HEIDENHAIN iTNC 530 357

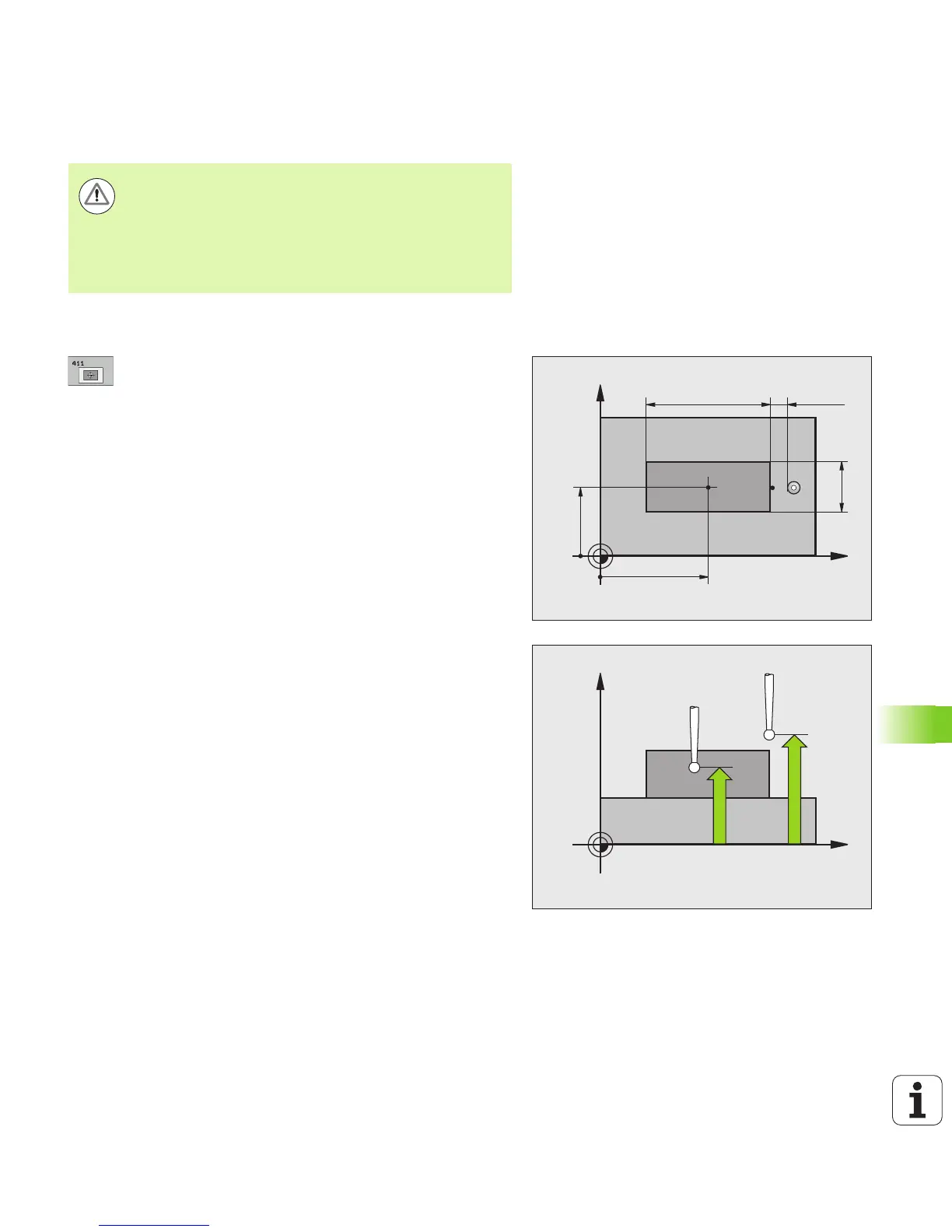

15.5 DATUM FROM OUTSIDE OF RECTANGLE (Cycle 411, DIN/ISO: G411)

Please note while programming:

