HEIDENHAIN iTNC 530 191

7.4 CONTOUR DATA (Cycle 20, DIN/ISO: G120)

Cycle parameters

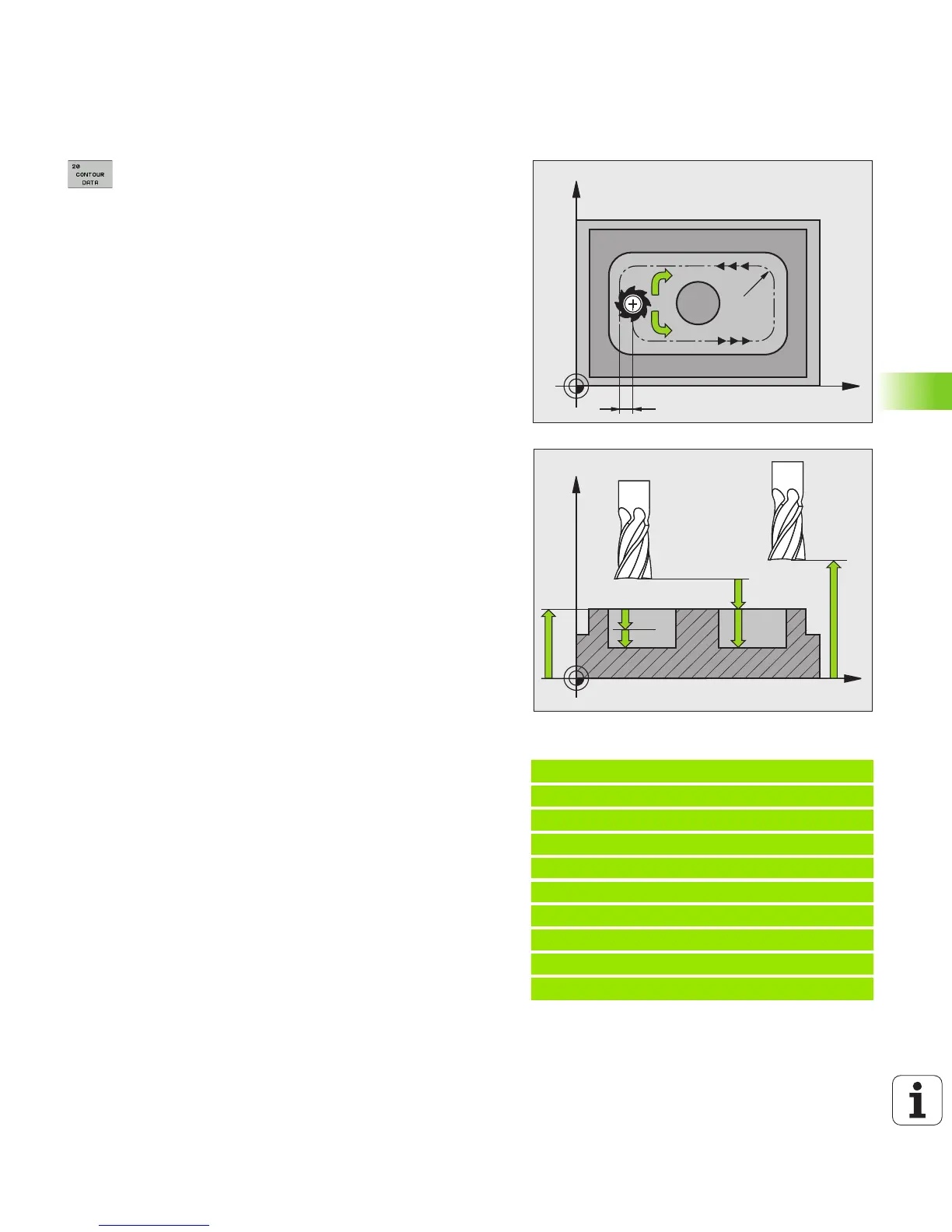

U Milling depth Q1 (incremental): Distance between

workpiece surface and bottom of pocket. Input range

-99999.9999 to 99999.9999

U Path overlap factor Q2: Q2 x tool radius = stepover

factor k. Input range -0.0001 to 1.9999.

U Finishing allowance for side Q3 (incremental):

Finishing allowance in the working plane. Input range:

-99999.9999 to 99999.9999

U Finishing allowance for floor Q4

(incremental): Finishing allowance in the tool axis.

