13 ST 800 Pressure Transmitter User’s Manual Revision 15

1. Refer to Figure 10 for a representative flush-mounted transmitter installation. Cut a hole for a one

(1) inch standard pipe in the tank or pipe at the transmitter mounting site.

2. Weld the 1-inch mounting sleeve to the tank wall or to the hole you cut in the pipe.

3. Insert the transmitter meter body into the mounting sleeve and secure it with the locking bolt.

4. Tighten the bolt to a torque of 4 Nm +0.3 Nm (4.7 pound-feet +0.2 pound-feet).

3.4.7 Remote Diaphragm Seal Mounting Information

The combination of tank vacuum and high pressure capillary head effect should not

exceed nine (9) psi (300 mmHg) absolute. For insulated tanks, be sure to remove enough

insulation to accommodate the flange extension. The end user is responsible for supplying a

flange gasket and mounting hardware suitable for the service condition of the transmitter.

Mount the transmitter flanges within the limits in for the fill fluid in the capillary tubes, with a

tank at one (1) atmosphere.

Table 4 – Flange Mounting Guidelines

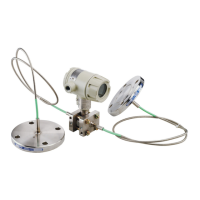

Refer to Figure 11 for a representative remote diaphragm seal installation. Mount the transmitter at a

remote distance determined by the length of the capillary tubing.

Figure 11 – Representative Remote Diaphragm Seal Transmitter Installation

Note: Lower flange seal should not be mounted over 22 feet below or above the transmitter for silicone

fill fluid (11 feet for CTFE fill fluid) with tank at one atmosphere. The combination of tank vacuum and

high-pressure capillary head effect should not exceed 9 psi vacuum (300 mmHg absolute).

Depending on transmitter model, connect the remote seal to the tank shown in Table 5.

Loading...

Loading...