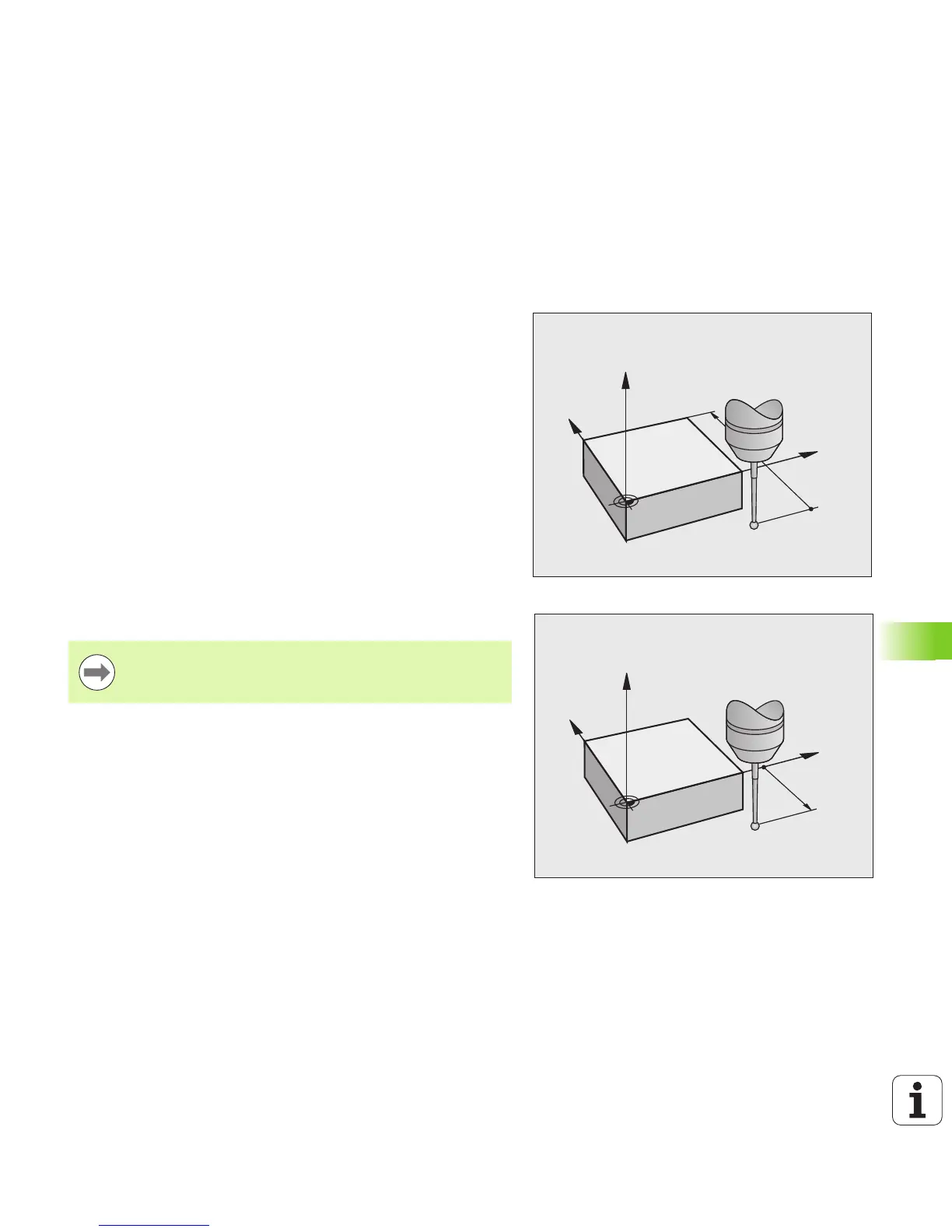

Orient the infrared touch probe to the

programmed probe direction: MP6165

To increase measuring accuracy, you can use MP 6165 = 1 to have an

infrared touch probe oriented in the programmed probe direction

before every probe process. In this way the stylus is always deflected

in the same direction.

If you change MP6165, you must recalibrate the touch

probe, because its deflection behavior changes.

Loading...

Loading...