HEIDENHAIN iTNC 530 333

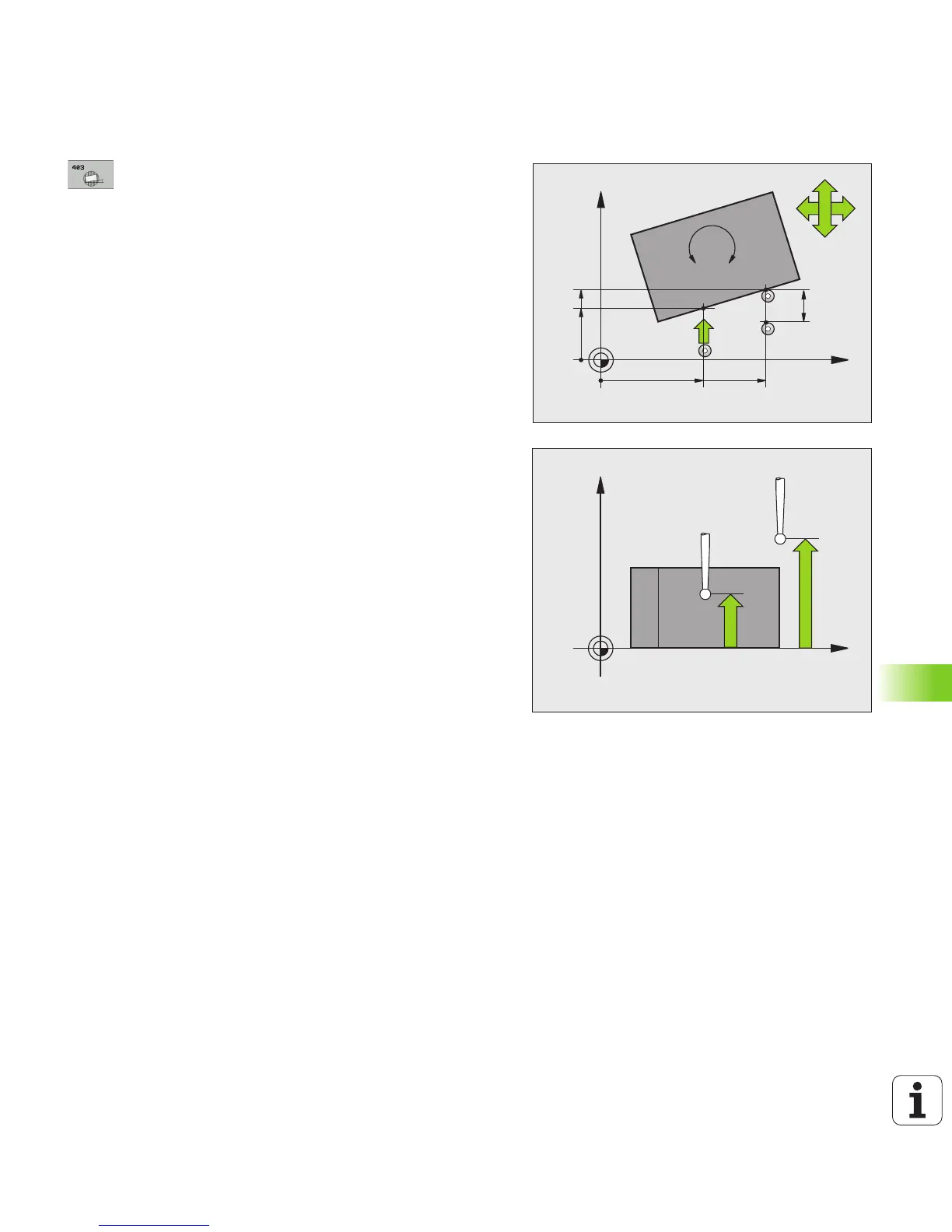

14.5 BASIC ROTATION Compensation via Rotary Axis (Cycle 403, DIN/ISO:

G403)

Cycle parameters

U 1st meas. point 1st axis Q263 (absolute):

Coordinate of the first touch point in the reference

axis of the working plane. Input range -99999.9999 to

99999.9999

U 1st meas. point 2nd axis Q264 (absolute):

Coordinate of the first touch point in the minor axis of

the working plane. Input range -99999.9999 to

99999.9999

U 2nd meas. point 1st axis Q265 (absolute):

Coordinate of the second touch point in the reference

axis of the working plane. Input range -99999.9999 to

99999.9999

U 2nd meas. point 2nd axis Q266 (absolute):

