200 Fixed Cycles: Contour Pocket, Contour Trains

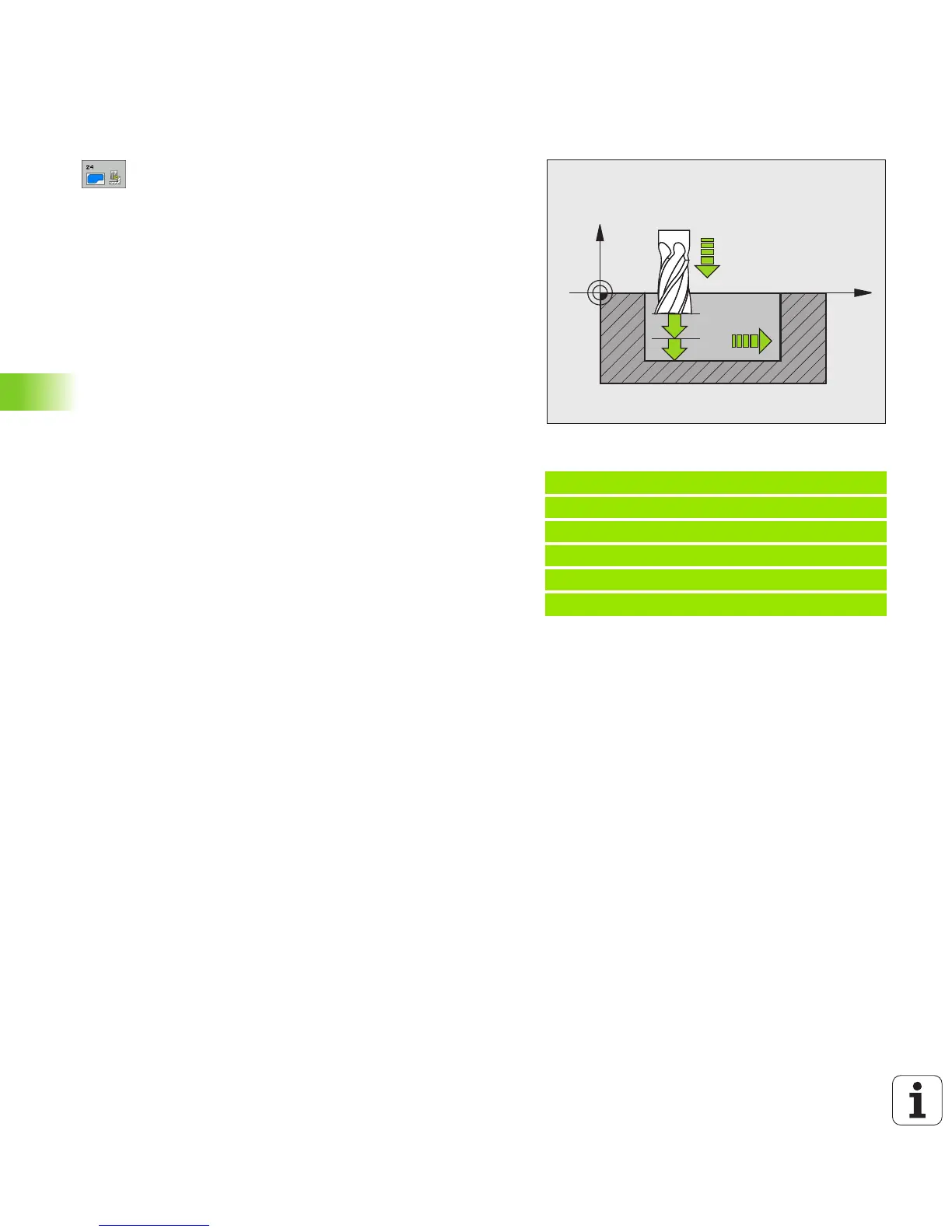

7.8 SIDE FINISHING (Cycle 24, DIN/ISO: G124)

Cycle parameters

U Direction of rotation? Clockwise = –1 Q9:

Machining direction:

+1:Counterclockwise

–1:Clockwise

Alternatively PREDEF

U Plunging depth Q10 (incremental): Infeed per cut.

Input range: -99999.9999 to 99999.9999

U Feed rate for plunging Q11: Traversing speed of the

tool during plunging. Input range 0 to 99999.9999,

alternatively FAUTO, FU, FZ

U Feed rate for roughing Q12: Milling feed rate. Input

range 0 to 99999.9999, alternatively FAUTO, FU, FZ

U Finishing allowance for side Q14

(incremental): Enter the allowed material for

several finish-milling operations. If you enter

Q14 = 0, the remaining finishing allowance will

be cleared. Input range -99999.9999 to

99999.9999

Example: NC blocks

61 CYCLE DEF 24 SIDE FINISHING

Q9=+1 ;DIRECTION

Q10=+5 ;PLUNGING DEPTH

Q11=100 ;FEED RATE FOR PLNGNG

Q12=350 ;FEED RATE FOR ROUGHING

Q14=+0 ;ALLOWANCE FOR SIDE

Loading...

Loading...