Notifier SLC Wiring Manual — P/N 51253:U9 12/3/2021 17

SLC Capacity Introduction

1.6.12 ACPS-2406 Addressable Charger/Power Supply

The ACPS-2406 is an auxiliary power supply and battery charger. Each of its four Notification Appliance Circuits (NAC) is individually

addressable, eliminating the need for control modules. In addition, each circuit can provide notification appliance synchronization.

FlashScan and CLIP capable. This product has been discontinued.

1.6.13 AMPS-24 Addressable Power Supply

The AMPS-24 is a primary power supply and battery charger. Depending on its configuration, it can occupy either one or four addresses

on an SLC. FlashScan capable.

1.6.14 PMB-AUX Addressable Charger/Power Supply

PMB-AUX is an addressable primary power supply and battery charger for N16. Each unit supports up to 5 SLM-318 SLC loop cards

and provides four (4) Notification Appliance Circuits (NAC). NACs can provide notification appliance synchronization. FlashScan and

CLIP capable.

1.7 SLC Capacity

The protocol selected for an SLC loop determines the maximum number of devices that can be handled by the loop (see Section 1.5,

“Polling Protocols”, on page 13). Within those limits, the individual control panel may have additional restrictions. See the specific

installation manual for this information.

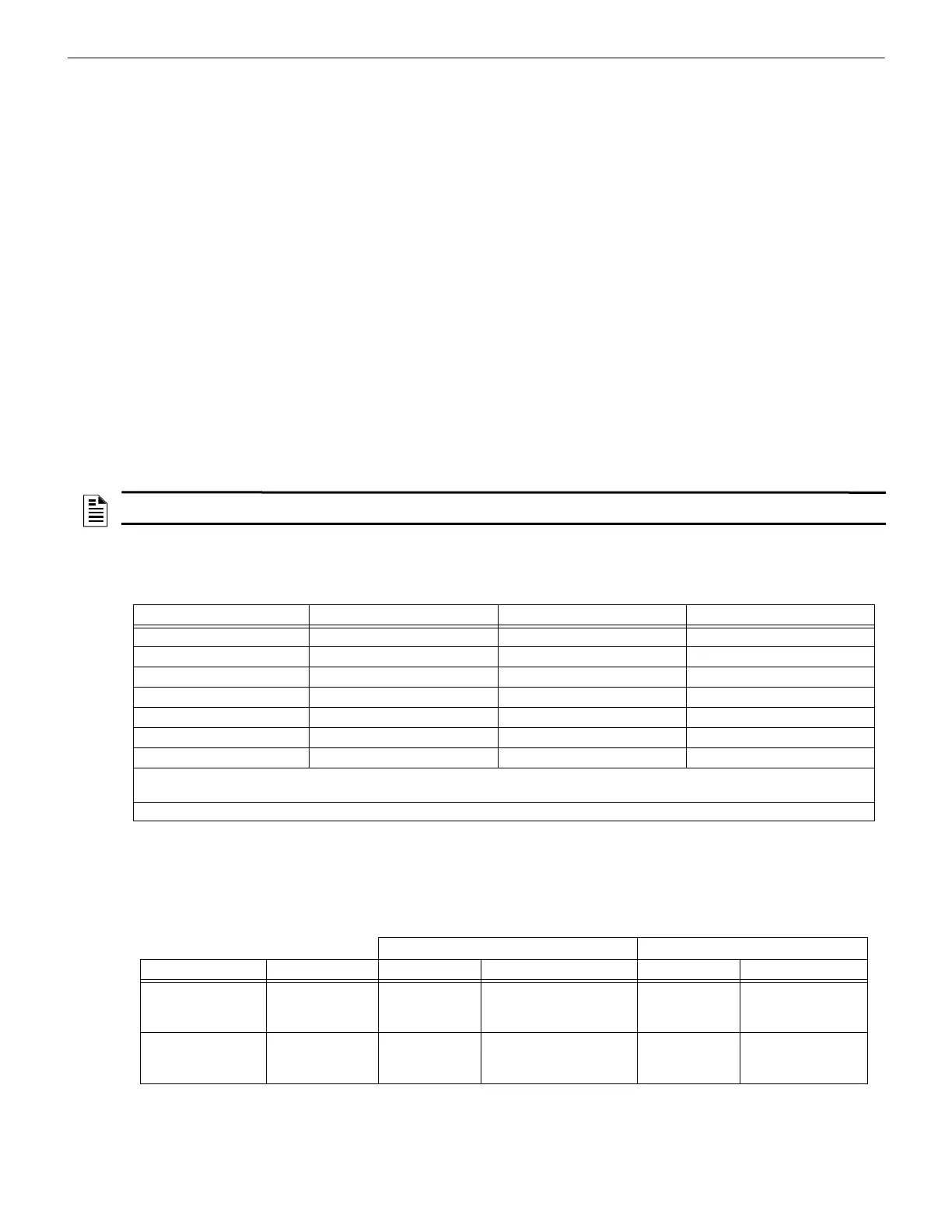

1.8 SLC Performance

SLC performance (Class B, Class A, or Class X) depends on the configuration of the circuit, the components on the circuit (see

Table 1.3), and the power supply if required for auxiliary power (see individual wiring diagrams). SLC operation meeting Class X

requirements isolates each addressable device on the SLC from faults that may occur on the SLC.

Wiring class requirements are determined by national and local codes. Consult with the Authority Having Jurisdiction before wiring the

SLC. The table below (derived from NFPA 72-2002 and NFPA 72-2013) lists the trouble conditions that result when a fault exists on an

SLC. Items with asterisks are not applicable to NFPA 72-2013. Additional information is broken out in Section 2, “Wiring Require-

ments”, on page 19, and Section 3, “Shielded Wire Termination”, on page 26.