Input range -99999.9999 to 99999.9999

U Workpiece surface coordinate Q5 (absolute):

Absolute coordinate of the workpiece surface. Input

range -99999.9999 to 99999.9999

U Setup clearance Q6 (incremental): Distance between

tool tip and workpiece surface. Input range 0 to

99999.9999, alternatively PREDEF

U Clearance height Q7 (absolute): Absolute height at

which the tool cannot collide with the workpiece (for

intermediate positioning and retraction at the end of

the cycle). Input range -99999.9999 to 99999.9999,

alternatively PREDEF

U Inside corner radius Q8: Inside “corner” rounding

radius; entered value is referenced to the path of the

tool center. Q8 is not a radius that is inserted as a

separate contour element between programmed

elements! Input range 0 to 99999.9999

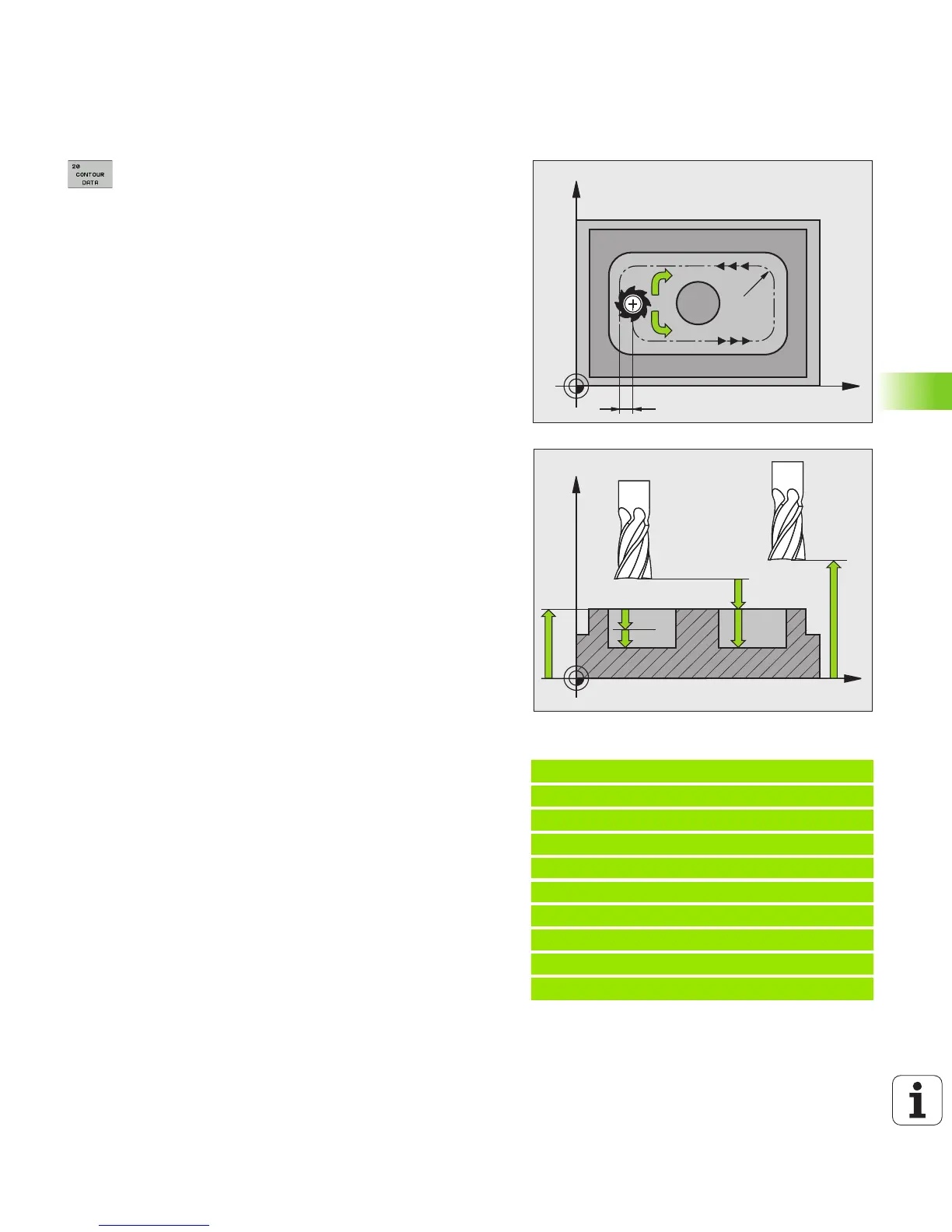

U Direction of rotation? Q9: Machining direction for

pockets.

Q9 = –1 up-cut milling for pocket and island

Q9 = +1 climb milling for pocket and island

Alternative: PREDEF

You can check the machining parameters during a program

interruption and overwrite them if required.

Example: NC blocks

57 CYCL DEF 20 CONTOUR DATA

Q1=-20 ;MILLING DEPTH

Q2=1 ;TOOL PATH OVERLAP

Q3=+0.2 ;ALLOWANCE FOR SIDE

Q4=+0.1 ;ALLOWANCE FOR FLOOR

Q5=+30 ;SURFACE COORDINATE

Q6=2 ;SETUP CLEARANCE

Q7=+80 ;CLEARANCE HEIGHT

Q8=0.5 ;ROUNDING RADIUS

Q9=+1 ;DIRECTION

Loading...

Loading...