382 Touch Probe Cycles: Automatic Datum Setting

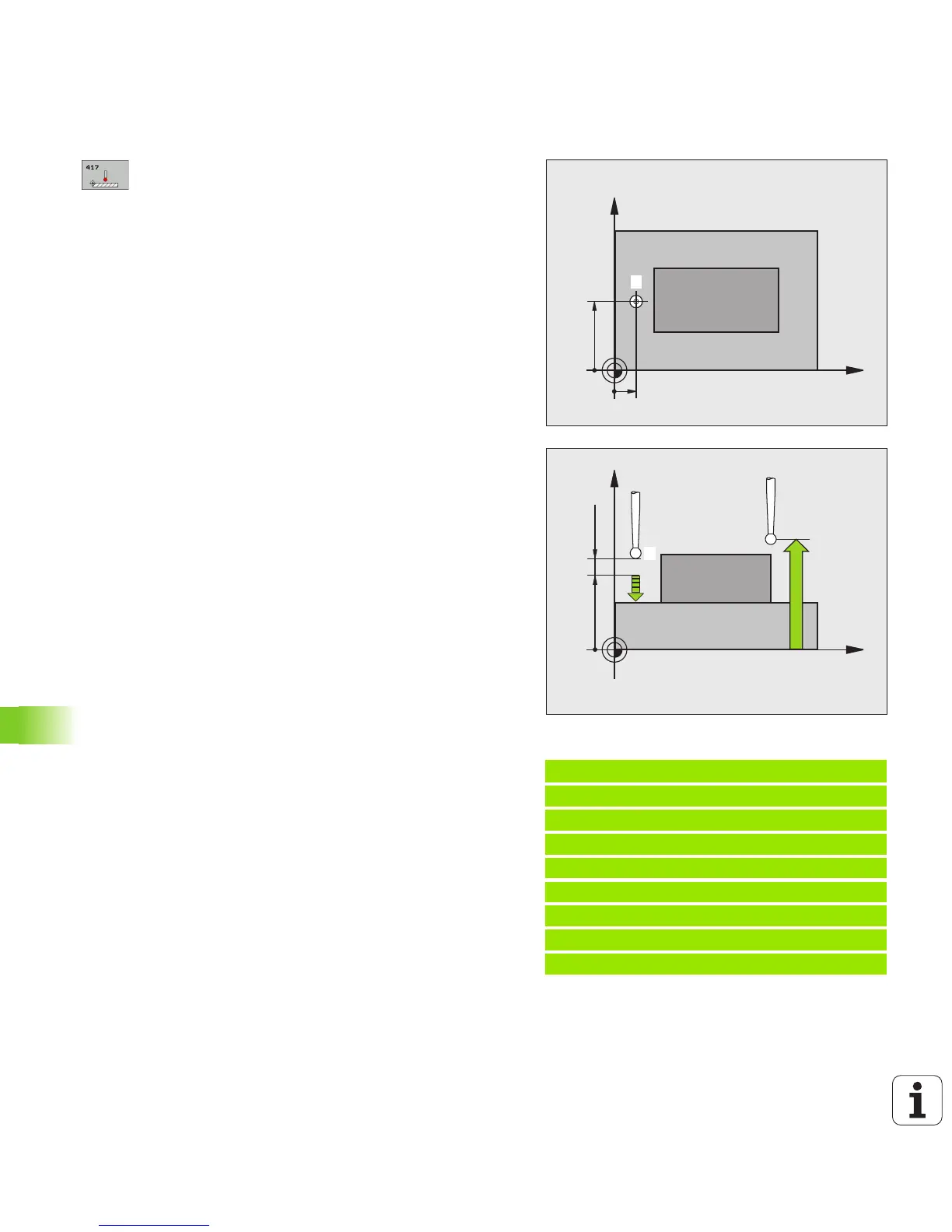

15.11 DATUM IN TOUCH PROBE AXIS (Cycle 417, DIN/ISO: G417)

Cycle parameters

U 1st meas. point 1st axis Q263 (absolute):

Coordinate of the first touch point in the reference

axis of the working plane. Input range -99999.9999 to

99999.9999

U 1st meas. point 2nd axis Q264 (absolute):

Coordinate of the first touch point in the minor axis of

the working plane. Input range -99999.9999 to

99999.9999

U 1st meas. point 3rd axis Q294 (absolute):