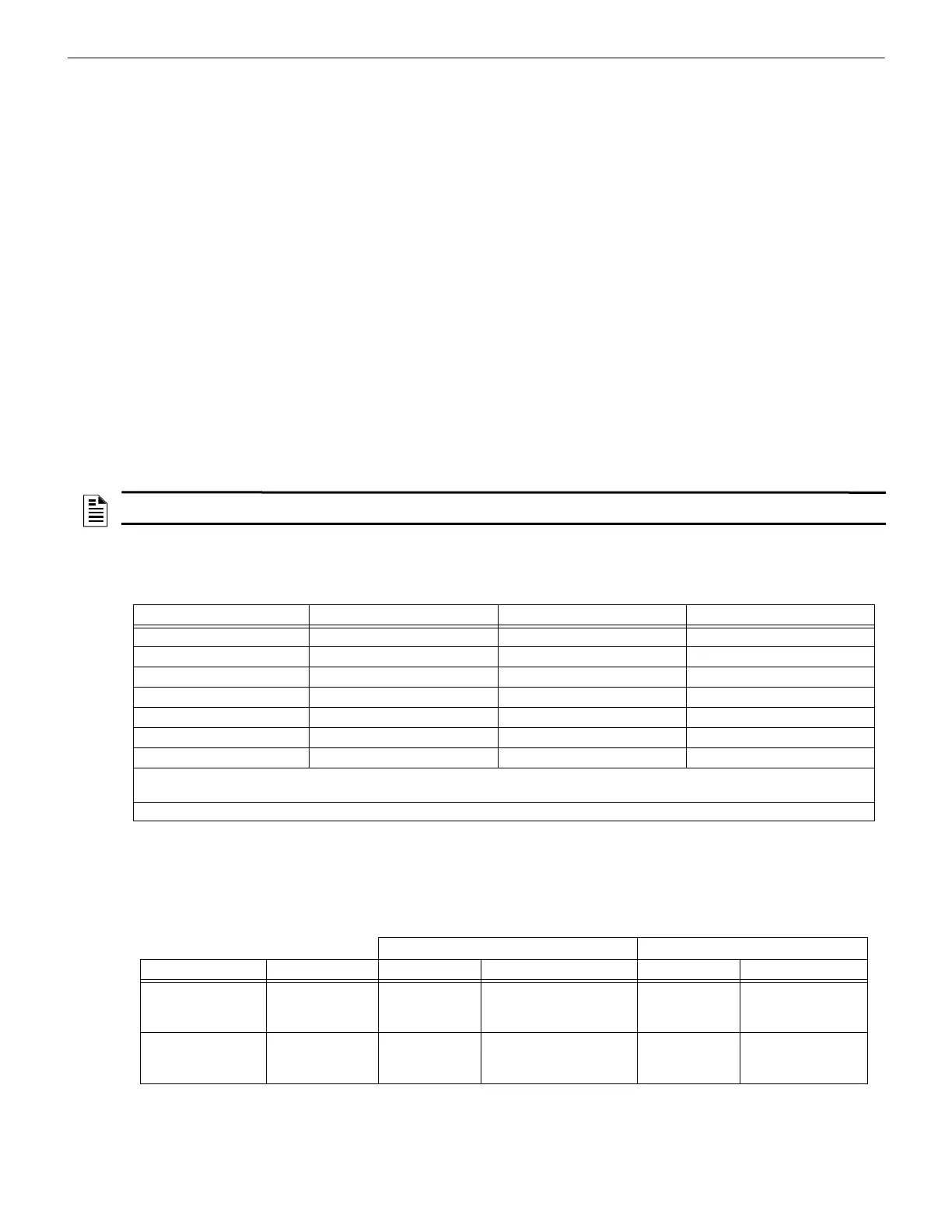

1.9 LED Operation

The table below lists the LED operation on the various devices of an SLC in CLIP (Classic Loop Interface Protocol) Mode and FlashS-

can® Mode. When switching from FlashScan® to CLIP mode, the loop circuit must be powered down for at least 30 seconds to reset

devices to CLIP mode LED operation.

NOTE: NFPA class configuration must be programmed into N16 Series panels. The panel will check that the physical wiring matches and

generate a trouble message if there is a mismatch. See panel documentation for details.

Type of Fault Class B Class A Class X

Single Open Trouble Alarm, Trouble Alarm, Trouble

Single Ground Alarm, Trouble (ground) Alarm, Trouble (ground) Alarm, Trouble (ground)

Short Trouble Trouble Alarm, Trouble

Short and open* Trouble* Trouble* Trouble*

Short and ground* Trouble* Trouble* Alarm*, Trouble*

Open and ground Trouble* Alarm*, Trouble* Alarm, Trouble

Communications loss Trouble Trouble Trouble

• Trouble - The control panel will indicate a trouble condition for this type of fault.

• Alarm - The control panel must be able to process an alarm input signal in the presence of this type of fault.

*Removed from NFPA 72-2013; included for legacy support under NFPA 72-2002 only.

Table 1.3 SLC Circuit Configuration and Performance: Class B, Class A, Class X

CLIP Mode FlashScan® Mode

Control Panel Device Standby Activated Standby Activated

AM2020

AFP1010

Monitor Module

Control Module

Detector

Blinks RED

Blinks GREEN

Blinks RED

RED continuous

2 sec. GREEN, then OFF

RED continuous

N/A

N/A

N/A

N/A

N/A

N/A

AFP-300/AFP-400 Monitor Module

Control Module

Detector

Blinks RED

Blinks GREEN

Blinks RED

RED continuous

GREEN continous

RED continuous

N/A

N/A

N/A

N/A

N/A

N/A

Table 1.4 LED Operations

Loading...

Loading...