410 Touch Probe Cycles: Automatic Workpiece Inspection

16.5 MEASURE HOLE (Cycle 421, DIN/ISO: G421)

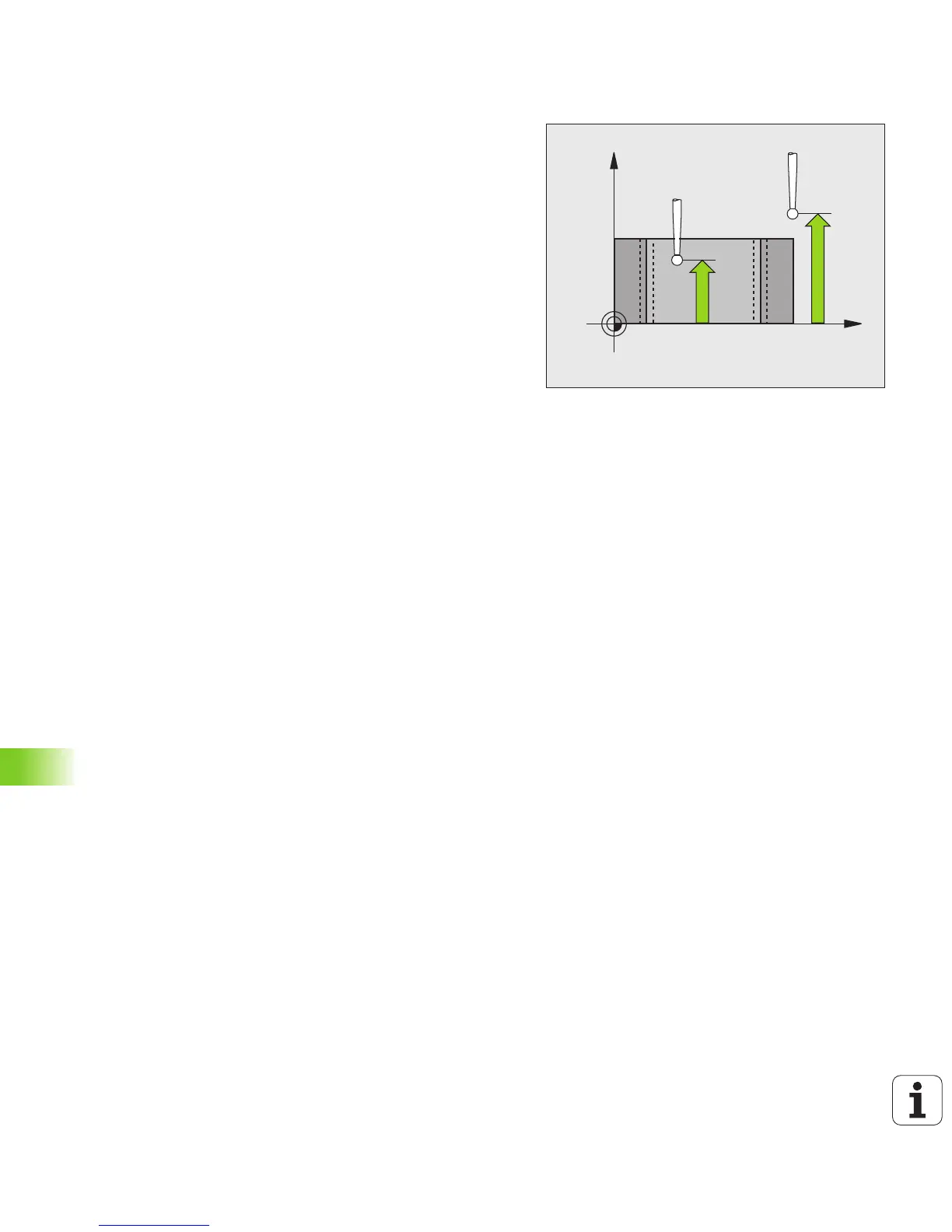

U Measuring height in the touch probe axis

Q261 (absolute): Coordinate of the ball tip

center (= touch point) in the touch probe axis in

which the measurement is to be made. Input

range -99999.9999 to 99999.9999

U Setup clearance Q320 (incremental): Additional

distance between measuring point and ball tip. Q320

is added to MP6140. Input range 0 to 99999.9999,

alternatively PREDEF

U Clearance height Q260 (absolute): Coordinate in the

touch probe axis at which no collision between touch

probe and workpiece (fixtures) can occur. Input range

-99999.9999 to 99999.9999, alternatively PREDEF

U Traversing to clearance height Q301: Definition of

how the touch probe is to move between the

measuring points:

0: Move at measuring height between measuring

points

1: Move at clearance height between measuring

points

Alternatively PREDEF

U Maximum limit of size for hole Q275: Maximum

permissible diameter for the hole (circular pocket).

Input range 0 to 99999.9999

U Minimum limit of size for hole Q276: Minimum

permissible diameter for the hole (circular pocket).

Input range 0 to 99999.9999

U Tolerance for center 1st axis Q279: Permissible

position deviation in the reference axis of the working

plane. Input range 0 to 99999.9999

U Tolerance for center 2nd axis Q280: Permissible

position deviation in the minor axis of the working

plane. Input range 0 to 99999.9999

Loading...

Loading...