Coordinate of the first touch point in the touch probe

axis. Input range -99999.9999 to 99999.9999

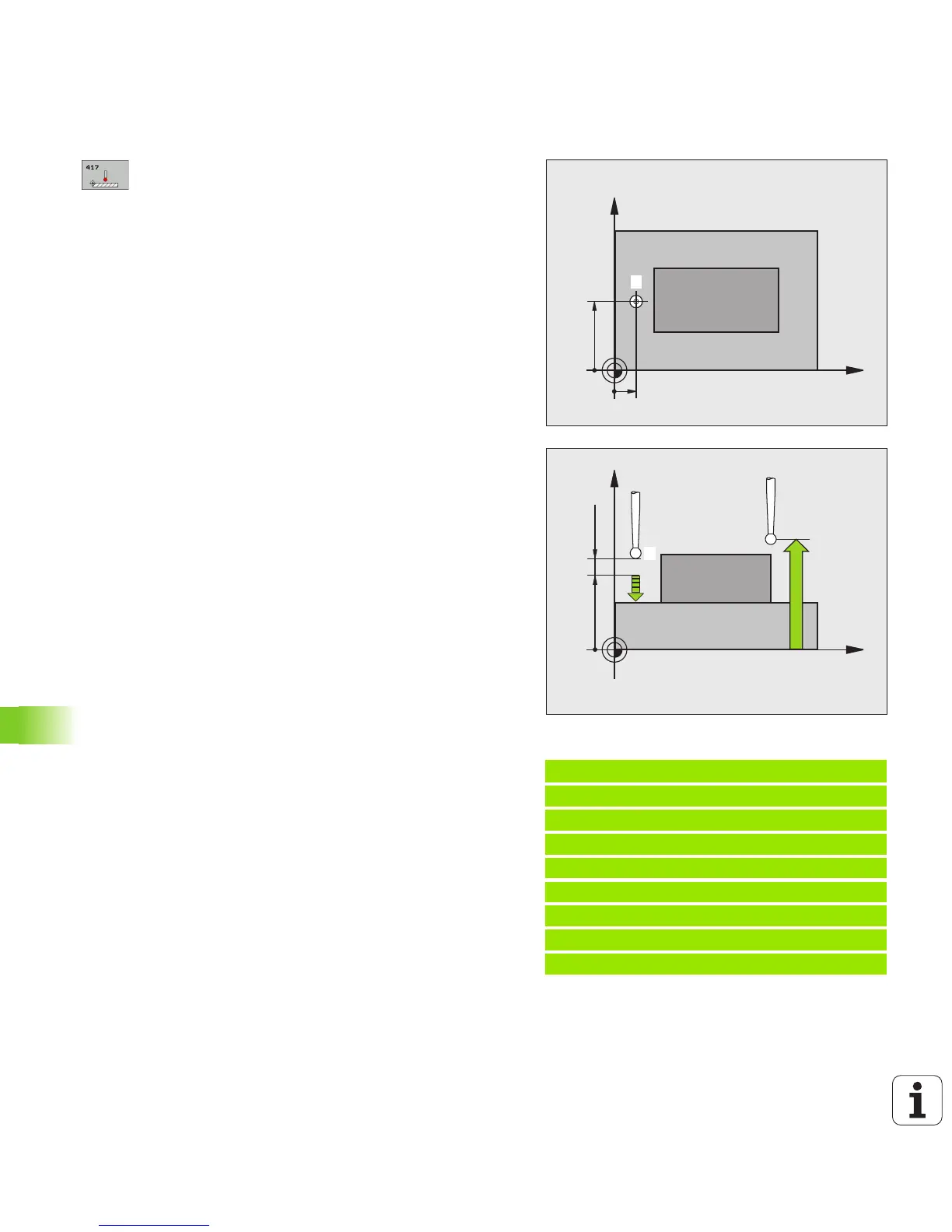

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

U Clearance height Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999, alternatively PREDEF

U Datum number in table Q305: Enter the number in the

datum or preset table in which the TNC is to save the

coordinate. If you enter Q305=0, the TNC

automatically sets the display so that the new datum

is on the probed surface. Input range 0 to 2999

U New datum in TS axis Q333 (absolute): Coordinate in

the touch probe axis at which the TNC should set the

datum. Default setting = 0. Input range: –99999.9999

to 99999.9999

U Measured-value transfer (0, 1) Q303: Specify

whether the determined datum is to be saved in the

datum table or in the preset table:

-1: Do not use. Is entered by the TNC when old

programs are read in (see “Saving the calculated

datum” on page 344).

0: Write determined datum in the active datum table.

The reference system is the active workpiece

coordinate system.

1: Write determined datum in the preset table. The

reference system is the machine coordinate system

(REF system).

Example: NC blocks

5 TCH PROBE 417 DATUM IN TS AXIS

Q263=+25 ;1ST POINT 1ST AXIS

Q264=+25 ;1ST POINT 2ND AXIS

Q294=+25 ;1ST POINT 3RD AXIS

Q320=0 ;SETUP CLEARANCE

Q260=+50 ;CLEARANCE HEIGHT

Q305=0 ;NO. IN TABLE

Q333=+0 ;DATUM

Q303=+1 ;MEAS. VALUE TRANSFER

Loading...

Loading...