374 Touch Probe Cycles: Automatic Datum Setting

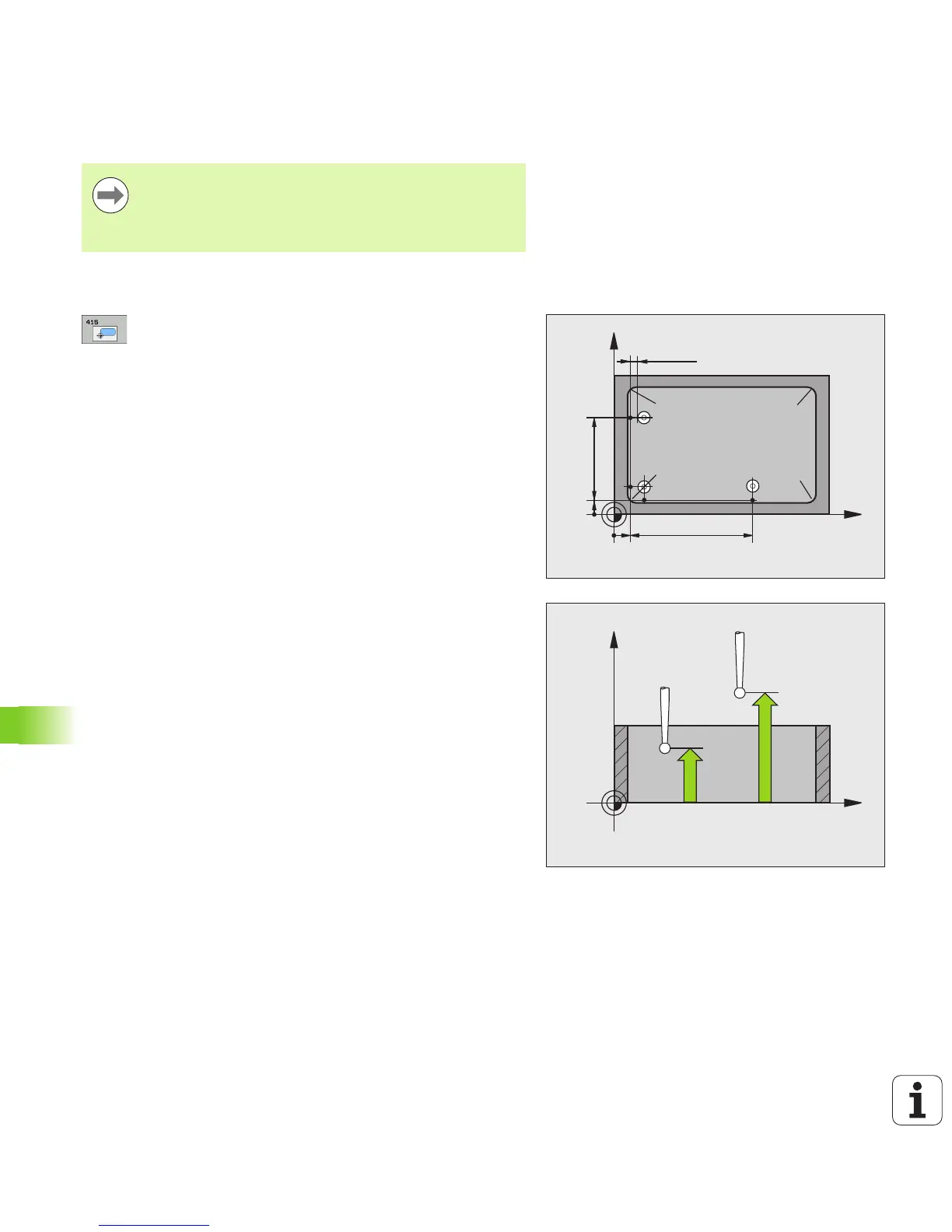

15.9 DATUM FROM INSIDE OF CORNER (Cycle 415, DIN/ISO: G415)

Please note while programming:

Cycle parameters

U 1st meas. point 1st axis Q263 (absolute):

Coordinate of the first touch point in the reference

axis of the working plane. Input range -99999.9999 to

99999.9999

U 1st meas. point 2nd axis Q264 (absolute):

