256 Fixed Cycles: Multipass Milling

10.2 RUN 3-D DATA (Cycle 30, DIN/ISO: G60)

Cycle parameters

U PGM name 3-D data: Enter the name of the program in

which the contour data is stored. If the file is not

stored in the current directory, enter the complete

path. A maximum of 254 characters can be entered.

U Min. point of range: Lowest coordinates (X, Y and

Z coordinates) in the range to be milled. Input range

-99999.9999 to 99999.9999

U Max. point of range: Largest coordinates (X, Y and

Z coordinates) in the range to be milled. Input range

-99999.9999 to 99999.9999

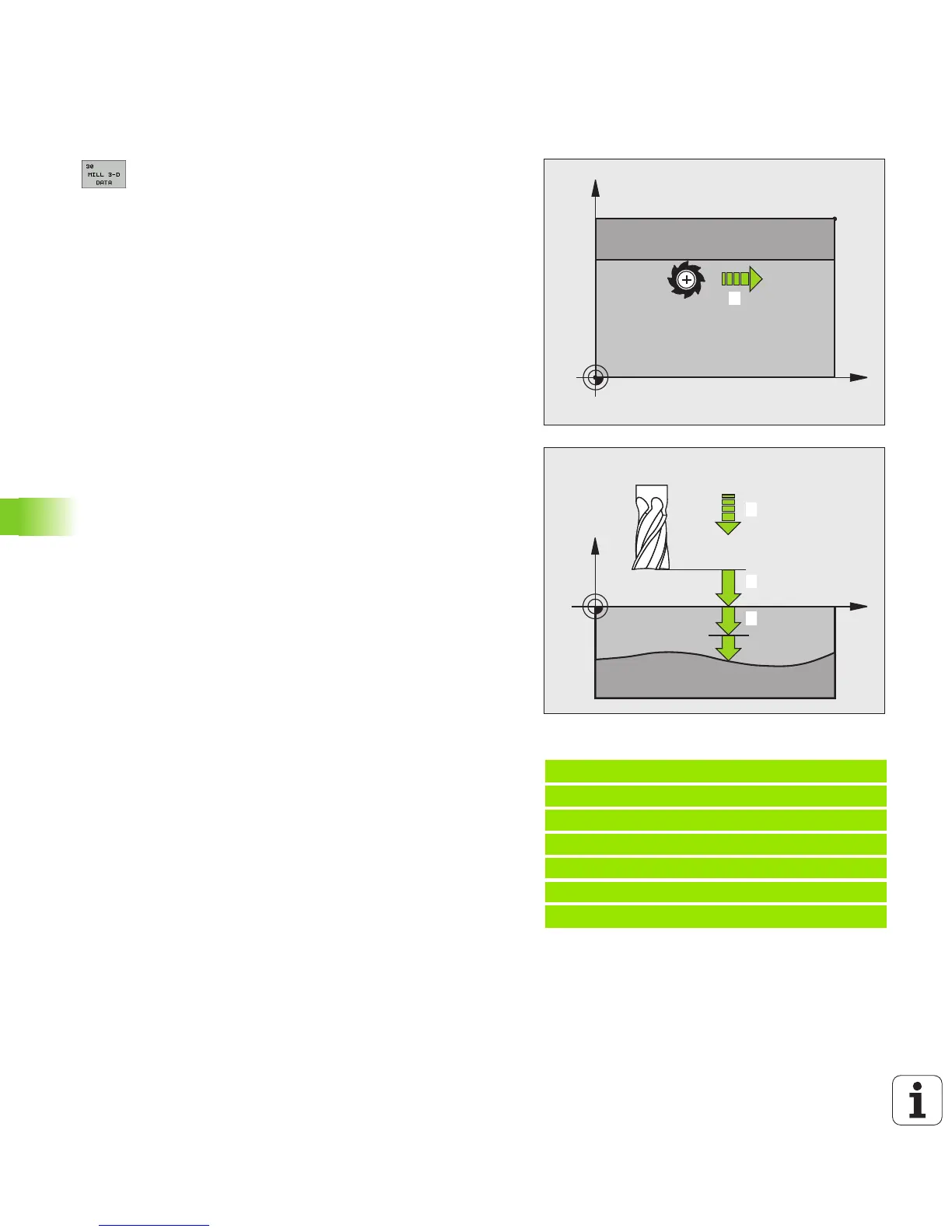

U Setup clearance 1 (incremental): Distance between

tool tip and workpiece surface for tool movements at

rapid traverse. Input range 0 to 99999.9999