Cycle parameters

U Center in 1st axis Q321 (absolute): Center of the

stud in the reference axis of the working plane. Input

range -99999.9999 to 99999.9999

U Center in 2nd axis Q322 (absolute): Center of the

stud in the minor axis of the working plane. Input

range -99999.9999 to 99999.9999

U First side length Q323 (incremental): Stud length,

parallel to the reference axis of the working plane

Input range 0 to 99999.9999

U 2nd side length Q324 (incremental): Stud length,

parallel to the minor axis of the working plane. Input

range 0 to 99999.9999

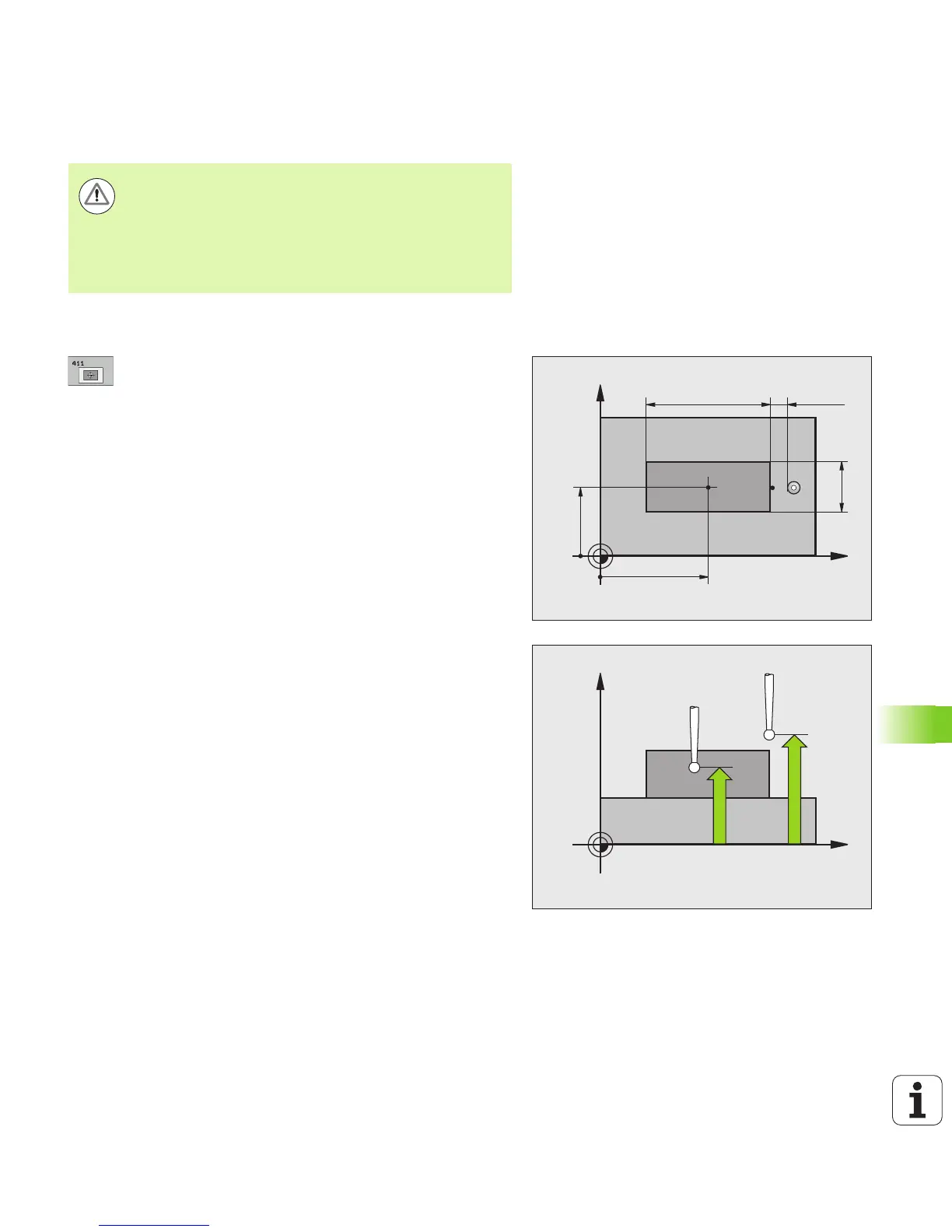

U Measuring height in the touch probe axis

Q261 (absolute): Coordinate of the ball tip

center (= touch point) in the touch probe axis in

which the measurement is to be made. Input

range -99999.9999 to 99999.9999

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

U Clearance height Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999, alternatively PREDEF

Danger of collision!

To prevent a collision between the touch probe and

workpiece, enter high estimates for the lengths of the 1st

and 2nd sides.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

Loading...

Loading...