Coordinate of the first touch point in the minor axis of

the working plane. Input range -99999.9999 to

99999.9999

U Spacing in 1st axis Q326 (incremental): Distance

between the first and second measuring points in the

reference axis of the working plane. Input range 0 to

99999.9999

U Spacing in 2nd axis Q327 (incremental): Distance

between third and fourth measuring points in the

minor axis of the working plane. Input range 0 to

99999.9999

U Corner Q308: Number identifying the corner which

the TNC is to set as datum. Input range 1 to 4

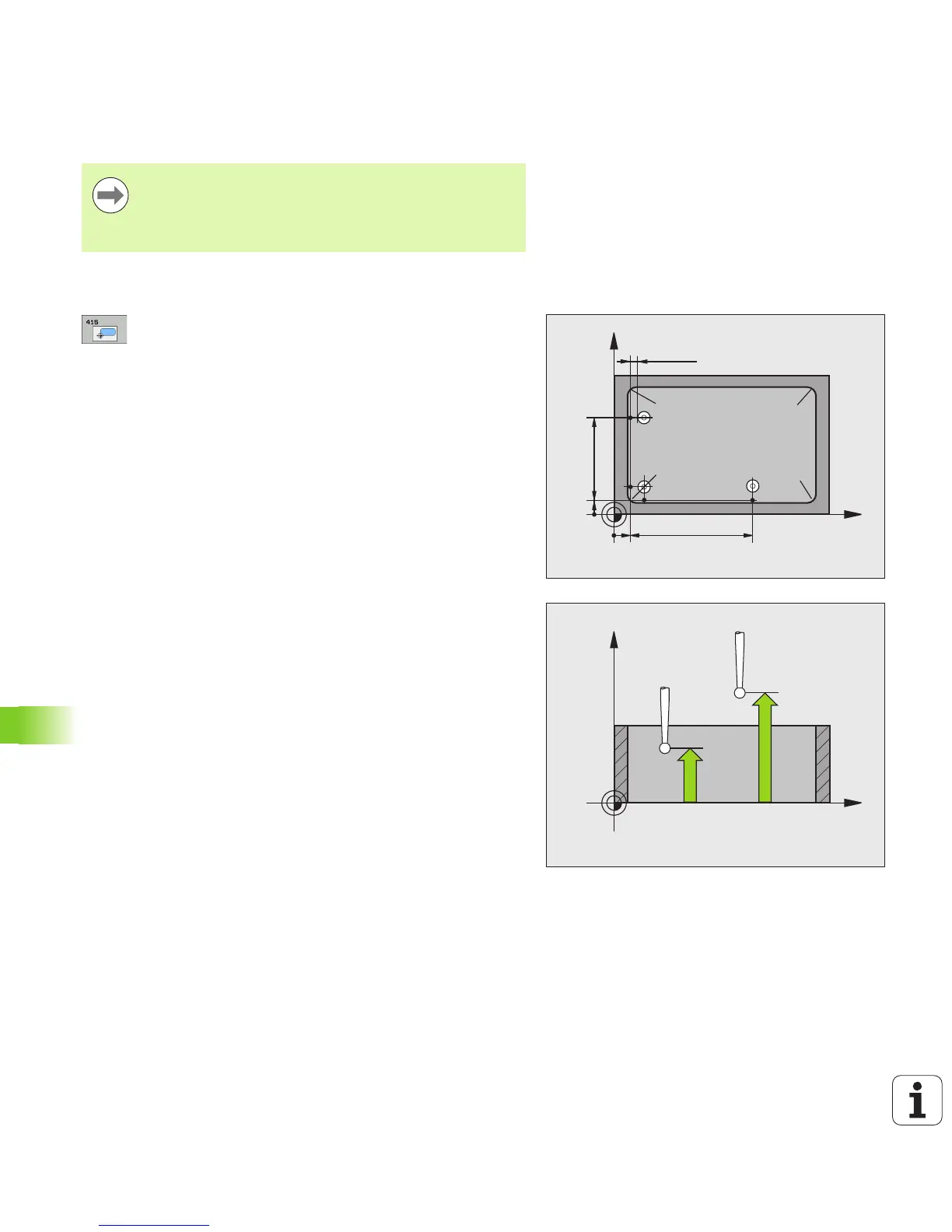

U Measuring height in the touch probe axis Q261

(absolute): Coordinate of the ball tip center (= touch

point) in the touch probe axis in which the

measurement is to be made. Input range -

99999.9999 to 99999.9999

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

U Clearance height Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999, alternatively PREDEF

Before a cycle definition you must have programmed a

tool call to define the touch probe axis.

The TNC always measures the first line in the direction of

the minor axis of the working plane.

Loading...

Loading...