430 Touch Probe Cycles: Automatic Workpiece Inspection

16.11 MEASURE COORDINATE (Cycle 427, DIN/ISO: G427)

16.11 MEASURE COORDINATE

(Cycle 427, DIN/ISO: G427)

Cycle run

Touch probe cycle 427 finds a coordinate in a selectable axis and saves

the value in a system parameter. If you define the corresponding

tolerance values in the cycle, the TNC makes a nominal-to-actual value

comparison and saves the deviation value in system parameters.

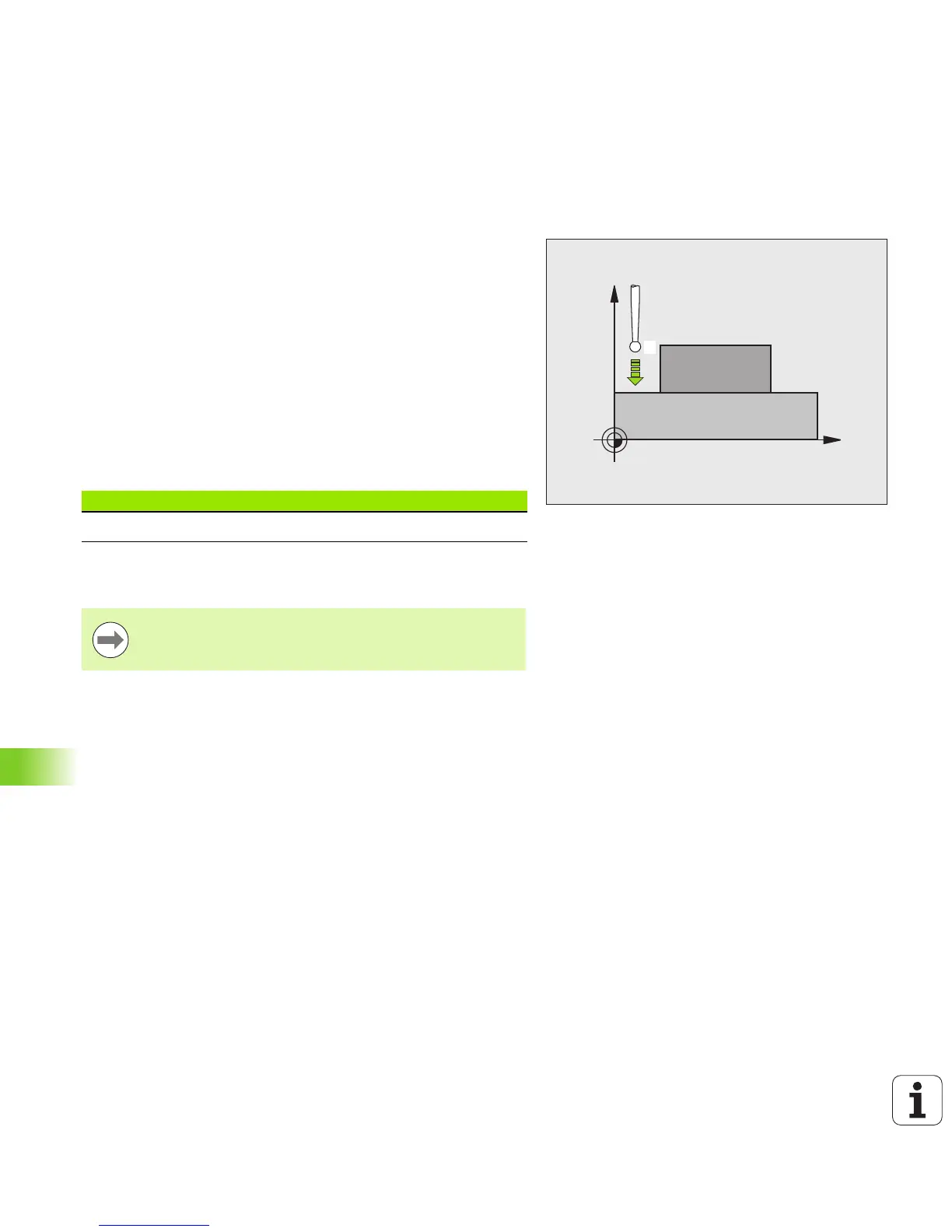

1 Following the positioning logic (see “Executing touch probe

cycles” on page 318), the TNC positions the touch probe to the

probe starting point 1 at rapid traverse (value from MP6150). The

TNC offsets the touch probe by the safety clearance in the

direction opposite the defined traverse direction.

2 Then the TNC positions the touch probe to the entered touch point

1 in the working plane and measures the actual value in the

selected axis.

3 Finally the TNC returns the touch probe to the clearance height and

saves the measured coordinate in the following Q parameter:

Please note while programming:

Loading...

Loading...