HEIDENHAIN iTNC 530 365

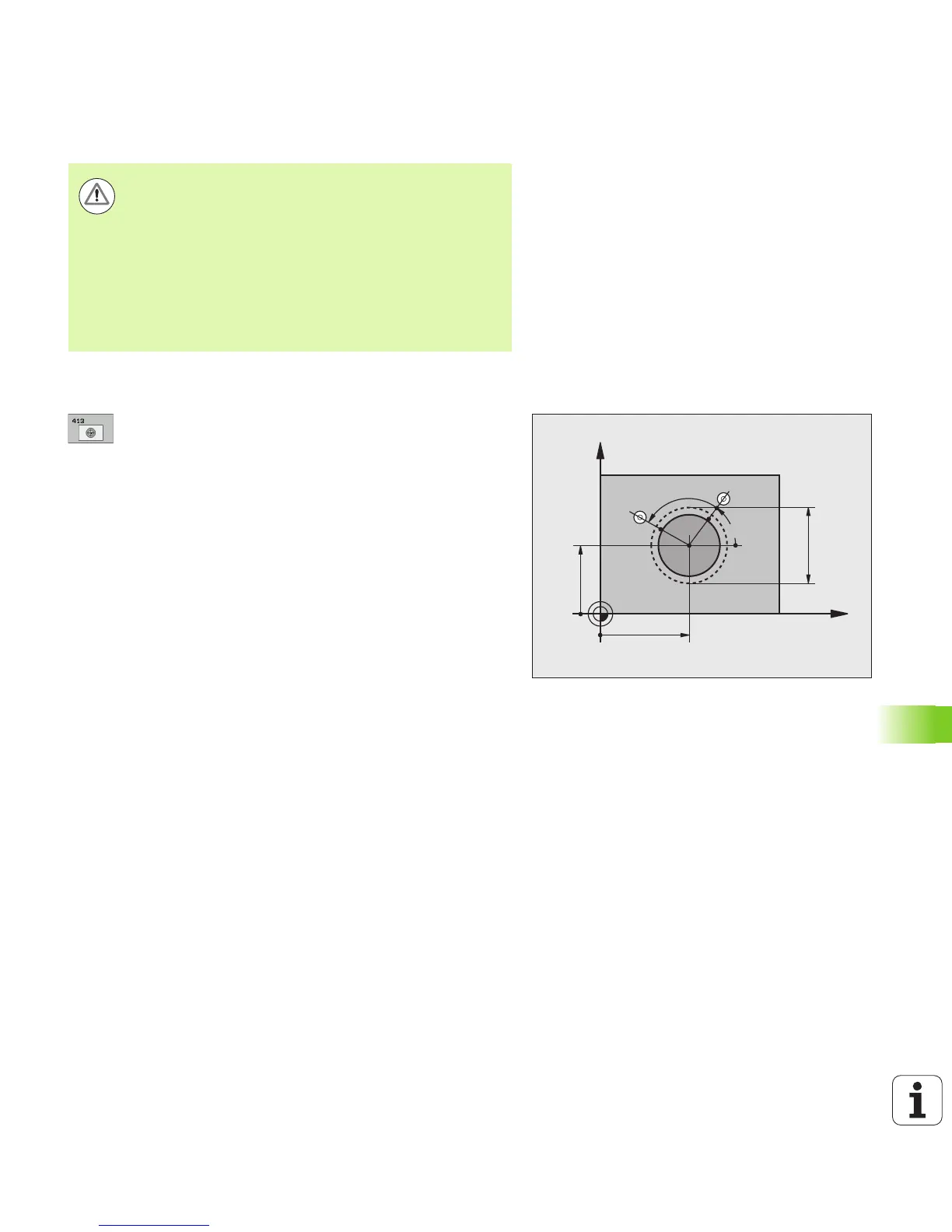

15.7 DATUM FROM OUTSIDE OF CIRCLE (Cycle 413, DIN/ISO: G413)

Please note while programming:

Cycle parameters

U Center in 1st axis Q321 (absolute): Center of the

stud in the reference axis of the working plane. Input

range -99999.9999 to 99999.9999

U Center in 2nd axis Q322 (absolute): Center of the

stud in the minor axis of the working plane. If you

program Q322 = 0, the TNC aligns the hole center to

the positive Y axis. If you program Q322 not equal to

0, then the TNC aligns the hole center to the nominal

position. Input range -99999.9999 to 99999.9999

U Nominal diameter Q262: Approximate diameter of the

stud. Enter a value that is more likely to be too large

than too small. Input range 0 to 99999.9999

U Starting angle Q325 (absolute): Angle between the

reference axis of the working plane and the first touch

point. Input range -360.0000 to 360.0000

U Stepping angle Q247 (incremental): Angle

between two measuring points. The algebraic sign

of the stepping angle determines the direction of

rotation (- = clockwise) in which the touch probe

moves to the next measuring point. If you wish to

probe a circular arc instead of a complete circle,

then program the stepping angle to be less than

90°. Input range -120.0000 to 120.0000

Danger of collision!

To prevent a collision between touch probe and

workpiece, enter a high estimate for the nominal diameter

of the stud.

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The smaller the angle increment Q247, the less

accurately the TNC can calculate the datum. Minimum

input value: 5°.

Loading...

Loading...