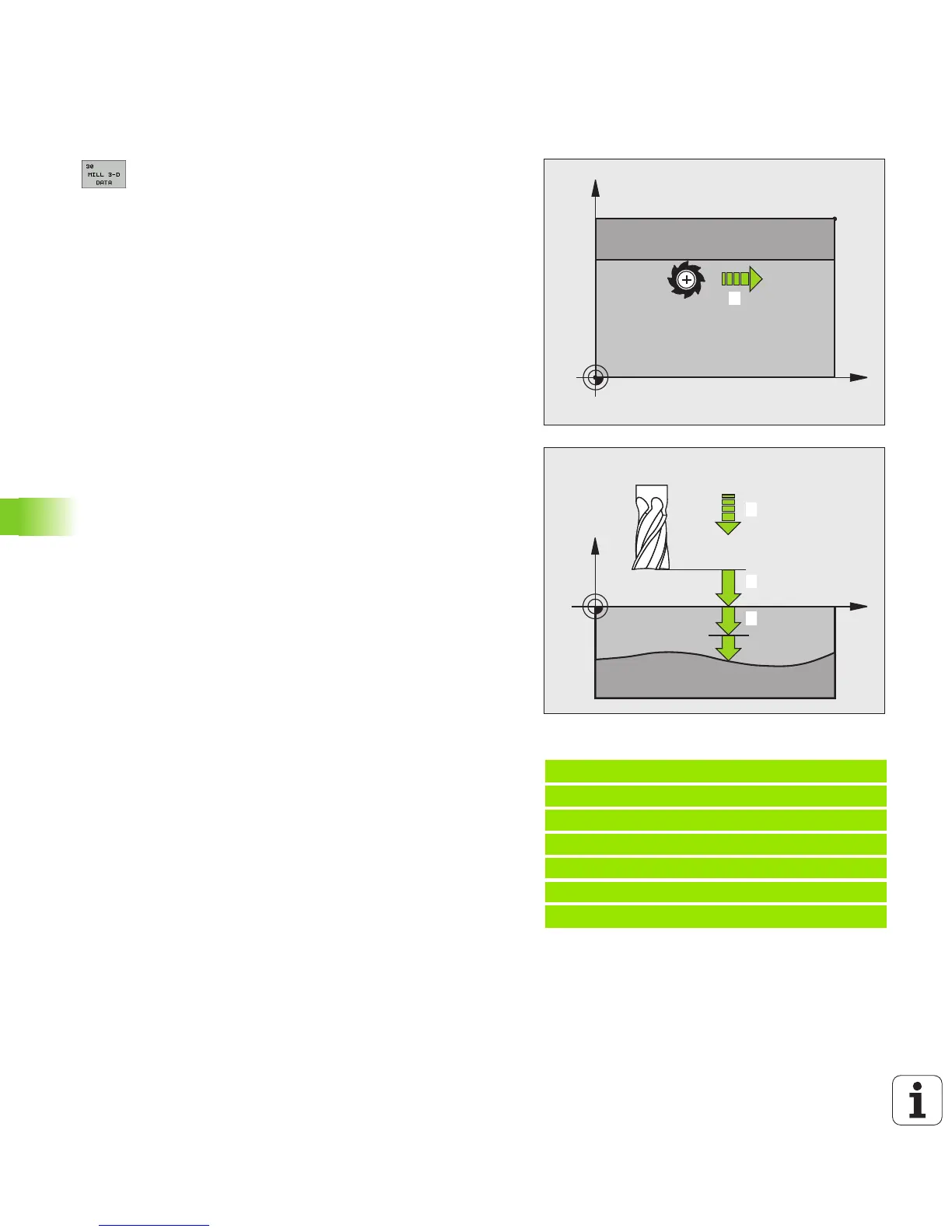

U Plunging depth 2 (incremental value): Infeed per cut

Input range: -99999.9999 to 99999.9999

U Feed rate for plunging 3: Traversing speed of the

tool during plunging in mm/min. Input range: 0 to

99999.999; alternatively FAUTO.

U Feed rate for plunging 4: Traversing speed of the

tool during milling in mm/min. Input range: 0 to

99999.9999; alternatively FAUTO.

U Miscellaneous function M: Optional entry of one to

two miscellaneous functions, for example M13. Input

range 0 to 999

Example: NC blocks

64 CYCL DEF 30.0 RUN 3-D DATA

65 CYCL DEF 30.1 PGM DIGIT.: BSP.H

66 CYCL DEF 30.2 X+0 Y+0 Z-20

67 CYCL DEF 30.3 X+100 Y+100 Z+0

68 CYCL DEF 30.4 SETUP 2

69 CYCL DEF 30.5 PECKG -5 F100

70 CYCL DEF 30.6 F350 M8

Loading...

Loading...