5 - 41

XTC/3 Operating Manual

5.3.5.4 XTC/2 UPDATE Command

The Update command replaces the current parameter value with the DATA Sent.

To update film parameters the format of the update command is:

U pp F vvv - Parameter pp of film F, value vvv.

Update parameter pp of film F, with value vvv, a space is used as a delimiter

between the pp and F values as well as the F and vvv values, where F is a digit

between 1 and 9. Refer to Table 5-7 for a numbered list of parameters and their

limits. If value vvv is left blank, the command will be accepted and a value of 0 will

be transmitted.

NOTE: If pp is set to 99, the data is a list of all parameters in the order specified.

This command allows a rapid block transfer of data which is convenient for

downloading films. Each parameter value must be separated by a space.

To update layers, the format of the update command is:

U 40 L v

Where 40 designates a layer is to be updated. The value L indicates which layer to

update. The value of L can be 1, 2, or 3, and v designates the film number to insert

into layer L.

For example, the update command

U 40 1 4

will enter film number 4 into layer 1.

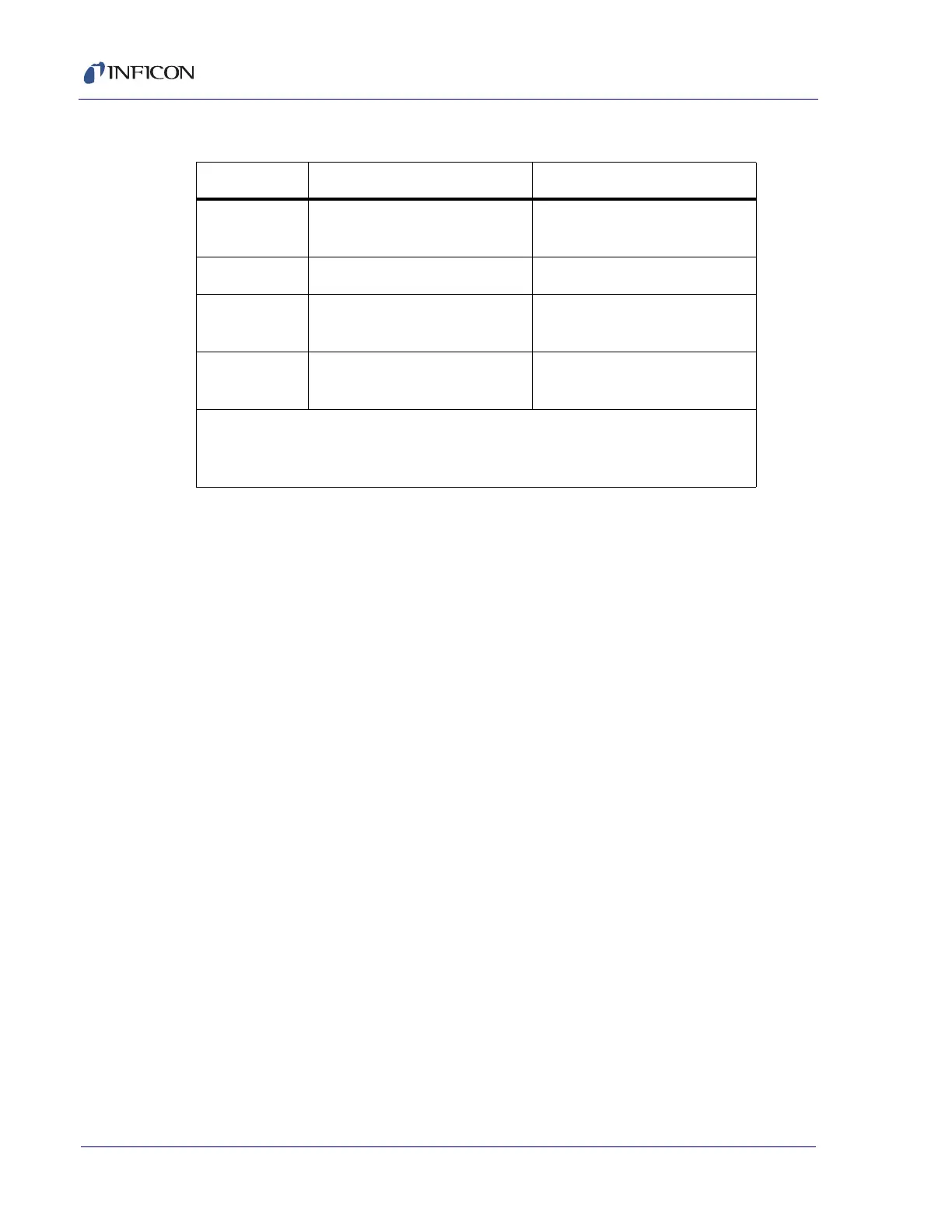

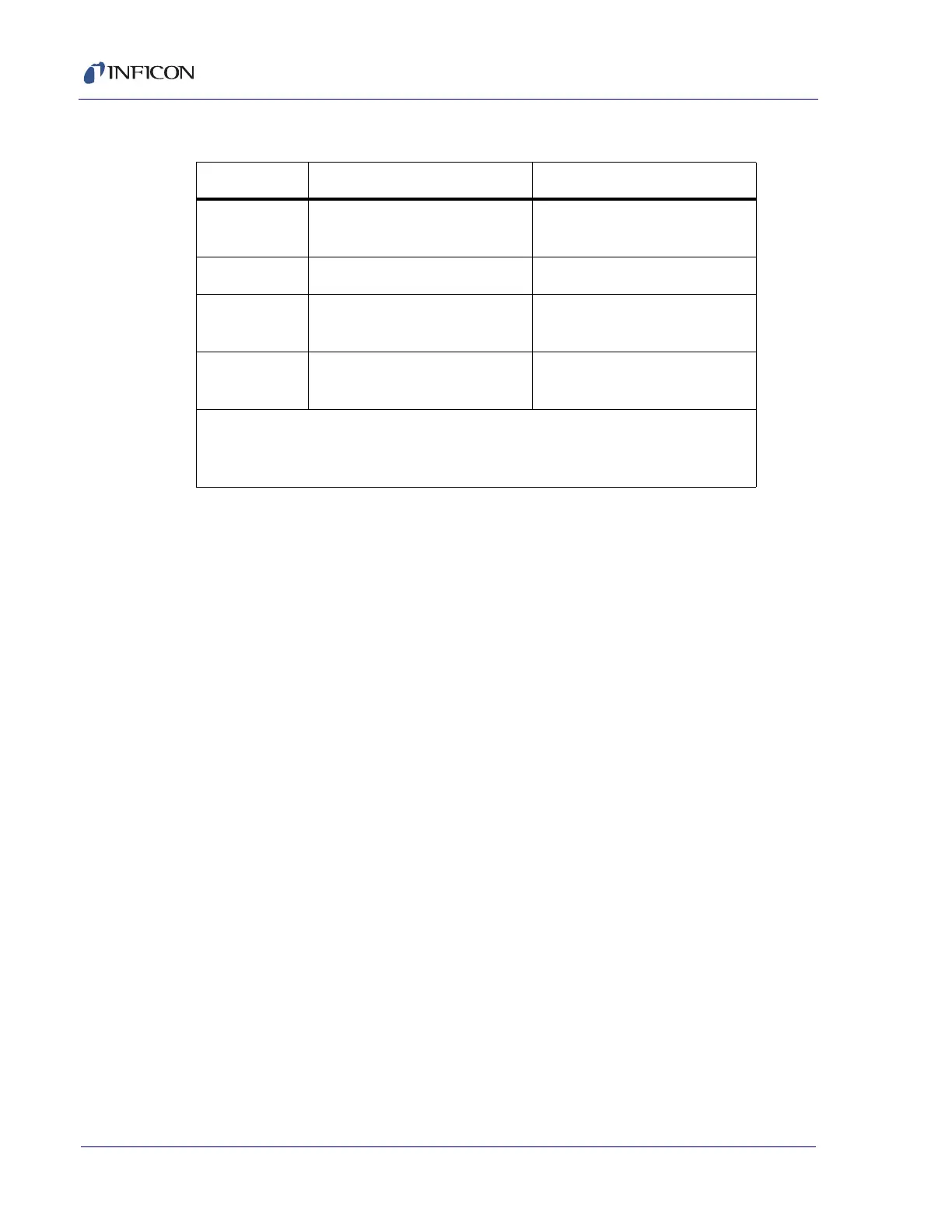

Table 5-8 Q40 command responses

Command XTC/3S Response XTC/3M Response

Q40 0 "a 0 0 " (a = 1 to 9,

0 = no film in layer)

"a b c" (a = 1 to 32, b = 0 to 32,

c = 0 to 32)

Q40 1 "a" (a = 1 to 9) "a" (a = 1 to 32)

Q40 2 "No Data" error "b" if b = 1 to 32

"No Data" error if b = 0

Q40 3 "No Data" error "c" if c = 1 to 32

"No Data" error if c= 0

a = Film # in Layer 1

b = Film # in Layer 2

c = Film # in Layer 3

Loading...

Loading...