HEIDENHAIN iTNC 530 127

4.8 THREAD DRILLING/MILLING (Cycle 264, DIN/ISO: G264)

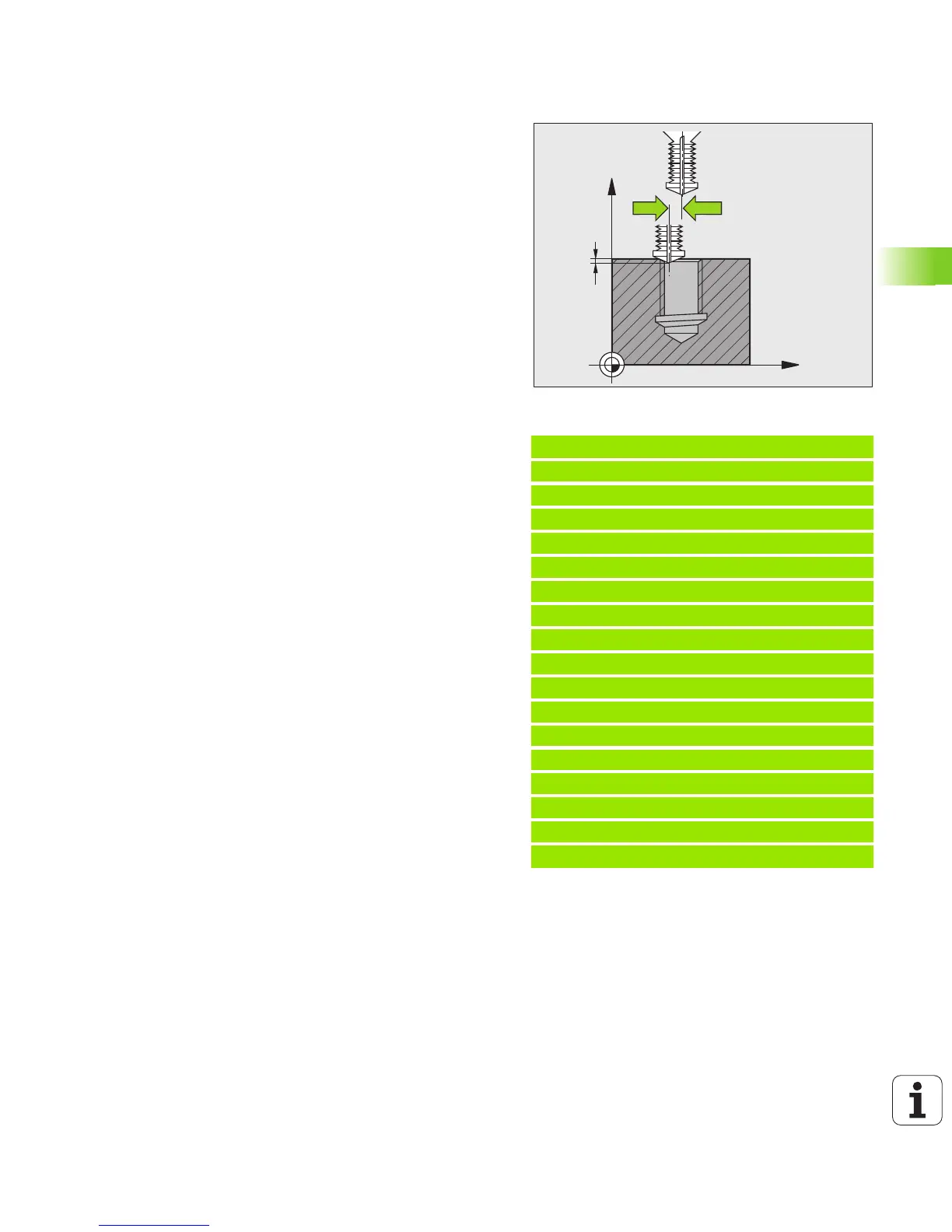

U Depth at front Q358 (incremental): Distance

between tool tip and the top surface of the workpiece

for countersinking at the front of the tool. Input range

-99999.9999 to 99999.9999

U Countersinking offset at front Q359 (incremental):

Distance by which the TNC moves the tool center

away from the hole center. Input range 0 to

99999.9999

U Setup clearance Q200 (incremental): Distance

between tool tip and workpiece surface. Input range

0 to 99999.9999, alternatively PREDEF

U Workpiece surface coordinate Q203 (absolute):

Coordinate of the workpiece surface. Input range:

-99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

U Feed rate for plunging Q206: Traversing speed of

the tool during drilling in mm/min. Input range: 0 to

99999.999; alternatively FAUTO, FU.

U Feed rate for milling Q207: Traversing speed of the

tool during milling in mm/min. Input range: 0 to

99999.9999, alternatively FAUTO.

Example: NC blocks

25 CYCL DEF 264 THREAD DRILLNG/MLLNG

Q335=10 ;NOMINAL DIAMETER

Q239=+1.5 ;PITCH

Q201=-16 ;DEPTH OF THREAD

Q356=-20 ;TOTAL HOLE DEPTH

Q253=750 ;F PRE-POSITIONING

Q351=+1 ;CLIMB OR UP-CUT

Q202=5 ;PLUNGING DEPTH

Q258=0.2 ;ADVANCED STOP DISTANCE

Q257=5 ;DEPTH FOR CHIP BRKNG

Q256=0.2 ;DIST. FOR CHIP BRKNG

Q358=+0 ;DEPTH AT FRONT

Q359=+0 ;OFFSET AT FRONT

Q200=2 ;SETUP CLEARANCE

Q203=+30 ;SURFACE COORDINATE

Q204=50 ;2ND SETUP CLEARANCE

Q206=150 ;FEED RATE FOR PLNGNG

Q207=500 ;FEED RATE FOR MILLING

Loading...

Loading...