Coordinate of the second touch point in the minor axis

of the working plane. Input range -99999.9999 to

99999.9999

U Measuring axis Q272: Axis in which the

measurement is to be made:

1: Reference axis = measuring axis

2: Minor axis = measuring axis

3: Touch probe axis = measuring axis

U Traverse direction 1 Q267: Direction in which the

probe is to approach the workpiece:

-1: Negative traverse direction

+1: Positive traverse direction

U Measuring height in the touch probe axis

Q261 (absolute): Coordinate of the ball tip

center (= touch point) in the touch probe axis in

which the measurement is to be made. Input

range -99999.9999 to 99999.9999

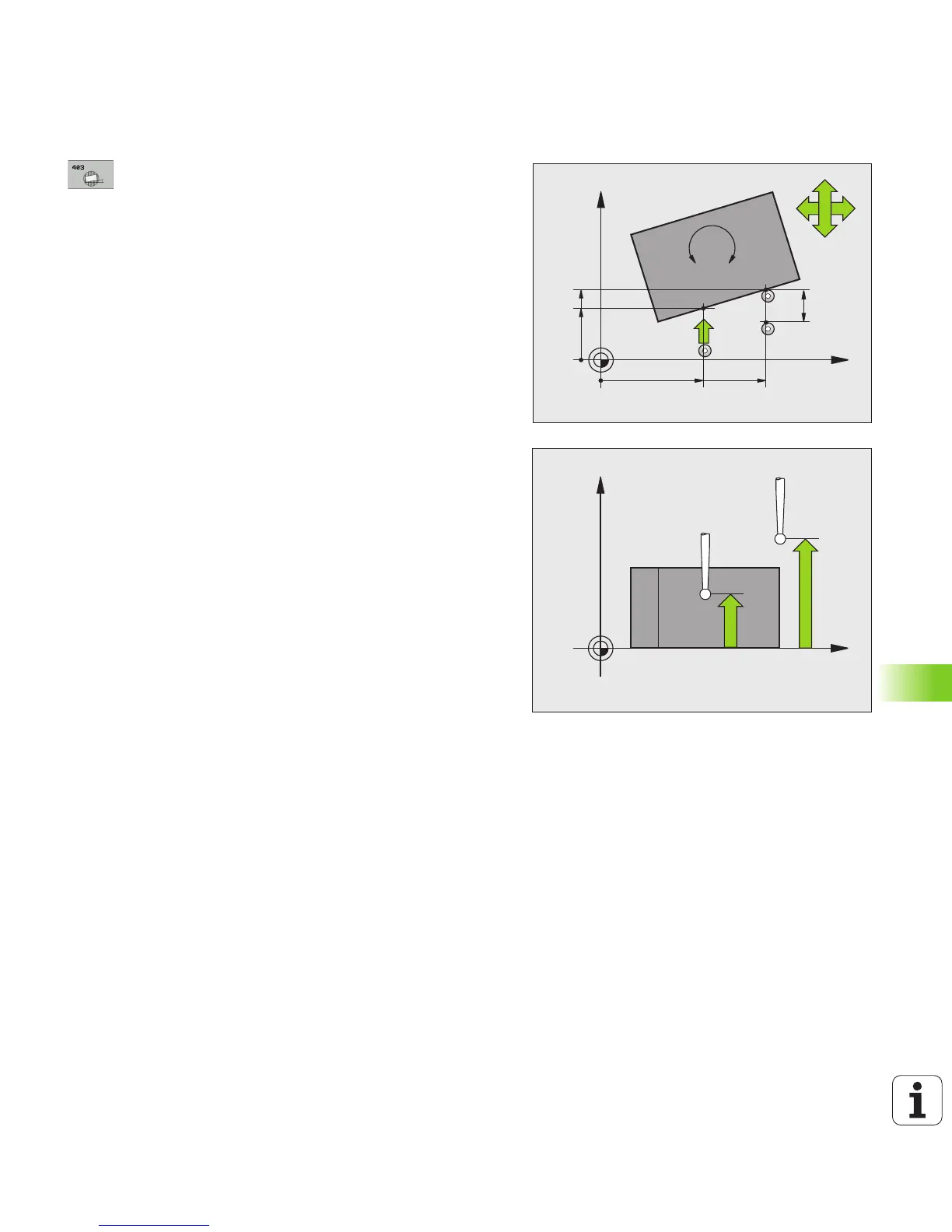

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

Loading...

Loading...