HEIDENHAIN iTNC 530 175

6.2 CIRCULAR PATTERN (Cycle 220, DIN/ISO: G220)

U Setup clearance Q200 (incremental): Distance

between tool tip and workpiece surface. Input range

0 to 99999.9999, alternatively PREDEF

U Workpiece surface coordinate Q203 (absolute):

Coordinate of the workpiece surface. Input range:

-99999.9999 to 99999.9999

U 2nd setup clearance Q204 (incremental): Coordinate

in the spindle axis at which no collision between tool

and workpiece (fixtures) can occur. Input range 0 to

99999.9999, alternatively PREDEF

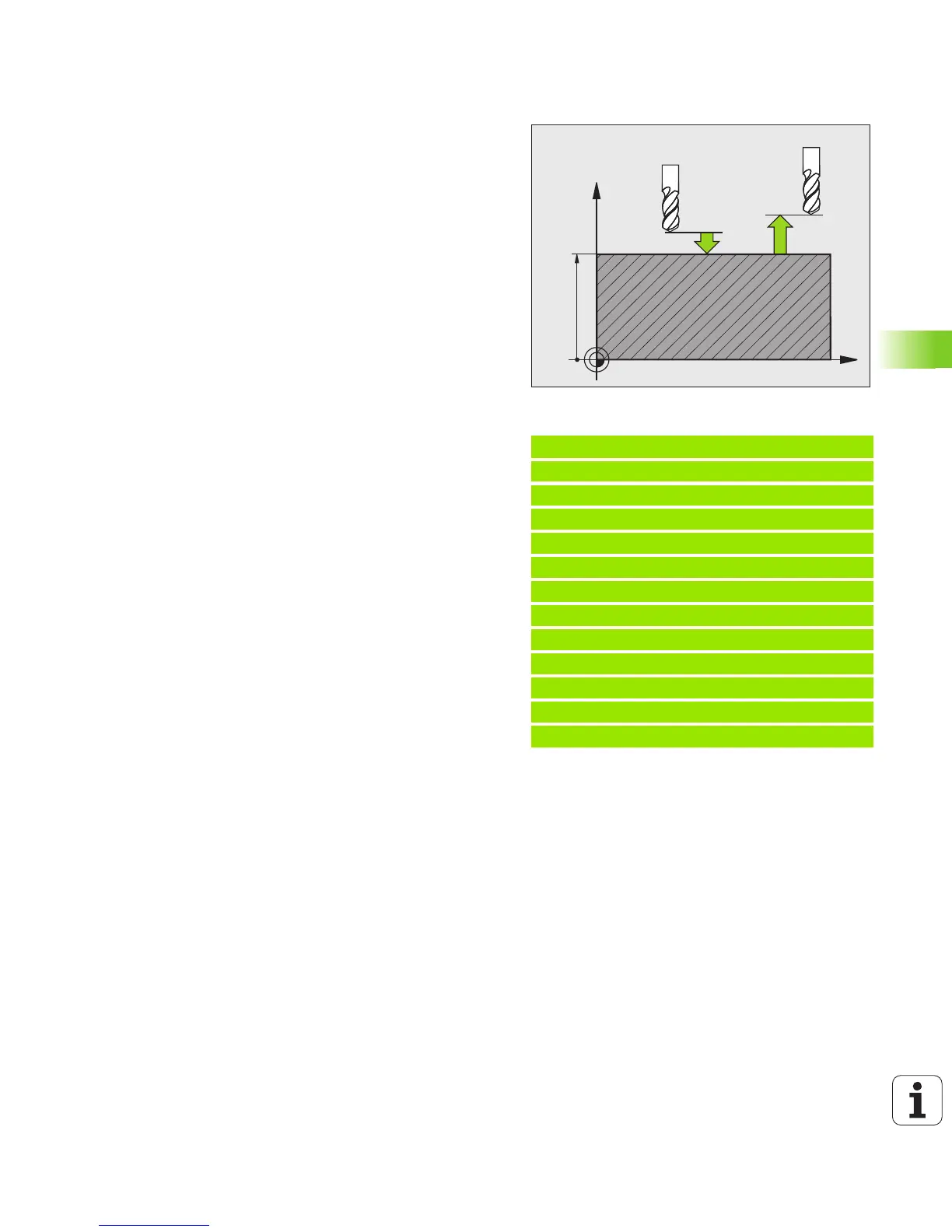

U Moving to clearance height Q301: Definition of how

the tool is to move between machining processes.

0: Move to the setup clearance between operations.

1: Move to the 2nd setup clearance between

machining operations.

Alternatively PREDEF

U Type of traverse? Line=0/Arc=1 Q365: Definition of

the path function with which the tool is to move

between machining operations.

0: Move between operations on a straight line

1: Move between operations on the pitch circle

Example: NC blocks

53 CYCLE DEF 220 POLAR PATTERN

Q216=+50 ;CENTER IN 1ST AXIS

Q217=+50 ;CENTER 2ND AXIS

Q244=80 ;PITCH CIRCLE DIA.

Q245=+0 ;STARTING ANGLE

Q246=+360 ;STOPPING ANGLE

Q247=+0 ;STEPPING ANGLE

Q241=8 ;NUMBER OF OPERATIONS

Q200=2 ;SETUP CLEARANCE

Q203=+30 ;SURFACE COORDINATE

Q204=50 ;2ND SETUP CLEARANCE

Q301=1 ;MOVE TO CLEARANCE

Q365=0 ;TYPE OF TRAVERSE

Loading...

Loading...