MX3657-01 Rev. D ©2020 General Maintenance

hysecurity.com | 800-321-9947 117

MeChniCal Controls

Stopping the Gate

Most models (except StrongArm 15 and 40) employ a time delay

Soft Stop system. Additionally, brake valves are used to control the

stopping of heavy or fast moving gates. These valves are exclusive

to HySecurity operators. They are independently adjustable to

allow the gate to stop predictably and without banging.

Starting the Gate

To accommodate for loads moving beyond one foot per second,

it is necessary to Soft Start the load gently and stop it smoothly.

HySecurity accomplishes Soft Start with another exclusive feature

we call an Accumulator With Out Gas (AWOG), which diverts

some of the start-up hydraulic ow, accommodates for the load,

and starts the gate smoothly, similar to letting your foot slowly off

a car clutch without any lurching.

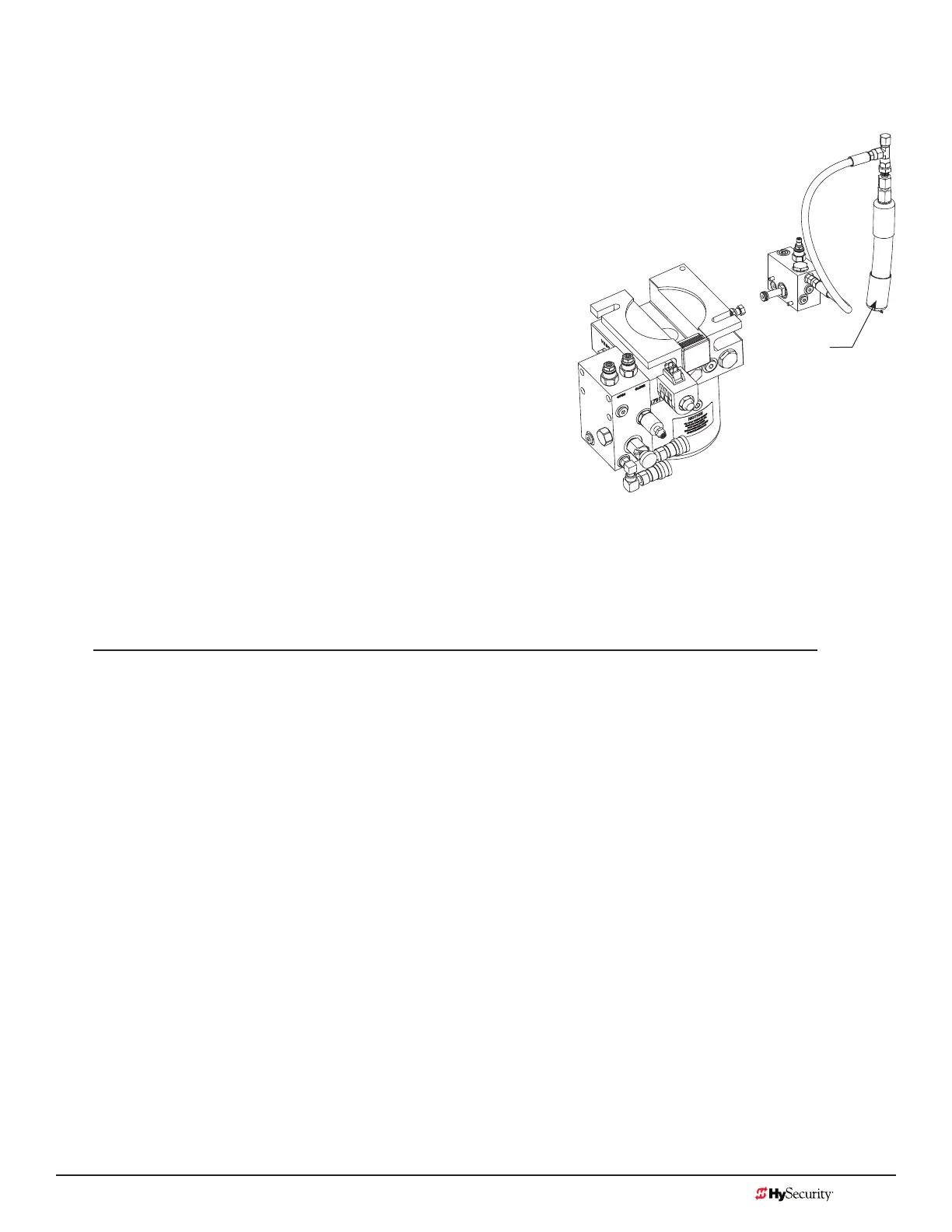

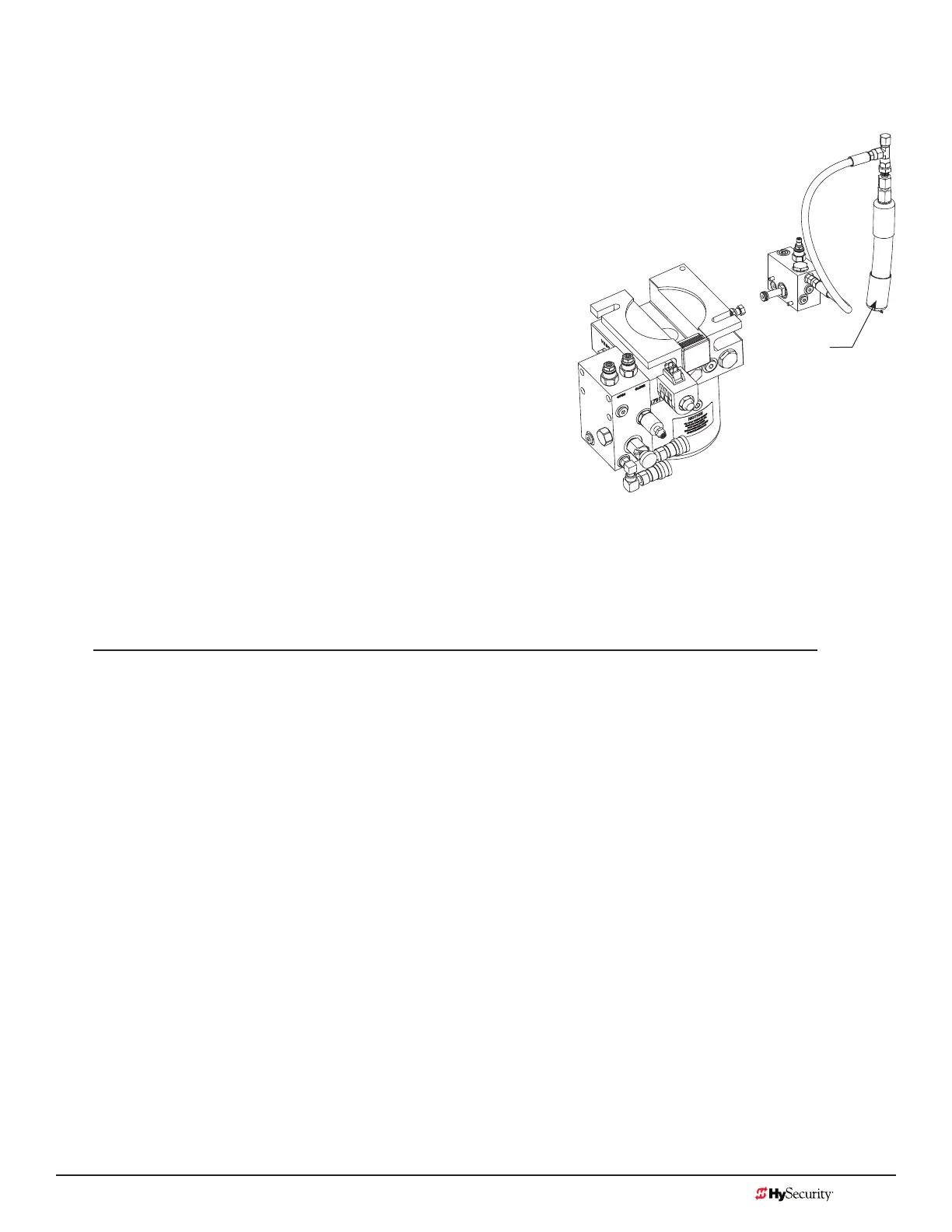

The downward facing AWOG (shown right) improves the life and

performance of a gate system and never needs adjustment.

MeChaniCal MaintenanCe

NOTICE: Before checking the internal mechanisms of the operator, turn off all power switches.

The mechanical maintenance for the StrongArm is not in depth or difcult, but should be performed on a

routine basis.

Schedule regular maintenance:

Check for signs of rust. The operator chassis is zinc plated which is corrosion-resistant, but some

environments may increase the rate of corrosion. If any areas of rust are found, reduce the spread of

corrosion by treating the areas with a rust inhibitor.

Grease the hydraulic cylinder every 50,000 cycles. Use NLGI #2 Grade Moly EP (Extreme Pressure)

lithium base grease only and apply it with a standard grease gun. Grease other main shaft bearings

every 100,000 cycles.

Check the motor. DC motors contain carbon brushes which wear over time and must be replaced.

Failure to replace the brushes will result in damage to the DC motor. Brushes should be inspected

every year in high usage applications or every 100,000 cycles and replaced as needed.

Replace worn-out batteries. Refer to Clock Battery Replacement on page 116.

eliminated which reduces drive wheel wear and drag in misaligned gate installations. Additionally, the no-

AWOG

Loading...

Loading...