viii ST 800 Pressure Transmitter User’s Manual Revision 15

List of Figures

Figure 1 – ST 800 Major Assemblies ..................................................................................................................................... 2

Figure 2 – Electronics Housing Components .......................................................................................................................... 2

Figure 3 –Typical ST 800 Name Plate .................................................................................................................................... 3

Figure 4 – Typical Bracket Mounted and Flange Mounted Installations ................................................................................ 8

Figure 5 – Angle Mounting Bracket Secured to a Horizontal or Vertical Pipe ....................................................................... 9

Figure 6 – Inline Model Mounted to an Optional Bracket .................................................................................................... 10

Figure 7 – Rotating the Electronics Housing ........................................................................................................................ 10

Figure 8 – Using a Spirit Balance to Level a transmitter ...................................................................................................... 11

Figure 9 – Tank-Flange Mounted transmitter ....................................................................................................................... 12

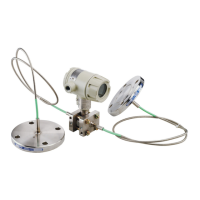

Figure 10 – Typical Flush and Flange Mounted Installations ............................................................................................... 12

Figure 11 – Representative Remote Diaphragm Seal Transmitter Installation ...................................................................... 13

Figure 12 – Typical 3-Valve Manifold with Blow-Down Piping ......................................................................................... 14

Figure 13 – Flange Adapter Removal and Replacement ....................................................................................................... 16

Figure 14 – Transmitter Operating Ranges ........................................................................................................................... 16

Figure 15 – Transmitter 3-Screw Terminal Board and Grounding Screw ............................................................................ 17

Figure 16 – Current Loop Test Connections ......................................................................................................................... 20

Figure 17 – Three-Button Option ......................................................................................................................................... 22

Figure 18 – Locating the Failsafe and Write Protect Jumpers .............................................................................................. 82

Figure 19 – Basic Display with Process Variable Format ..................................................................................................... 84

Figure 20 – Standard Display with Process Variable Format ............................................................................................... 84

Figure 21 – Advanced Display Formats with the Process Variable ...................................................................................... 85

Figure 22 – DP Transmitter Head Disassembly .................................................................................................................... 89

Figure 23 – Head Bolt Tightening Sequence ........................................................................................................................ 90

Figure 24 – PWA Replacement ............................................................................................................................................ 91

Figure 25 – Disassembly for Meter Body Replacement ....................................................................................................... 93

Figure 26 – Hardware Location to Remove the Meter Assembly ......................................................................................... 94

Figure 27 – Meter Body Reassembly .................................................................................................................................... 95

Figure 28 – Head Bolt Tightening Sequence ........................................................................................................................ 95

Figure 29 – Local Display Fault Diagnostic Conditions ....................................................................................................... 98

Figure 30 – Angle and Flat Bracket Parts ........................................................................................................................... 101

Figure 31 – Electronic Housing, Display End ..................................................................................................................... 102

Figure 32 – Electronic Housing, Terminal Block End ........................................................................................................ 103

Figure 33 – Transmitter Major Assemblies ......................................................................................................................... 104

Figure 34 - ST 800 Models STD810, 820, 825, 830, & 870 ............................................................................................... 107

Figure 35 – STG830, 840, 870, and STA822, 840 Transmitter Body ................................................................................. 110

Figure 36 – Inline Gauge and Inline Atmospheric Display Bodies .................................................................................... 111

Figure 37 – Flush Mount Meter Body................................................................................................................................. 111

Figure 38 a – Extended Flange Design ............................................................................................................................... 112

Figure 39 – Pseudo Flange design ...................................................................................................................................... 113

Figure 40 – Remote Seal Diaphragm .................................................................................................................................. 113

Loading...

Loading...